Method for transferring a micron pattern on an optical pattern and the thus obtained optical pattern

A micron-scale, patterned technology that is used in the field of optical articles, optical lens type products, and spectacle lens types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

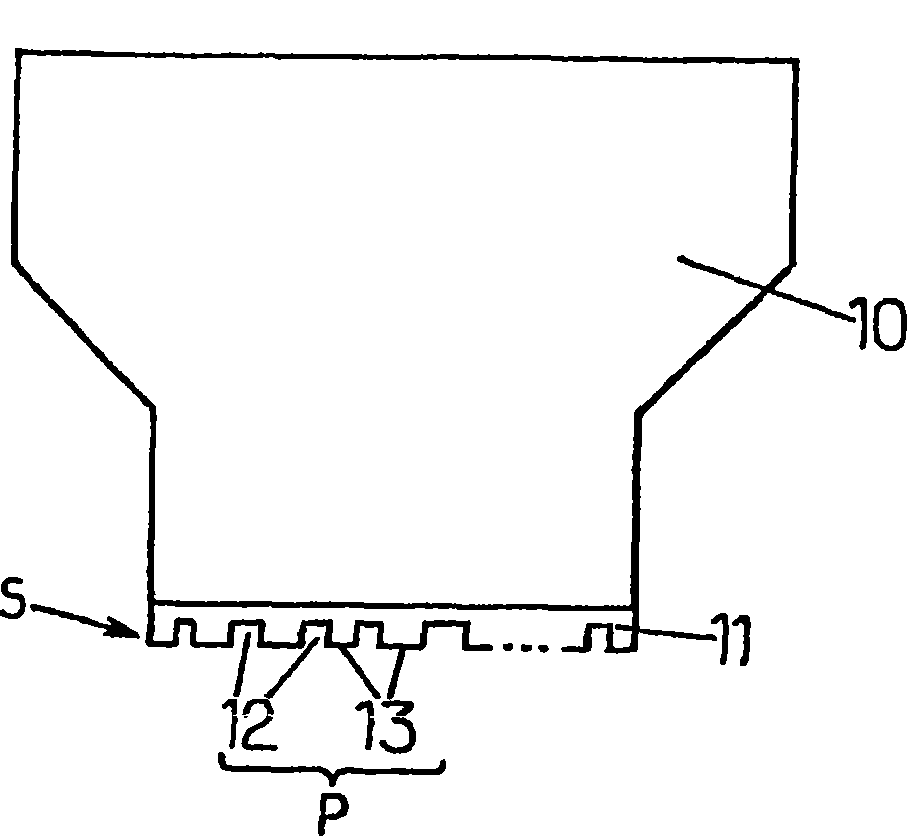

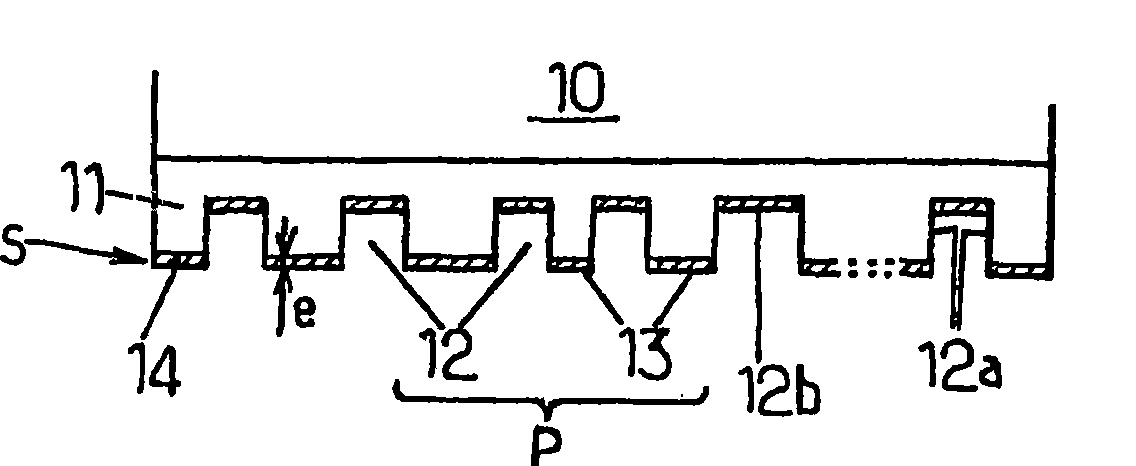

[0107] If the pressure is less than a pressure P limit : The transfer is selective; this is the first embodiment according to the invention: Amplitude hologram.

[0108] If the pressure is greater than a pressure P limit : A complete transfer occurs, accompanied by a permanent impression of the rubber layer, replicating the micro-reliefs complementary to the micro-reliefs composing the stamp pattern P on the stamp.

