High speed permanent magnet motor rotor

A technology for permanent magnet motors and rotors, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., and can solve the problems of irreversible high-temperature loss of magnetism, large eddy current loss, and temperature rise of solid rotors on the permanent magnet on the rotor side.

Active Publication Date: 2010-12-01

JING JIN ELECTRIC TECH CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problem that the existing high-speed permanent magnet motor has a large eddy current loss when a protective sleeve is added to the rotor side, the temperature rise of the solid rotor is too high, and the permanent magnet on the rotor side produces irreversible high-temperature demagnetization. The present invention provides a high-speed permanent magnet motor. magneto rotor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

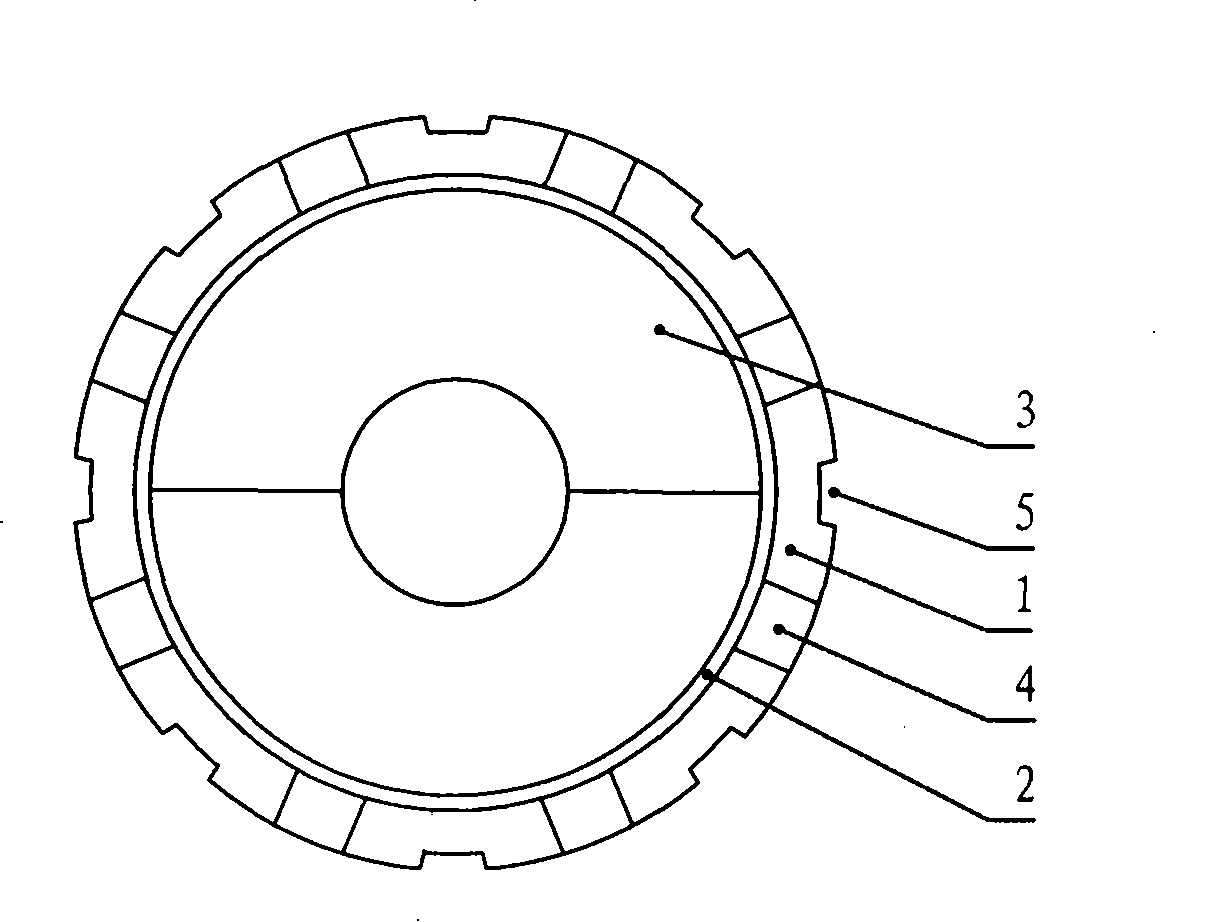

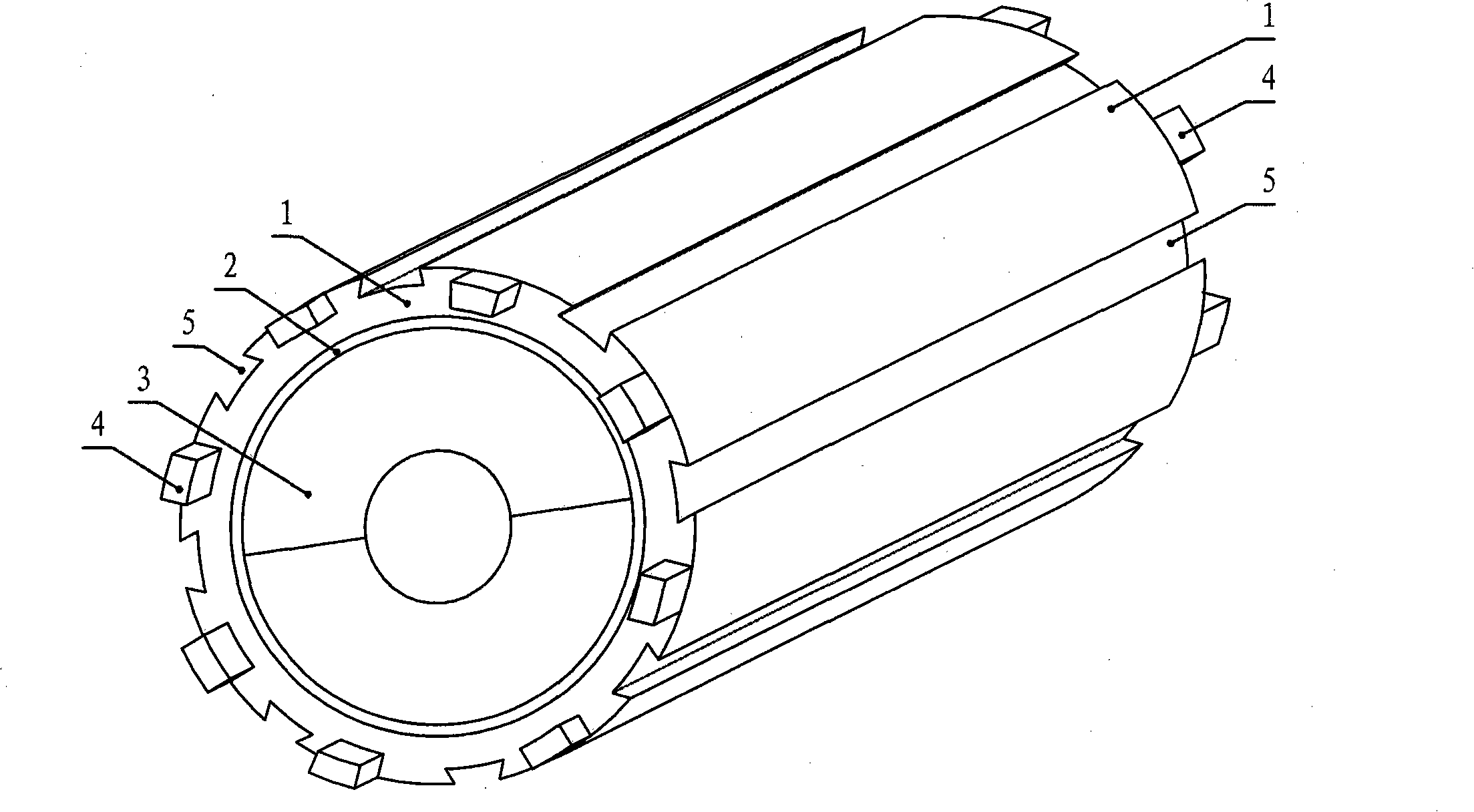

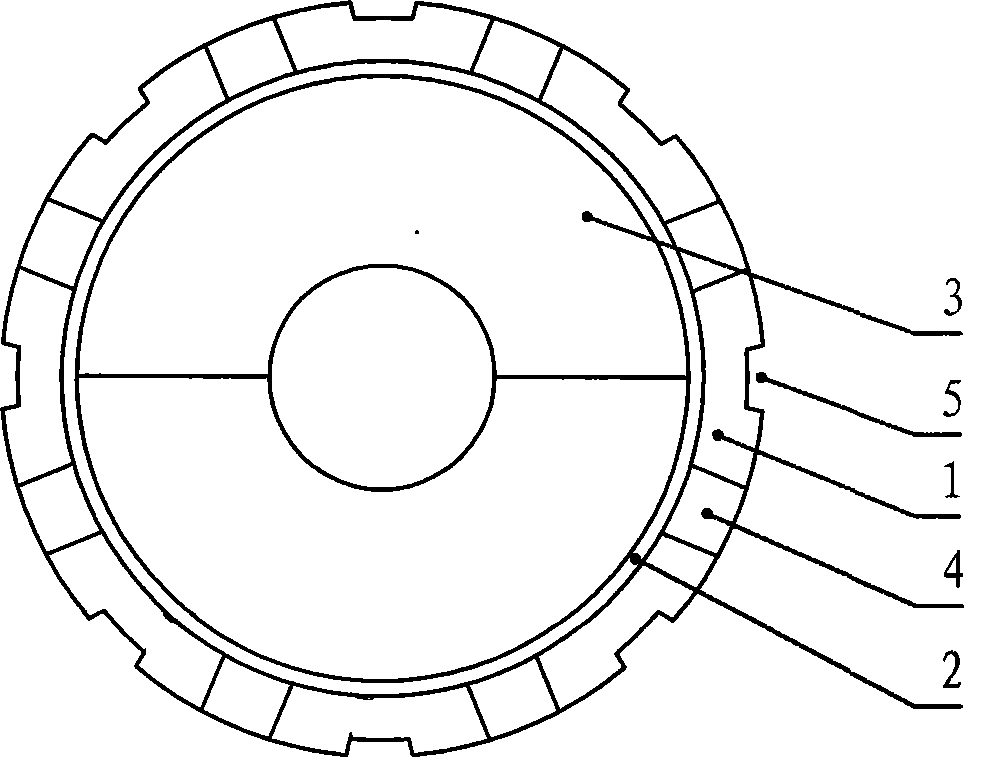

