Equipment for mixing catalyst

A technology of mixing equipment and catalyst, which is used in the field of fluidized catalytic cracking of hydrocarbon raw materials, can solve the problems of complex structure, inability to mix catalysts uniformly, and large repression effect, and achieves the effect of no pressure fluctuation, stable operation, and elimination of repression effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

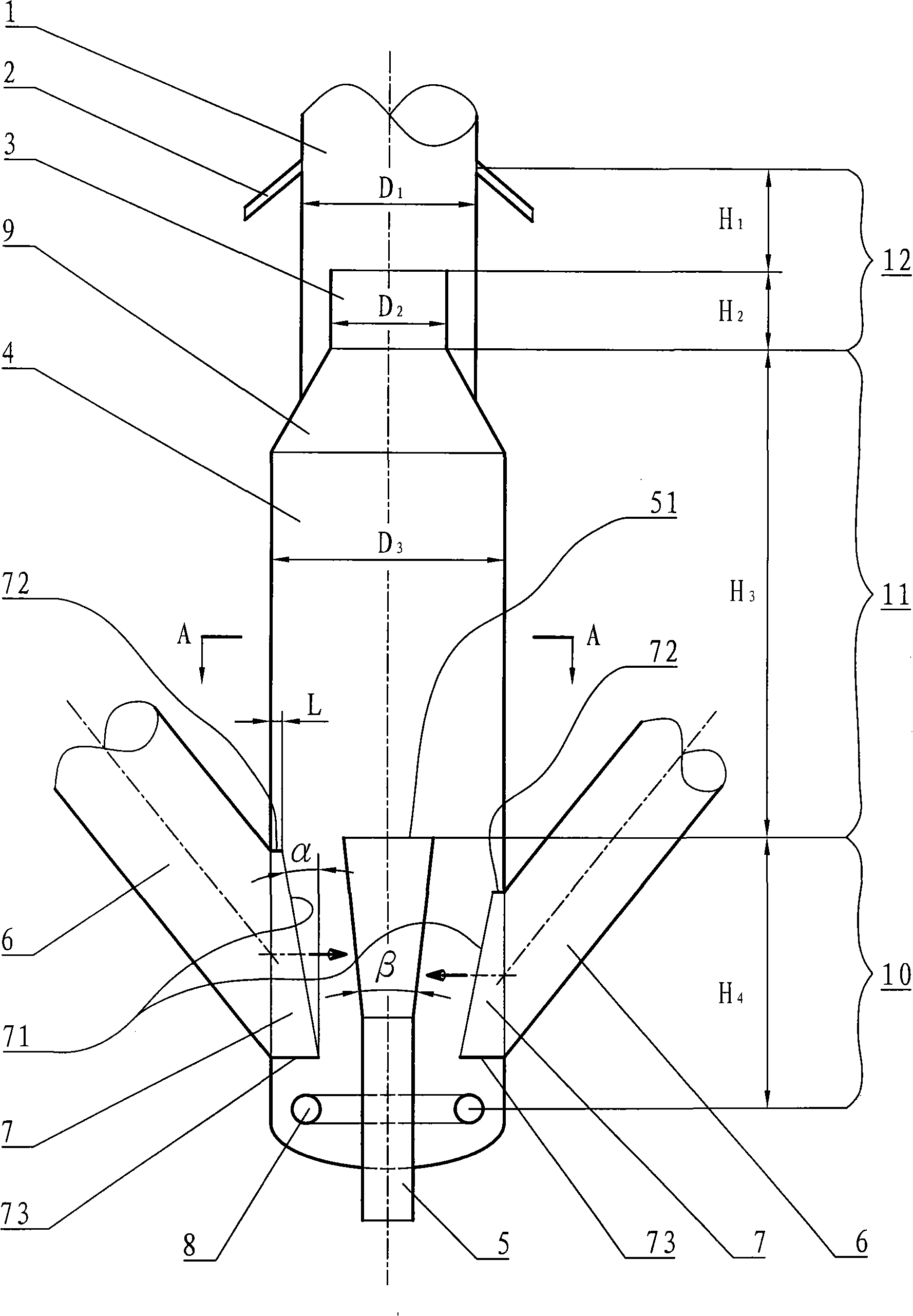

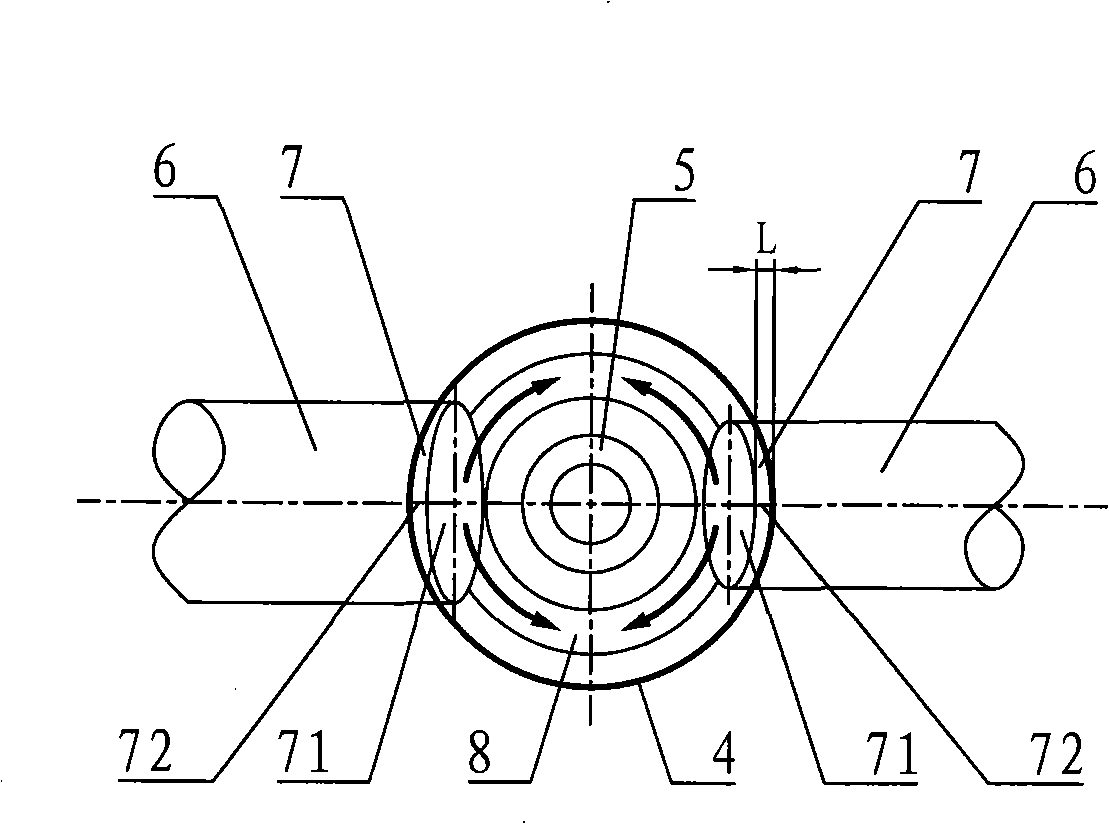

