Side frame for large-scale box

A box, large-scale technology, applied in the direction of large containers, superstructures, containers, etc., can solve the problems of goods and sidewall steps rubbing or even clamping, sidewall structure and goods damage, etc., to improve connection reliability, reduce Shear stress, the effect of increasing the load space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

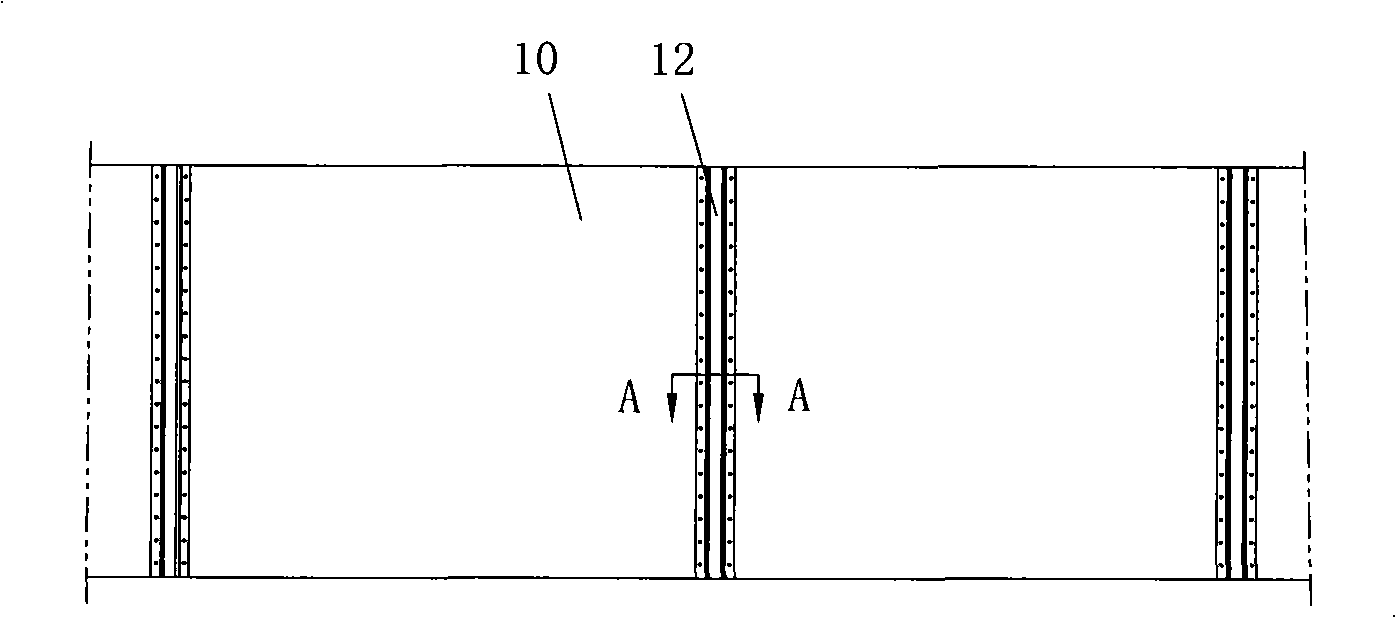

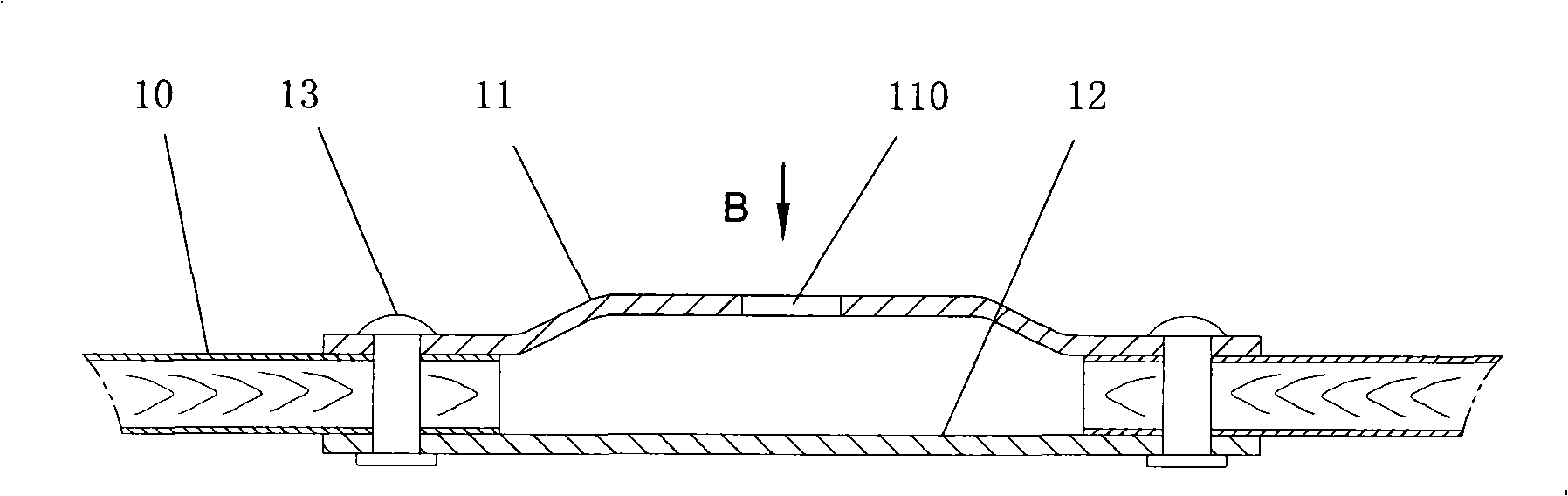

[0028] The side wall for a large box of the present invention includes a plurality of frameless side panels 20 spliced with each other and a splicing structure connecting the spliced ends of two adjacent frameless side panels 20 . Such as Figure 4 , Figure 5 As shown, the splicing structure includes an inner connecting piece 21 located in the box on both sides of the splicing ends of two adjacent frameless side plates 20, an outer connecting piece 22 located outside the box and connecting the inner connecting piece 21, the outer connecting piece 22 and the The rivet 23 at the