The invention relates to a high-speed permanent magnetic motor rotor, belonging to the field of motor. The high-speed permanent magnetic motor rotor solves the problems that the eddy current loss is comparatively large which leads to the temperature increment of the solid rotor to be excessively high easily and the permanent magnet beside the rotor to generate irreversible high-temperature loss of field when a protection sleeve is added beside the rotor in the existing high-speed permanent magnetic motor. The high-speed permanent magnetic motor rotor comprises a rotor protection sleeve (1), apermanent magnet (3), and an insulation layer (2) which is arranged between the rotor protection sleeve (1) and the permanent magnet (3). A plurality of concave troughs (5) which are parallel to the central axis line of the rotor are uniformly distributed on the rotor protection sleeve (1) along the circumference of the external surface of the rotor protection sleeve (1); two end surfaces of the rotor protection sleeve (1) are uniformly and fixedly provided with a plurality of bulges (4). The high-speed motor rotor of the invention is applicable to the existing high-speed permanent motors.

Description

High speed permanent magnet motor rotor technical field The invention relates to a high-speed permanent magnet motor rotor, which belongs to the field of motors. Background technique High-speed permanent magnet motors not only have the characteristics of high speed, high power density, high material utilization, fast dynamic response and high transmission system efficiency of ordinary high-speed motors, but also have the advantages of high efficiency and high power factor. Therefore, high-speed permanent magnet motors have good application prospects in centrifugal compressors of air conditioners or refrigerators, energy storage flywheels, textiles, high-speed grinders, hybrid vehicles, aviation, and ships. Especially in the distributed power generation system, the high-speed generator driven by the gas turbine is small in size and has high mobility. It can be used as a backup power source for hospitals, hotels and other important facilities, and can also be used as an inde...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02K1/27

Inventor 李伟力沈稼丰张晓晨霍菲阳谭天江

Owner JING JIN ELECTRIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com