Pulse laser forming method and device of thin-wall corrugated tube

A technology of pulsed laser and bellows, applied in laser welding equipment, metal processing equipment, welding equipment, etc., to achieve the effects of large processing flexibility, improved fatigue life, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

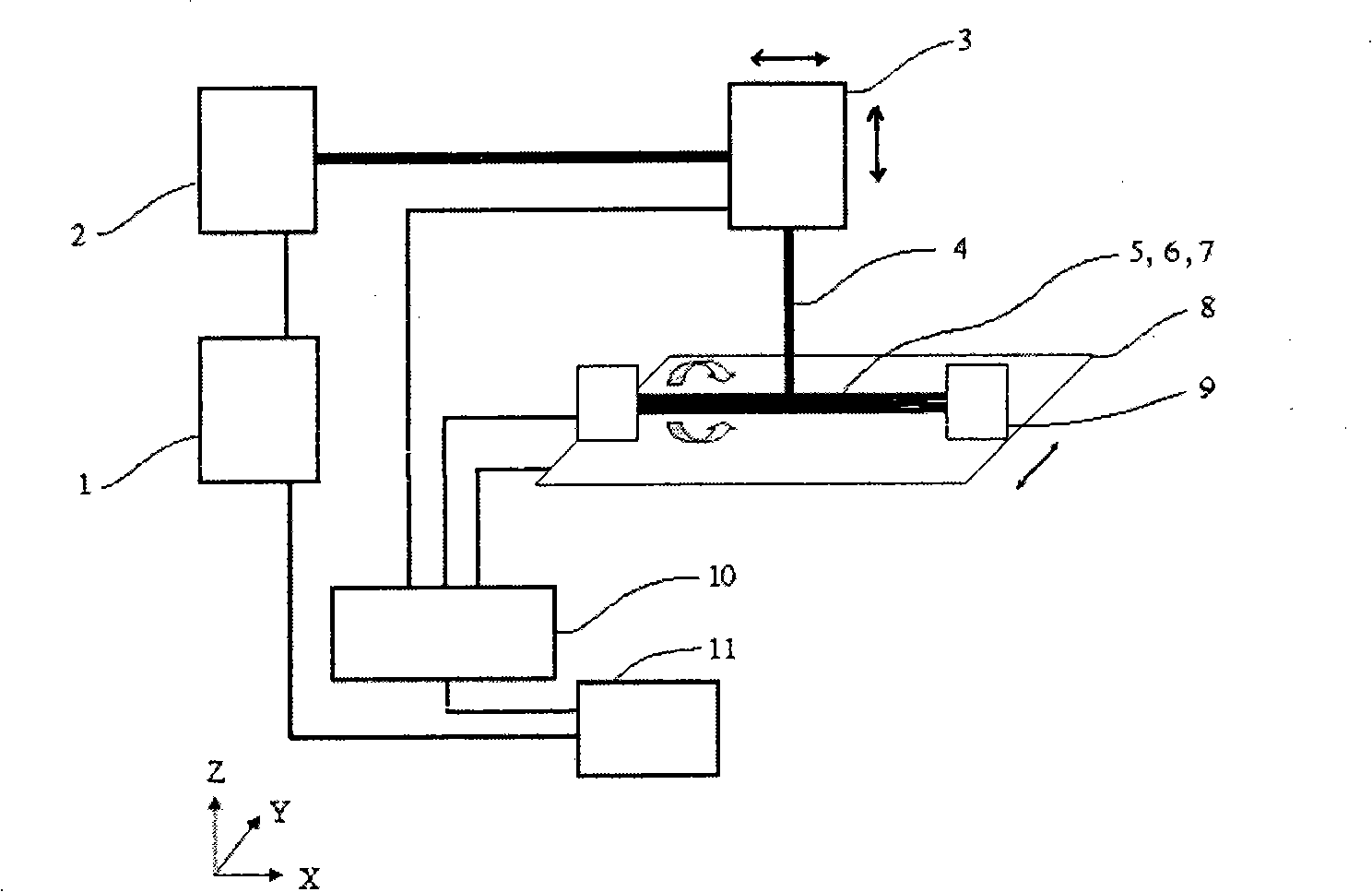

[0029] The energy size, laser mode, pulse width, pulse frequency, and pulse number of the laser beam 4 are regulated and controlled by the laser generator control system 1 . The spot diameter of the laser beam is adjusted by moving the laser head 3 in the Z direction and controlled by the motion control system 10 . The motion control system 10 simultaneously controls the movement of the laser head 3 in the X direction, the movement of the worktable 8 in the Y direction, and the rotation of the small chuck 9 on the worktable 8 . The movement in each direction makes the workpiece system and the laser beam 4 move relative to each other at a predetermined speed and trajectory through interpolation, so as to perform multi-point impact in an orderly manner.

