Lubricant composition for internal combustion engine

一种润滑油组合物、内燃机的技术,应用在润滑组合物、石油工业、基料等方向,能够解决油消耗增大、起不到稠化内燃机油的作用等问题,达到蒸发性小、氧化稳定性优异、低温流动性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] Next, although an Example demonstrates this invention more concretely, this invention is not limited to these examples.

[0150] The properties and performances of the lubricating oil compositions obtained in each example were determined by the following methods.

[0151] (1) Kinematic viscosity

[0152] Based on JIS K2283, the kinematic viscosity at 40 degreeC and 100 degreeC was measured.

[0153] (2) Viscosity index

[0154] Measured according to JIS K2283.

[0155] (3) acid value

[0156] Measured according to JIS K2501.

[0157] (4) Base value

[0158] Measured according to JIS K2501 (hydrochloric acid method).

[0159] (5) CCS viscosity

[0160] The viscosity at -35 degreeC was measured according to JISK2010.

[0161] (6) NOACK evaporation test

[0162] Measured under the conditions of 250° C. and 1 hour according to the standard PI-5S-41-93 of the Petroleum Institute.

[0163] (7) ISOT oxidation stability test

[0164] Based on the oxidation stability ...

preparation example 1

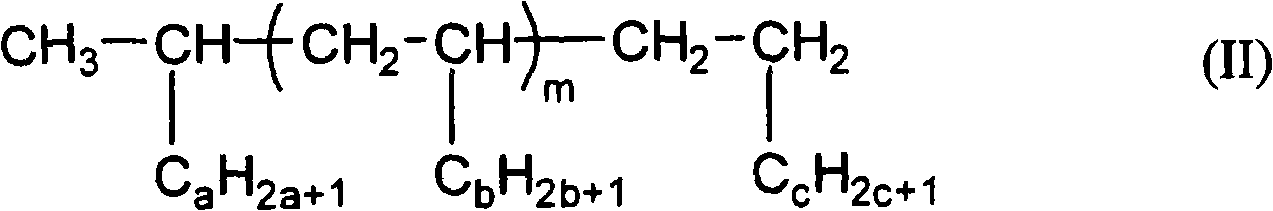

[0165] Preparation Example 1 The preparation of α-olefin oligomer hydrogenated product with 30 carbon atoms

[0166] (a) Oligomerization of decene

[0167]Into a three-necked flask with an internal volume of 5 L, 4 L (21.4 moles) of decene monomer (manufactured by Idemitsu Kosan Co., Ltd.: Linialen 10) was added under an inert gas flow, and dicyclopentadiene dissolved in toluene was further added. zirconium dichloride (complex mass: 1168 mg: 4 mmol) and methylaluminoxane (in terms of Al: 40 mmol) similarly dissolved in toluene. These mixtures were kept at 40° C. and stirred for 20 hours, and then 20 ml of methanol was added to stop the oligomerization reaction. Then, the reaction mixture was taken out from the autoclave, 4 L of a 5 mol / L aqueous sodium hydroxide solution was added thereto, and after forced stirring at room temperature for 4 hours, a liquid separation operation was performed. The upper organic layer was taken out, and unreacted decene and by-product decene is...

Embodiment 1~4 and comparative example 1

[0171] The base oils and additives shown in Table 1 were mixed at the ratios shown in Table 1 to prepare lubricating oil compositions for internal combustion engines, and their properties and performance were obtained. The results are shown in Table 1.

[0172] [Table 1]

[0173]

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com