Method for preparing single crystal zinc blende nano-wire

A technology of nanowires and zinc sulfide, applied in the field of preparation of zinc sulfide nanowires, can solve the problems affecting the physical properties of ZnS nanostructures and high synthesis temperature, and achieve the effects of easy large-scale production, easy availability of raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Ultrasonic cleaning the blank silicon wafer in alcohol and acetone respectively;

[0019] 2. In the tube furnace, feed a flow rate of argon and hydrogen gas mixture (the volume ratio of hydrogen and argon is 10: 100);

[0020] 3. Put the ZnS powder in a quartz boat as an evaporation source, and put it in a tube furnace together with the boat. The cleaned silicon wafer is also placed in the furnace, 30mm away from the evaporation source, wherein the evaporation source is placed upstream of the incoming airflow, and the silicon wafer is placed downstream of the airflow;

[0021] 4. Heat up the temperature of the tube furnace to 900°C, and the holding time is 100min. The pressure in the furnace is 0.015MPa. After the temperature of the furnace dropped to room temperature, the silicon wafer was taken out, and a layer of ZnS nanowire white film was deposited on the silicon wafer.

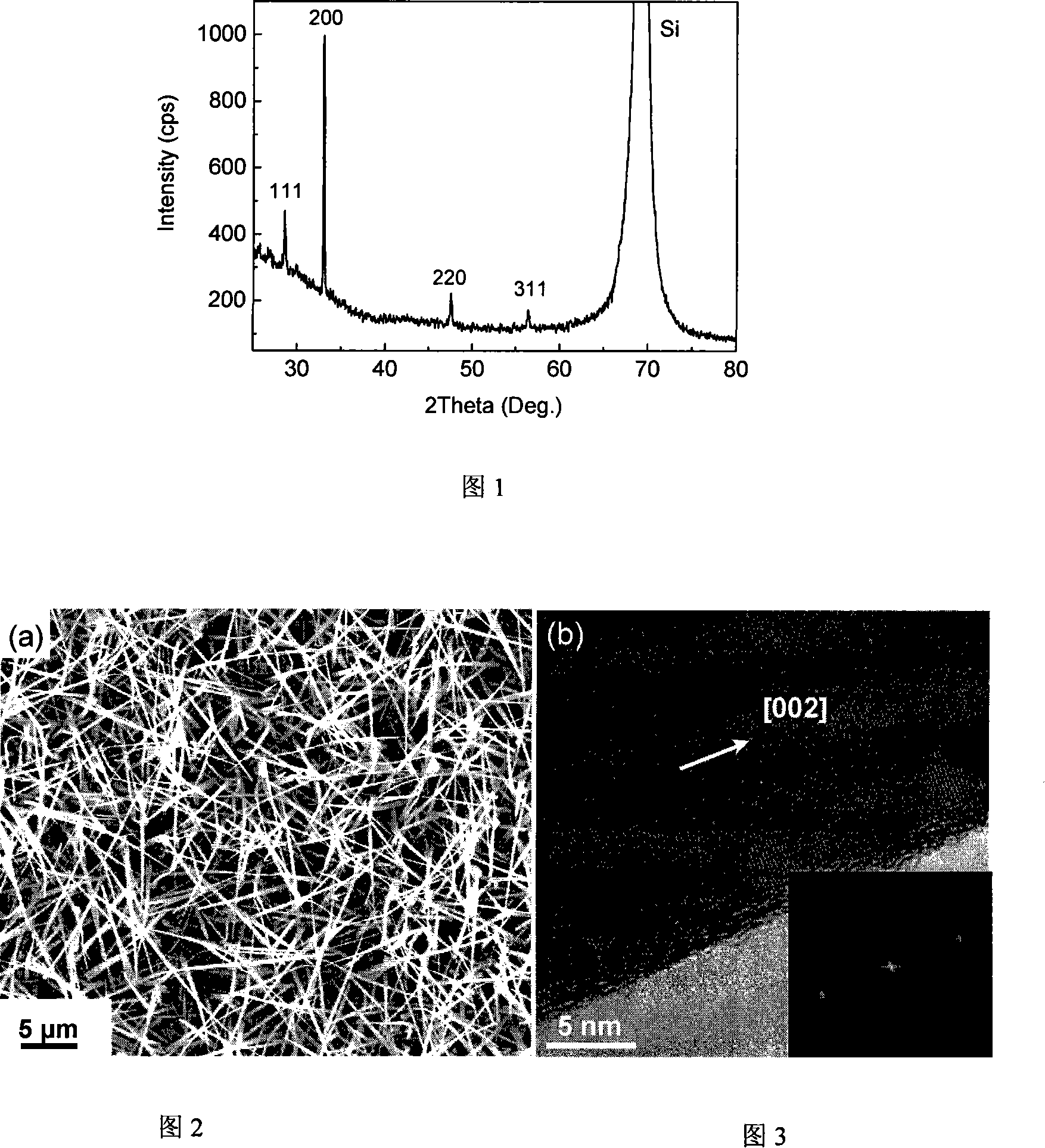

[0022] figure 1 It is the X-ray diffraction pattern of the product, and all the diffrac...

Embodiment 2

[0024] 1. Ultrasonic cleaning the blank silicon wafer in alcohol and acetone respectively;

[0025] 2. In the tube furnace, feed a flow rate into a mixture of argon and hydrogen (the volume ratio of hydrogen and argon is 13: 100);

[0026] 3. Put the ZnS powder in a quartz boat as an evaporation source, and put it in a tube furnace together with the boat. The cleaned silicon wafer is also placed in the furnace, 25mm away from the evaporation source, wherein the evaporation source is placed upstream of the incoming airflow, and the silicon wafer is placed downstream of the airflow;

[0027] 4. The temperature of the tube furnace was raised to 890° C., and the holding time was 120 minutes. The pressure in the furnace is 0.03MPa. After the temperature of the furnace dropped to room temperature, the silicon wafer was taken out, and a layer of ZnS nanowire white film was deposited on the silicon wafer.

Embodiment 3

[0029] 1. Ultrasonic cleaning the blank silicon wafer in alcohol and acetone respectively;

[0030] 2. In the tube furnace, the mixed gas of argon and hydrogen (the volume ratio of hydrogen and argon is 8: 100) is fed into the flow rate of 108ml / min;

[0031] 3. Put the ZnS powder in a quartz boat as an evaporation source, and put it in a tube furnace together with the boat. The cleaned silicon wafer is also placed in the furnace, 28mm away from the evaporation source, wherein the evaporation source is placed upstream of the incoming airflow, and the silicon wafer is placed downstream of the airflow;

[0032] 4. The temperature of the tube furnace was raised to 910°C, and the holding time was 80 minutes. The pressure in the furnace is 0.025MPa. After the temperature of the furnace dropped to room temperature, the silicon wafer was taken out, and a layer of ZnS nanowire white film was deposited on the silicon wafer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com