Multi-force output air gap monostable permanent magnet control mechanism with manual emergency switching mechanism

A technology of opening mechanism and permanent magnet operation, applied in the direction of contact drive mechanism, contact operating mechanism, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below in conjunction with the accompanying drawings.

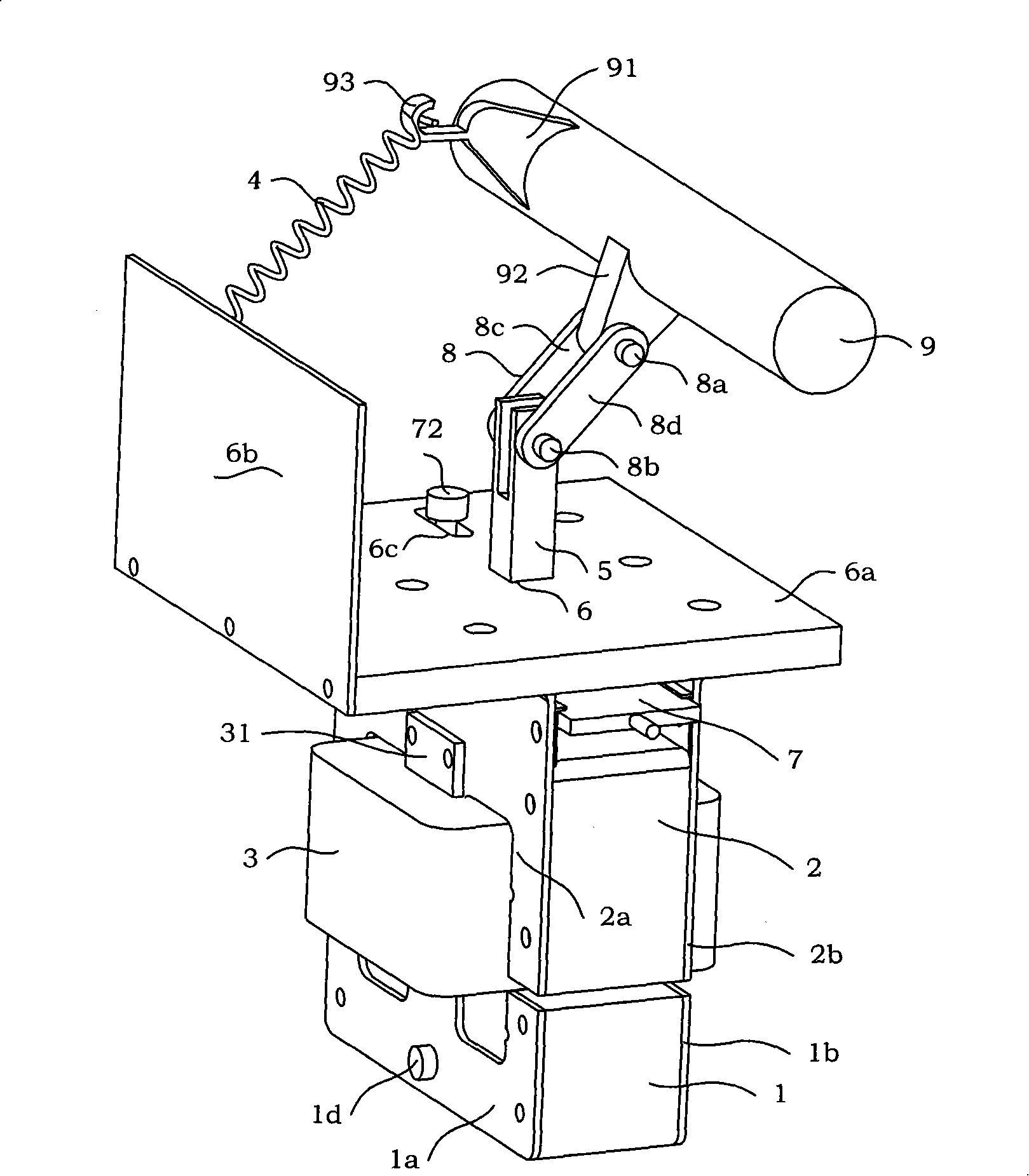

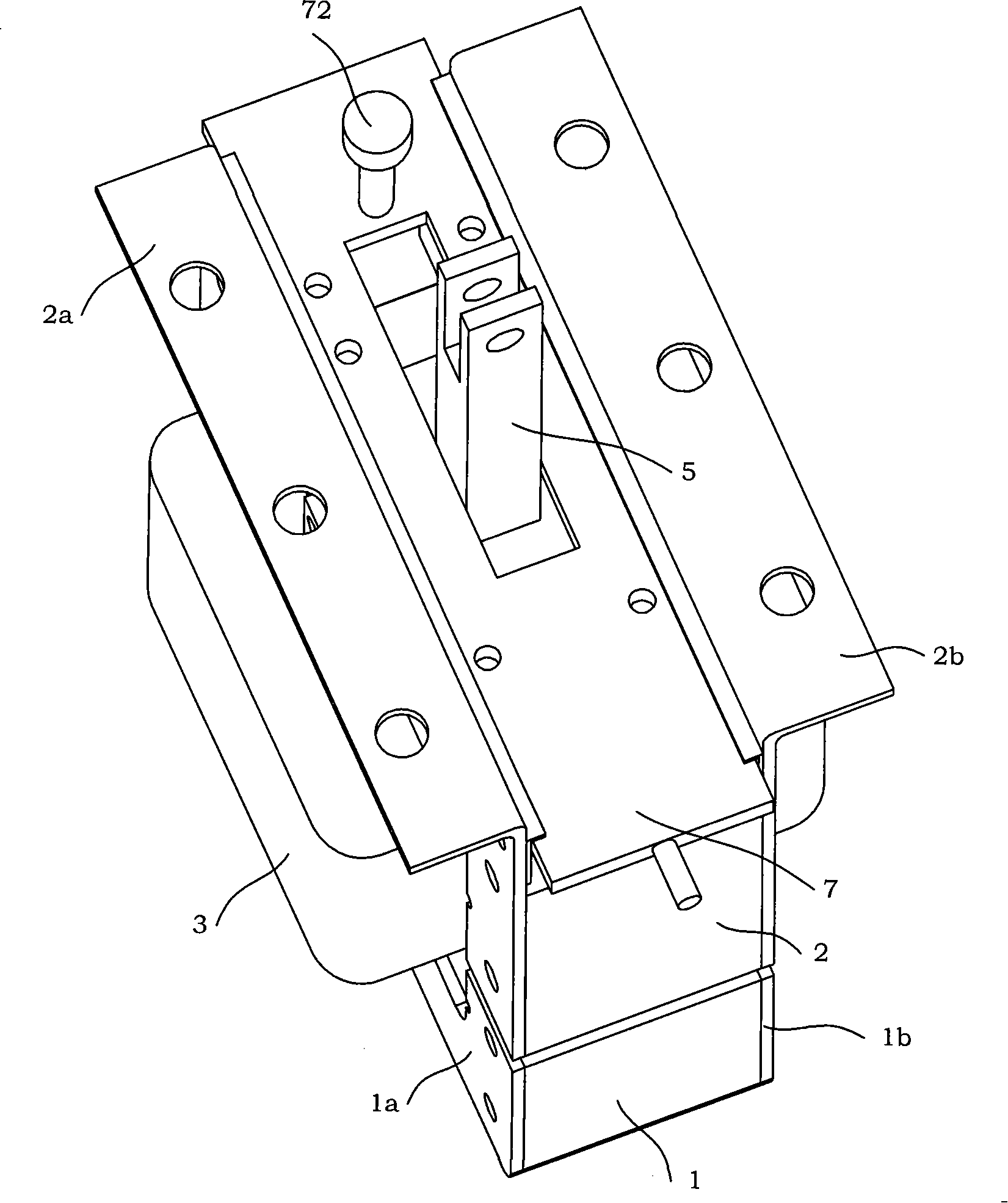

