Device for axial retention of vanes mounted on a turbomachine rotor disc

A technology of axial retention and rotor disk, applied in the direction of blade support elements, mechanical equipment, engine elements, etc., can solve the problems of increasing the total weight of the turbine, inaccessible to bolt parts, etc., and achieve the effect of easy manufacturing and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

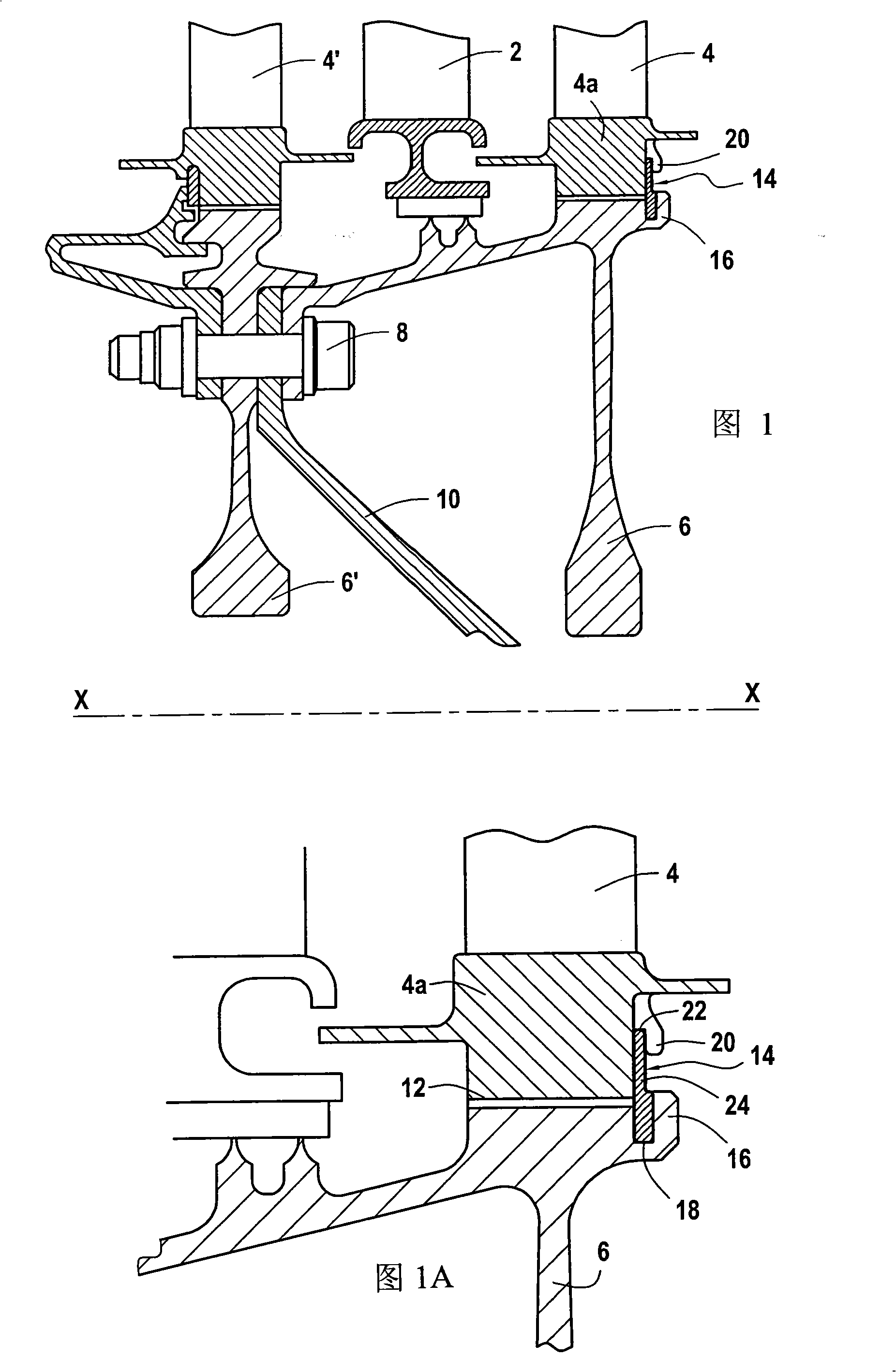

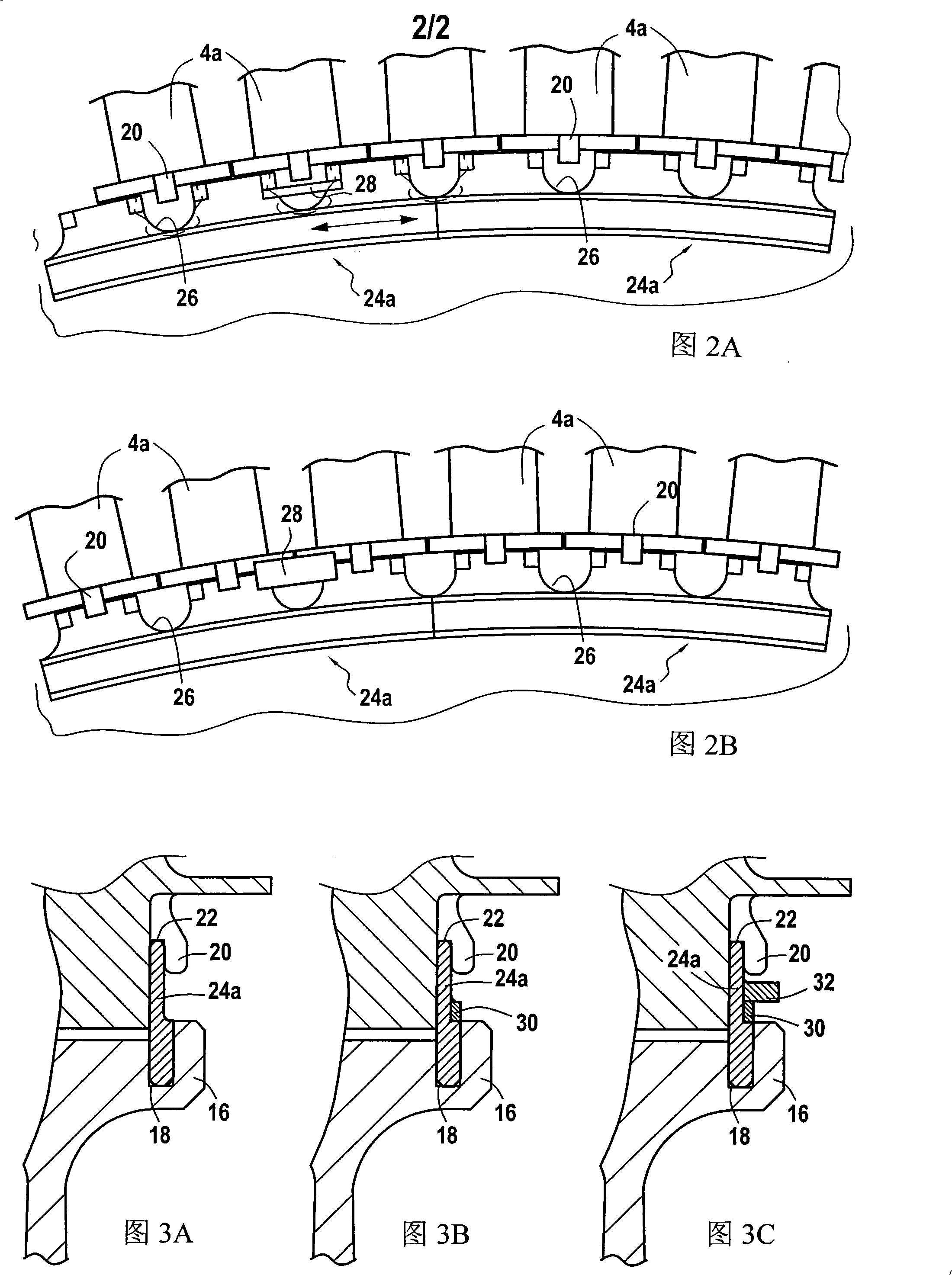

[0018] Figures 1 and 1A are partial longitudinal sectional views of a low-pressure turbine of an aviation turbine equipped with a device constituting an embodiment of the invention.

[0019] Naturally, the invention is applicable to any turbomachine installation (aerial or terrestrial) with a rotor disk on which blades are mounted by axial displacement.

[0020] The low pressure turbine is centered on the longitudinal axis X-X of the turbine. The final stage of the turbine comprises a nozzle consisting of a plurality of stator blades 2 and a rotor wheel placed behind the nozzle and consisting of a plurality of rotor blades 4 axially mounted on a rotor disk 6 . The next last pole of the turbine also has nozzles (not shown) and a rotor wheel formed by a plurality of rotor blades 4' mounted on a rotor disk 6'.

[0021] The disks 6 and 6' of the second and last stages of the turbine are fastened to each other by bolted connections 8 and they are fixed by annular trunnions 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com