Thin-film transistor array substrate and preparation method thereof

A technology of thin film transistors and array substrates, which is applied in the field of thin film transistor array substrates with photosensors and its production, can solve problems such as photocurrent attenuation and affect the reliability of photosensors, and achieve cost savings, improved photocurrent characteristics, The effect of increasing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

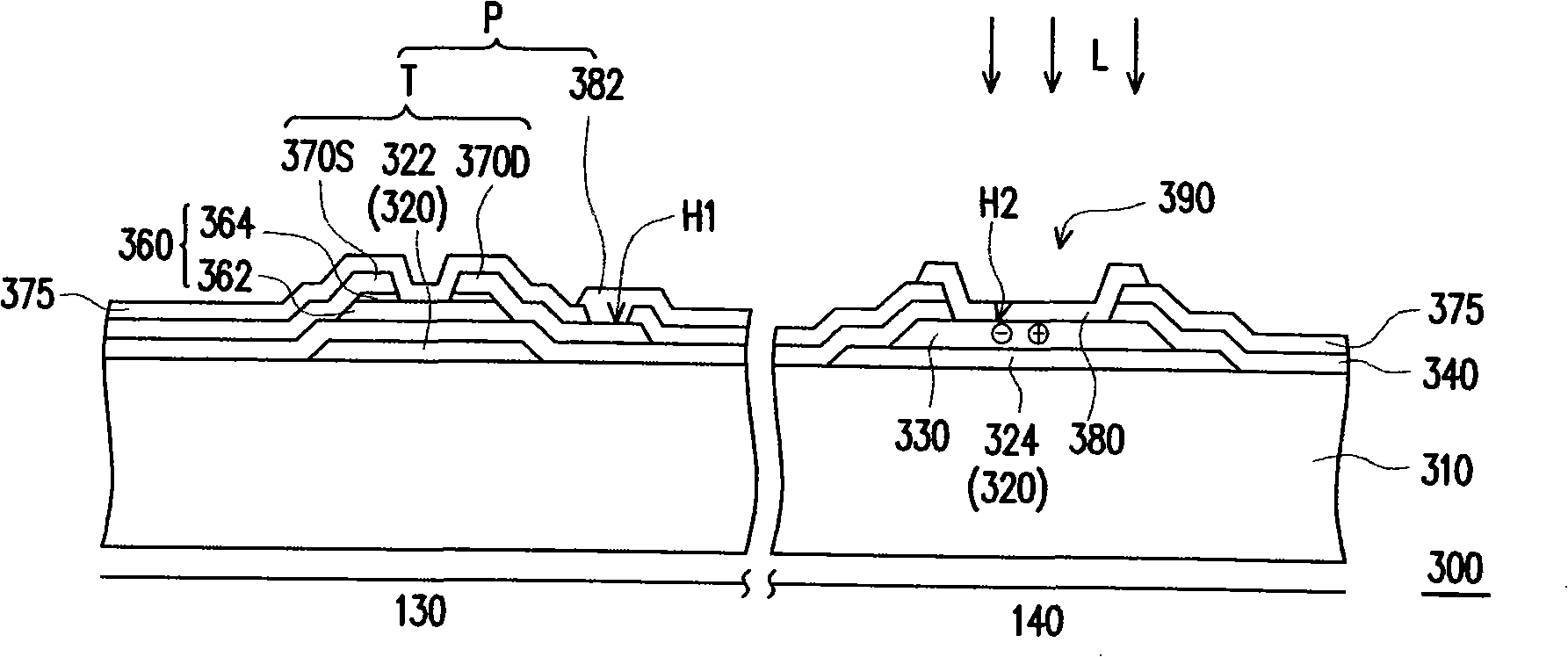

[0075] Please refer to Figure 1A and Figure 1B , which respectively illustrate the layout of a thin film transistor array substrate integrated with photosensors according to an embodiment of the present invention. Please refer to Figure 1A The thin film transistor array substrate 100 at least has a display area 110 and a peripheral circuit area 120 located on the periphery of the display area 110 . The display area 110 has a plurality of pixel areas 130 arranged in an array. When the TFT array substrate 100 is applied to a liquid crystal display, the plurality of pixel units P in the pixel area 130 are used to display a frame. Driving components such as scan drivers or data drivers (not shown) can be arranged in the peripheral circuit area 120 . The light sensing area 140 is used to configure the light sensor 150 , and the light sensing area 140 can be designed at different positions on the TFT array substrate 100 according to different application levels.

[0076] For m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com