[0109] The P limit It is determined for a 30nm gold or aluminum layer on rubber deposited under the above conditions.

[0110] P limit is 45g / mm of the surface of the stamp protrusions 13 that make up the pattern P 2 ~60g / mm 2 pressure.

[0111] The table below shows the results under different test conditions:

[0112]

[0113] Pressure applied to selectively transfer gold example:

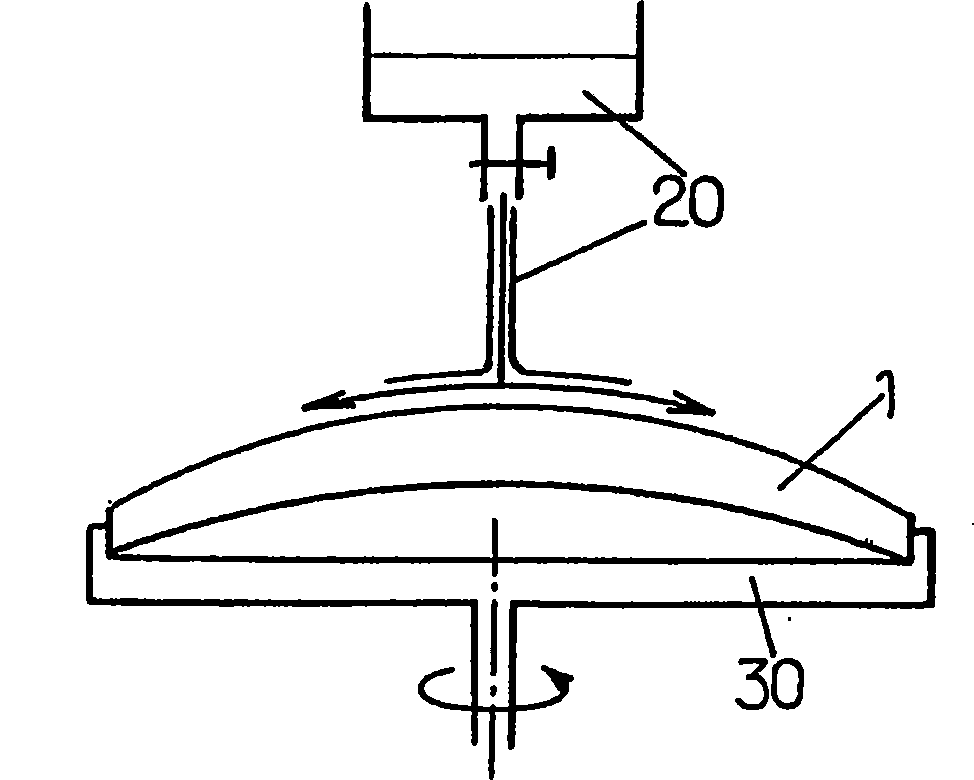

[0114] The stamper is applied to the convex surface of an ophthalmic lens covered with a layer of rubber deposited under the above conditions (the radius of curvature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com