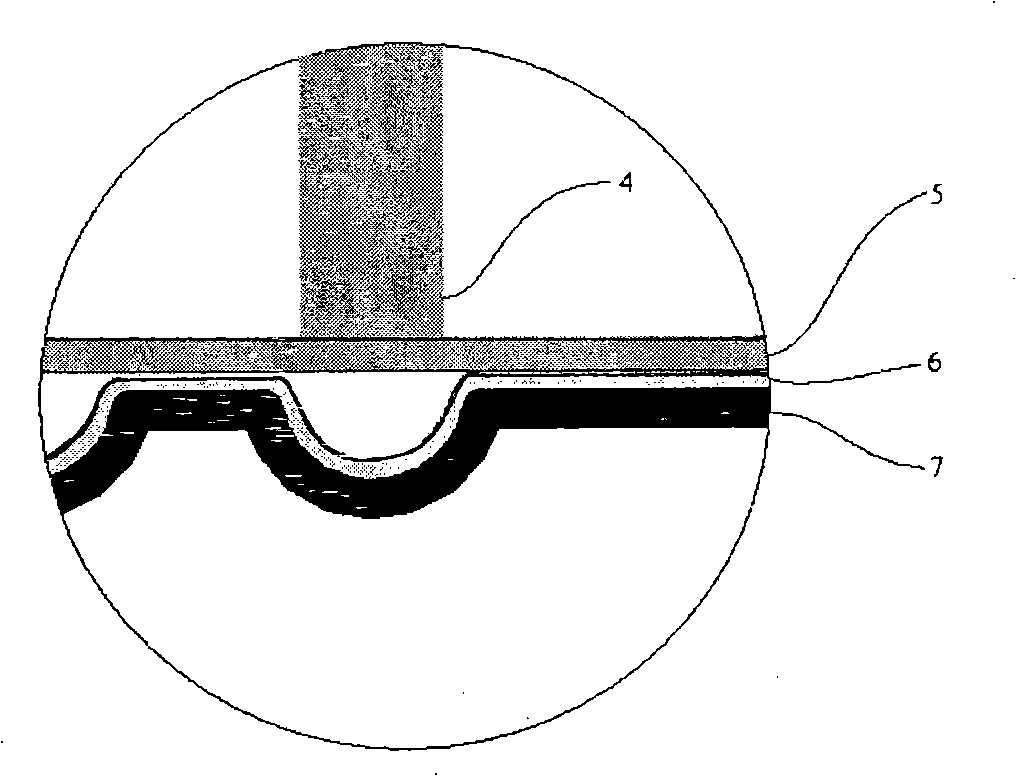

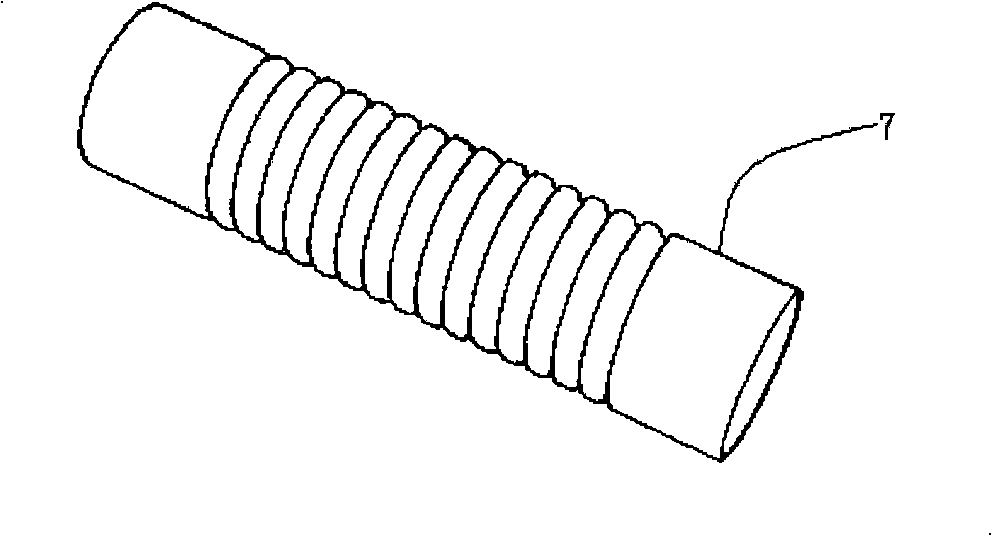

[0030] figure 2 yes figure 1 A partial cross-sectional schematic diagram of the workpiece system in the medium, which includes a constrained layer 5, an energy absorbing layer 6, and a pipe 7, and the energy absorbing layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com