Shipping rudder system lighting and mounting method

A rudder system and lighting technology, which is applied to the lighting, boring and installation fields of the rudder system in ship construction, can solve the problems of affecting the construction cycle, wasting manpower and material resources, saving the time for cutting and returning to the internal factory for processing, and improving the Construction efficiency and the effect of ensuring the quality of ship construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

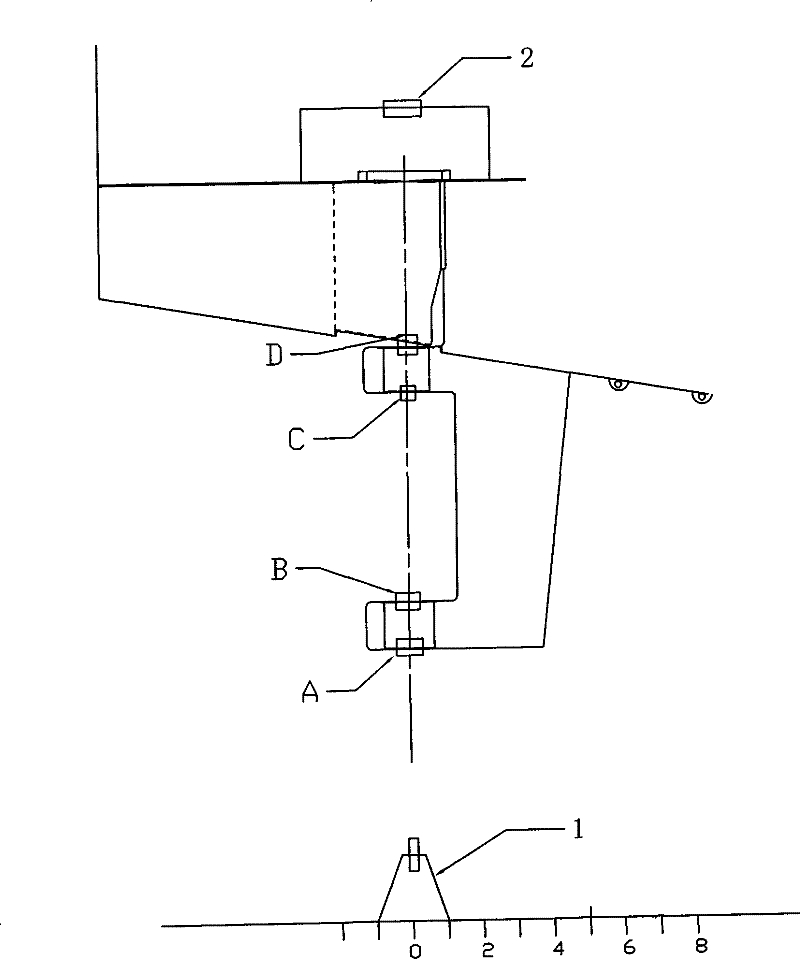

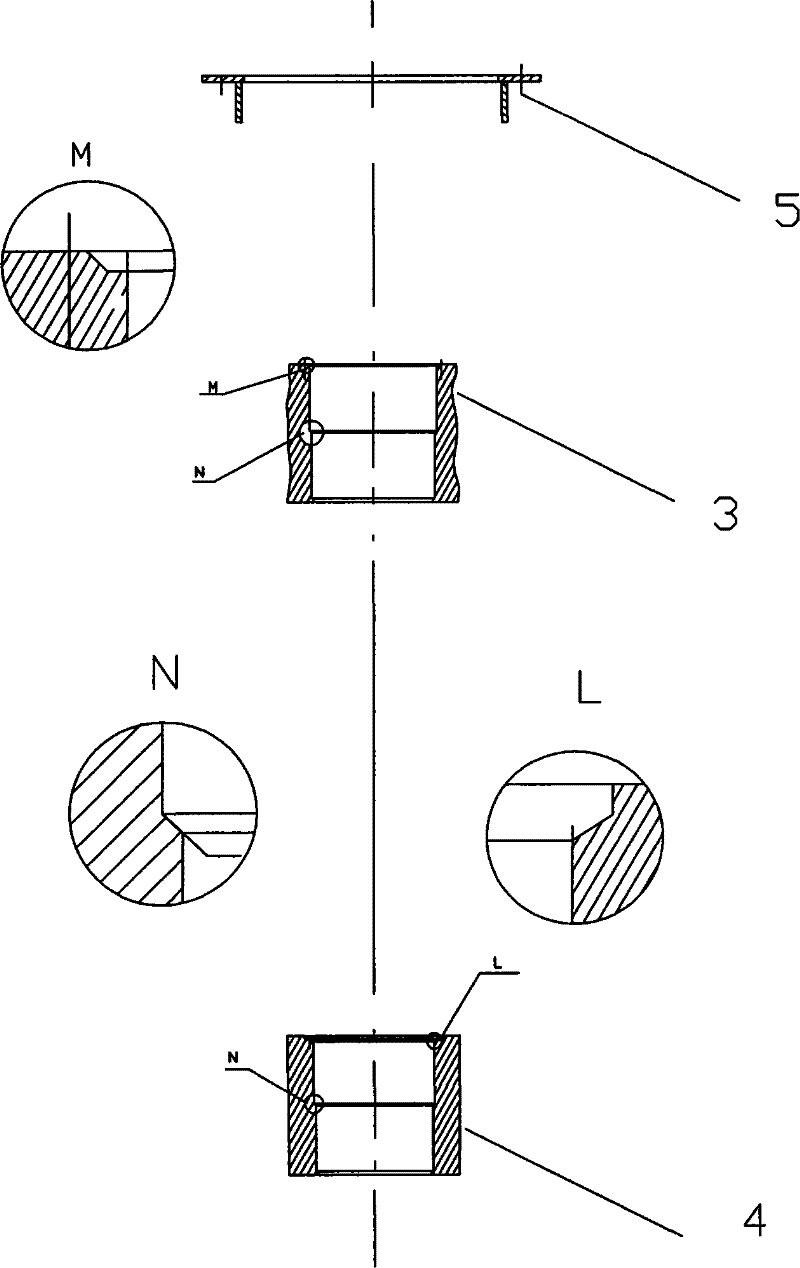

[0027] The rudder system illumination and installation process method of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0028] Taking the 75000 bulk carrier rudder system illumination and installation process as an example, the practical application of the method of the present invention is described in detail.

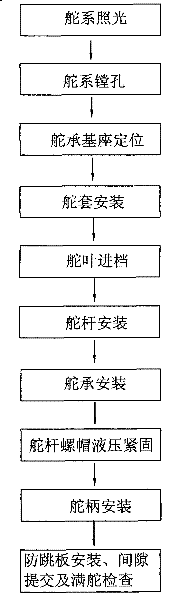

[0029] In the present embodiment, the rudder system illumination and installation process steps are as follows: image 3 shown, image 3 It is an operation flow chart of a method for lighting and installing a ship's rudder system according to the present invention:

[0030] The first step: the rudder system pulls the light.

[0031] The illuminator will place the illuminator at the 0th rib, just below the upper and lower rudder holes, and put a light adjustment frame and a bright line target on the end face of the upper rudder hole and the end face of the lower rudder hole to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com