Ventilated wind pipe

A blower and a part of the technology, applied in the field of ventilation equipment, can solve the problems of time-consuming, laborious, difficult to operate, difficult to operate, etc., and achieve the effect of reducing manufacturing costs, tight joints, and not easy to leak air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

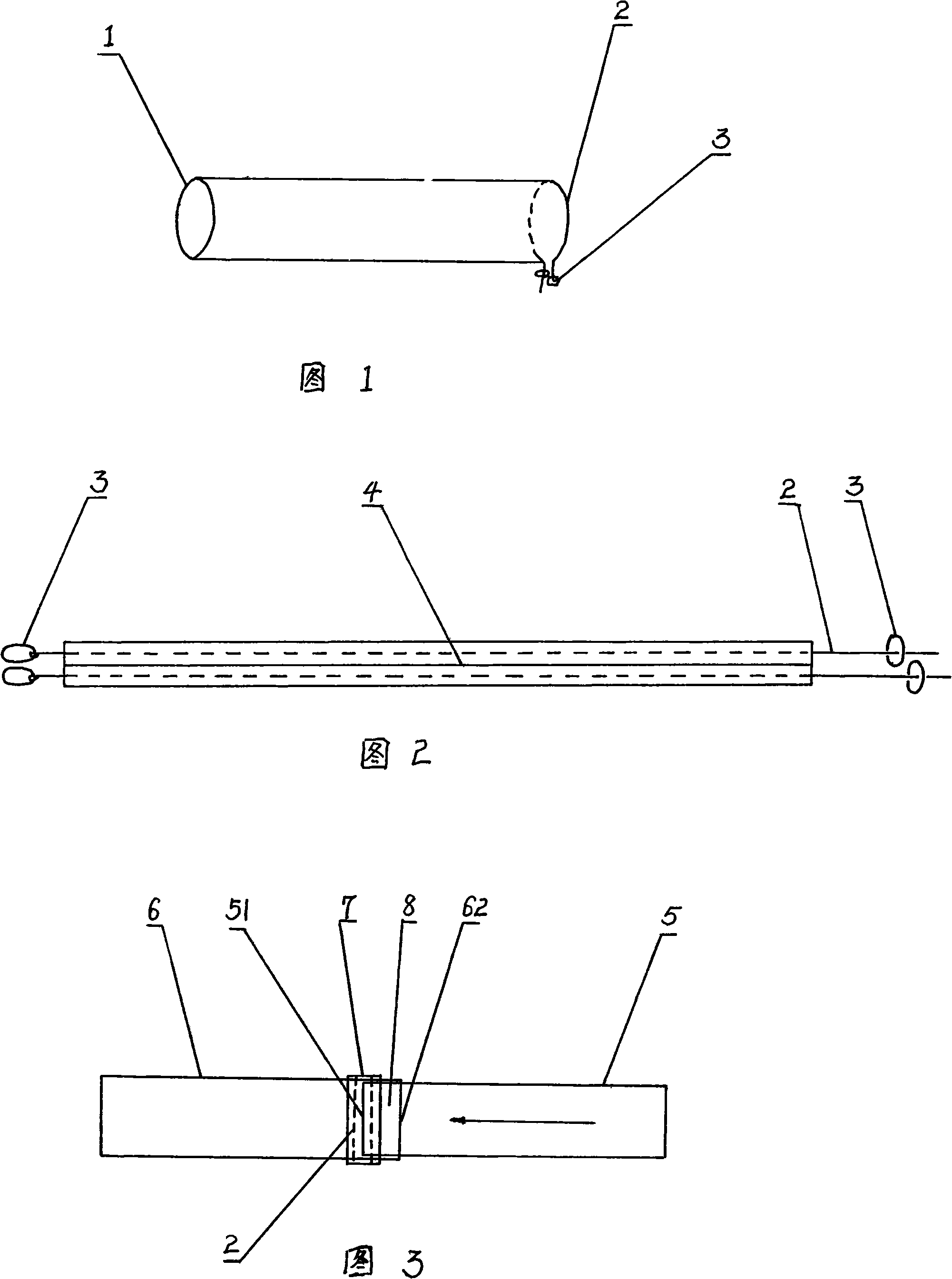

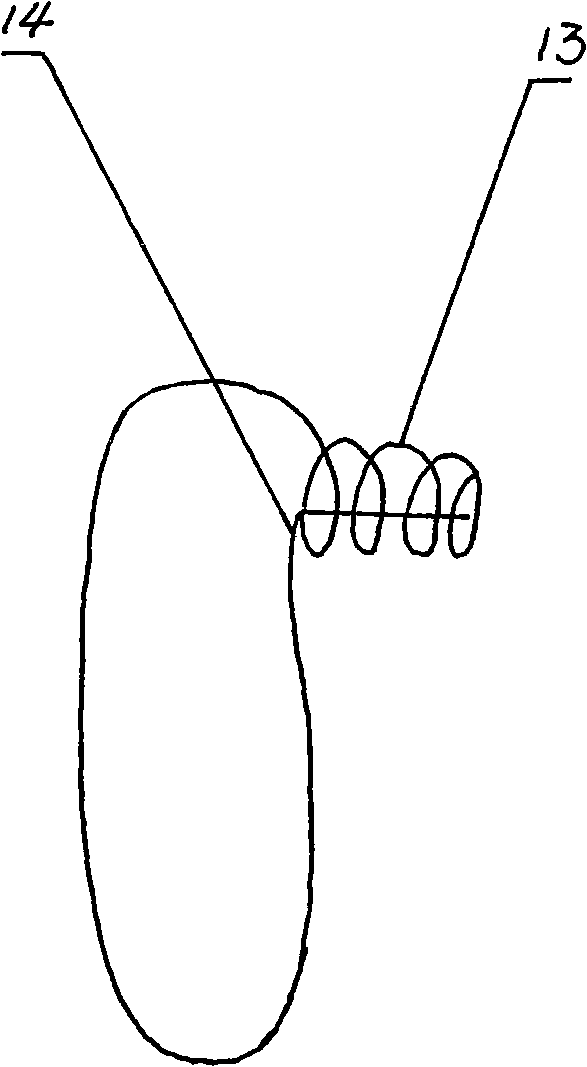

[0013] As shown in FIG. 1 , one end of the blower has a steel ring 1 , the other end is threaded with a rope 2 , and both ends of the rope 2 have locks 3 . As shown in Figure 2, there are two ropes 2 in the tight band. In order to prevent the ropes from being entangled with each other, the two ropes are separated. It can be isolated by two ropes, or other isolation methods can be used. As shown in Figure 3, the schematic diagram of the butt joint structure of the air duct, the arrow points to the air flow direction, 5 indicates the upper section of the air duct, 6 indicates the lower section of the air duct, and 7 indicates the tight band. The operation steps to connect the air cylinder are: 1. Put the rope end 62 of the lower air cylinder 6 over the steel ring end 51 of the upper air cylinder 5, tighten the rope of the rope end 62 of the air cylinder 6, and buckle the rope lock Buckle, but not too tight, so that the air duct is not blown open. Two, adjust air cylinder 6, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com