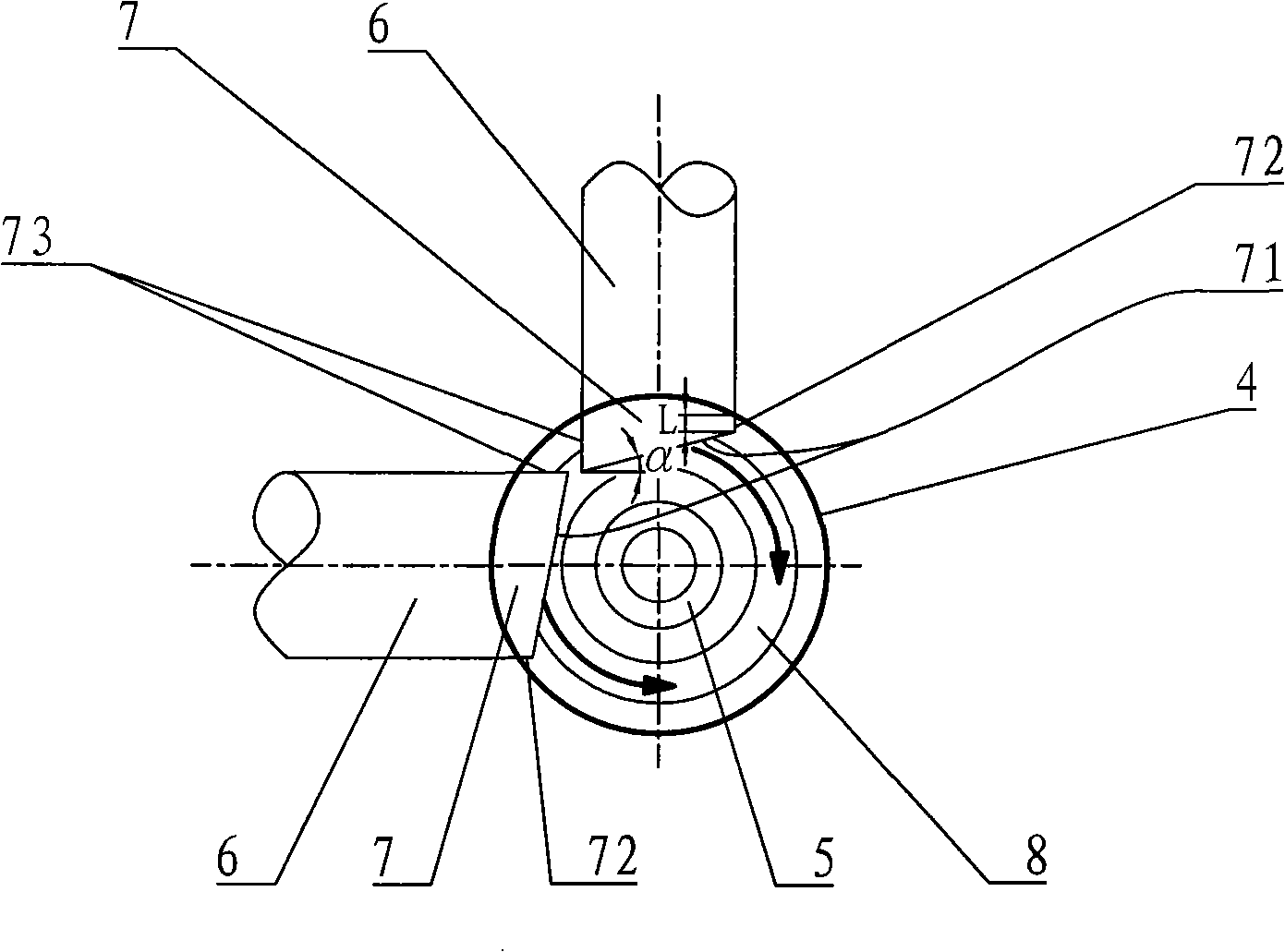

[0017] see figure 1 , figure 2 A catalyst mixing apparatus of the present invention is shown. The catalyst mixing device comprises a cylindrical barrel 4 . The top of the cylinder body 4 is provided with a conical section 9, and the bottom is provided with a head; the head is usually a hemispherical head. The conical section 9 is in the shape of a truncated conical tube and is connected to the bottom of the riser reactor 1 . There are at least two feeding inclined pipes 6 connected to the lower part of the cylinder body 4 . The inclined feeding pipes 6 are arranged around the circumferential direction of the cylinder body 4, and the number thereof is the same as the number of strands of catalysts with different properties to be mixed, the most common being two or three; figure 1 , figure 2 The catalyst mixing device shown is connected to two discharge ramps 6 .

[0018]A draft tube 7 is arranged horizontally at the interface between each feeding inclined tube 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com