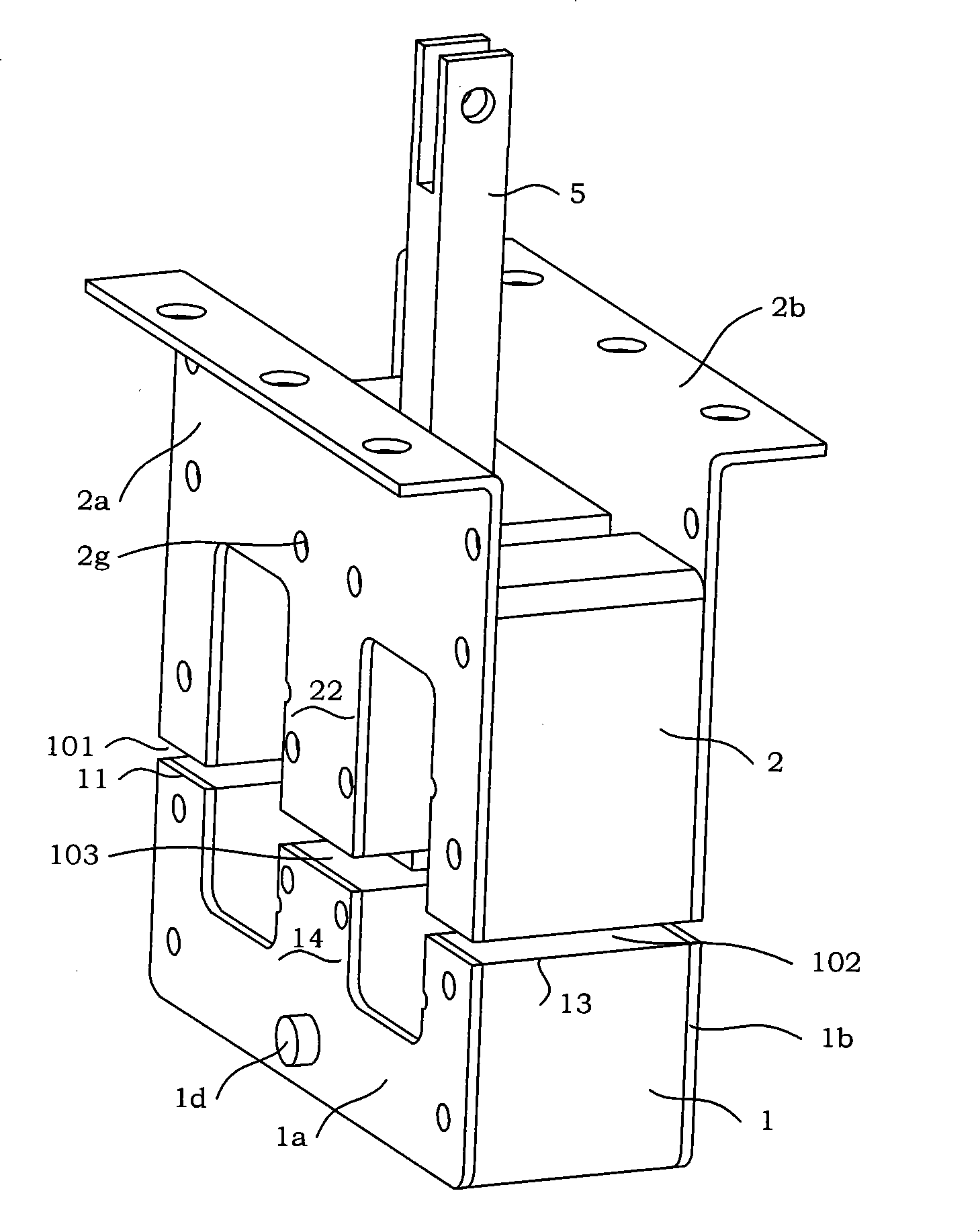

[0071] see figure 1 , Figure 1A , Figure 1B As shown, the present invention is a multi-force air gap monostable permanent magnet operating mechanism with a manual emergency opening mechanism, including a moving iron core 1, a static iron core 2, an opening and closing coil 3, an opening spring 4, Transmission rod 5, support plate 6a, fixed plate 6b, emergency opening mechanism 7, connector 8, rotating shaft 9, A permanent magnet 10, B permanent magnet 11; the moving iron core 1 is placed under the static iron core 2, and the moving iron core 1 and There are three air gaps (A air gap 101, C air gap 103, B air gap 102) between the static iron cores 2; On the A boss 2c of the C pressing piece 2a and the B boss 2e of the D pressing piece 2b; one end of the opening spring 4 is installed on the fixed plate 6b, and the other end of the opening spring 4 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com