Preheating method and apparatus for glass batch

A glass batching and preheating device technology, applied in glass production and other directions, can solve problems such as large heat energy and consumption, achieve good economic benefits, expand profit space, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

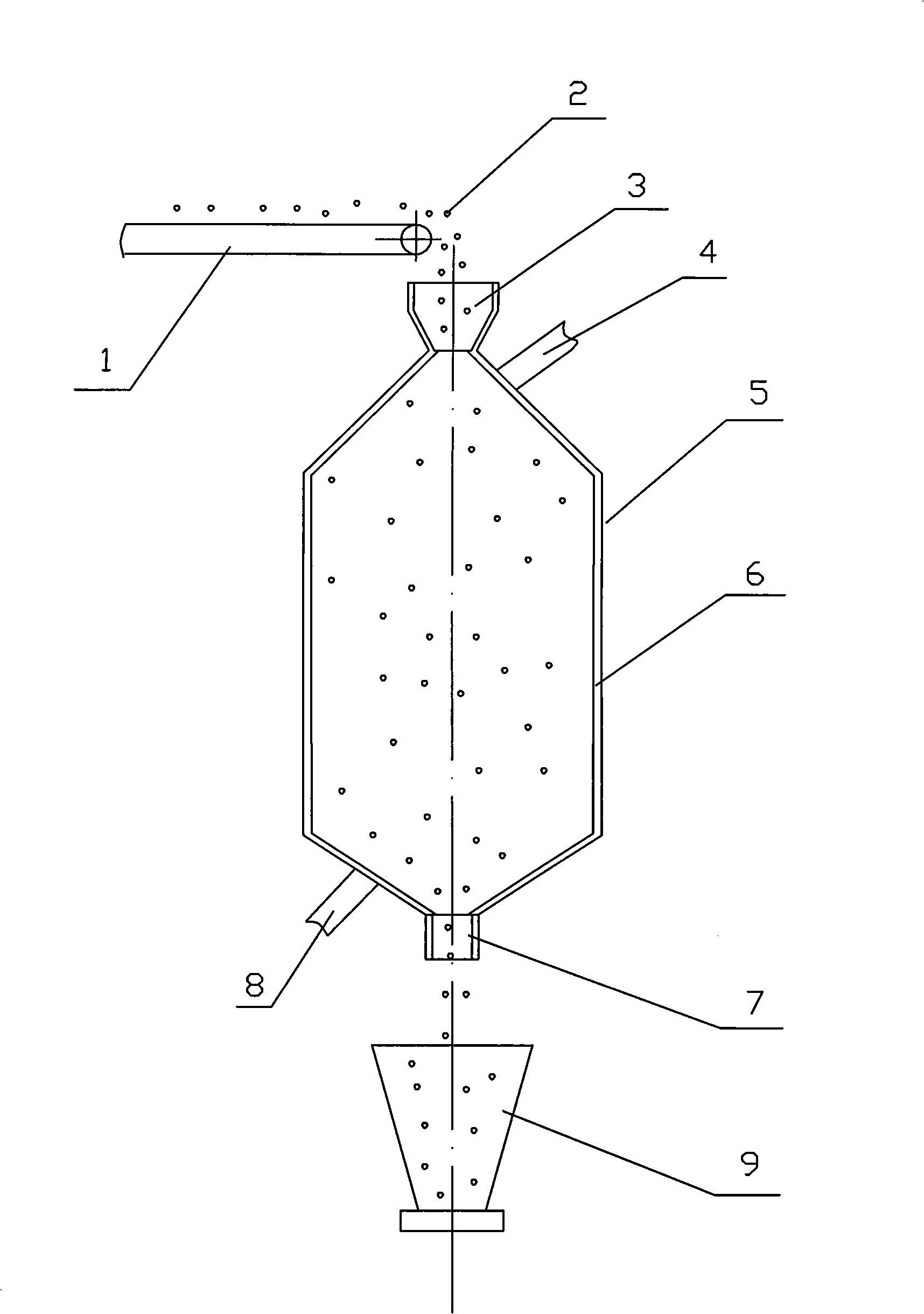

[0013] Such as figure 1 As shown, the method of the present invention firstly includes a batch preheating device, which is a container with an interlayer consisting of an inner shell 6 and an outer shell 5, and the upper and lower ends of the inner shell are respectively provided with feed ports 3 And the discharge port 7, the upper and lower parts of the casing are respectively provided with a flue gas outlet 4 and a flue gas inlet 8 to communicate with the interlayer. The flue gas inlet 8 communicates with the furnace flue gas outlet, and the flue gas outlet 4 communicates with the chimney. The flue gas is introduced into the flue gas inlet of the lower part of the preheating device from the furnace by the hot air chimney and flows out from the flue gas outlet.

[0014] The method of the present invention is as follows, various raw material components are accurately weighed by an electronic scale, mixed to form a batch 2, transported to the top of the preheating device by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com