splicing end of the frameless side plate 20 . The cross-section of the overlapping part of the inner connector 21 and the splicing end of the frameless side plate 20 is corrugated, and the cross-sectional shape of the contact surface of the overlapping part of the splicing end of the frameless side plate 20 and the inner connector 21 adopts the overlapping part of the inner connector 21 The corrug...

Embodiment 2

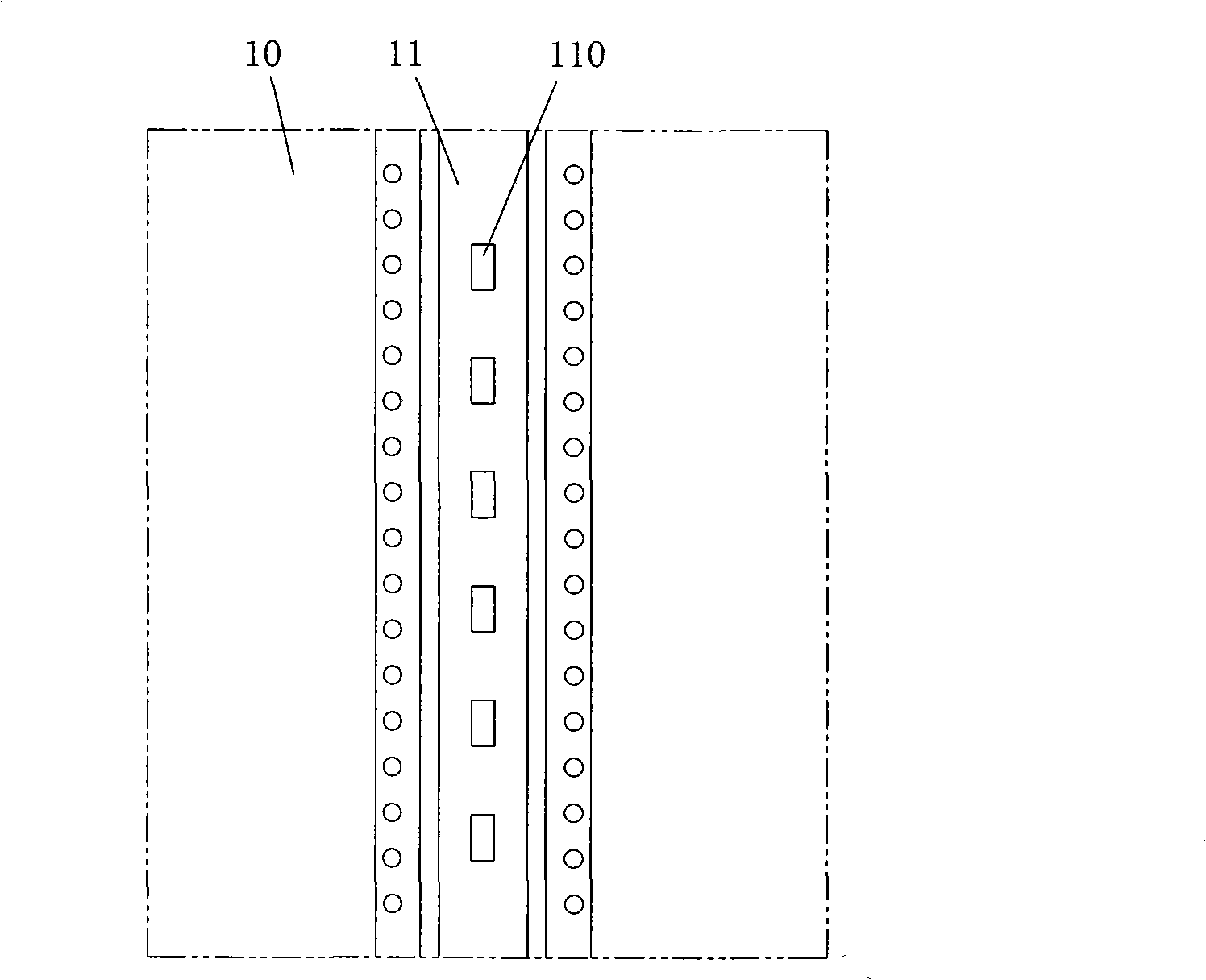

[0032] Such as Figure 6 , Figure 7 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that the part of the inner connecting member 31 corresponding to the spaced position adopts a straight shape, and the straight part of the inner connecting member 31 is provided with a through hole 310 . In other embodiments, the straight portion of the inner connecting member 31 may not be provided with the through hole 310 .

Embodiment 3

[0034] Such as Figure 8 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that the outer connecting member 42 adopts a connecting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com