Fuse and assembly method thereof

An assembly method and technology of fuses, which are applied in emergency protection devices, electrical components, circuits, etc., can solve problems such as easy damage or failure of fuses, poor contact between sealing caps and fuses, and easy pressure breakage at both ends of fuses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

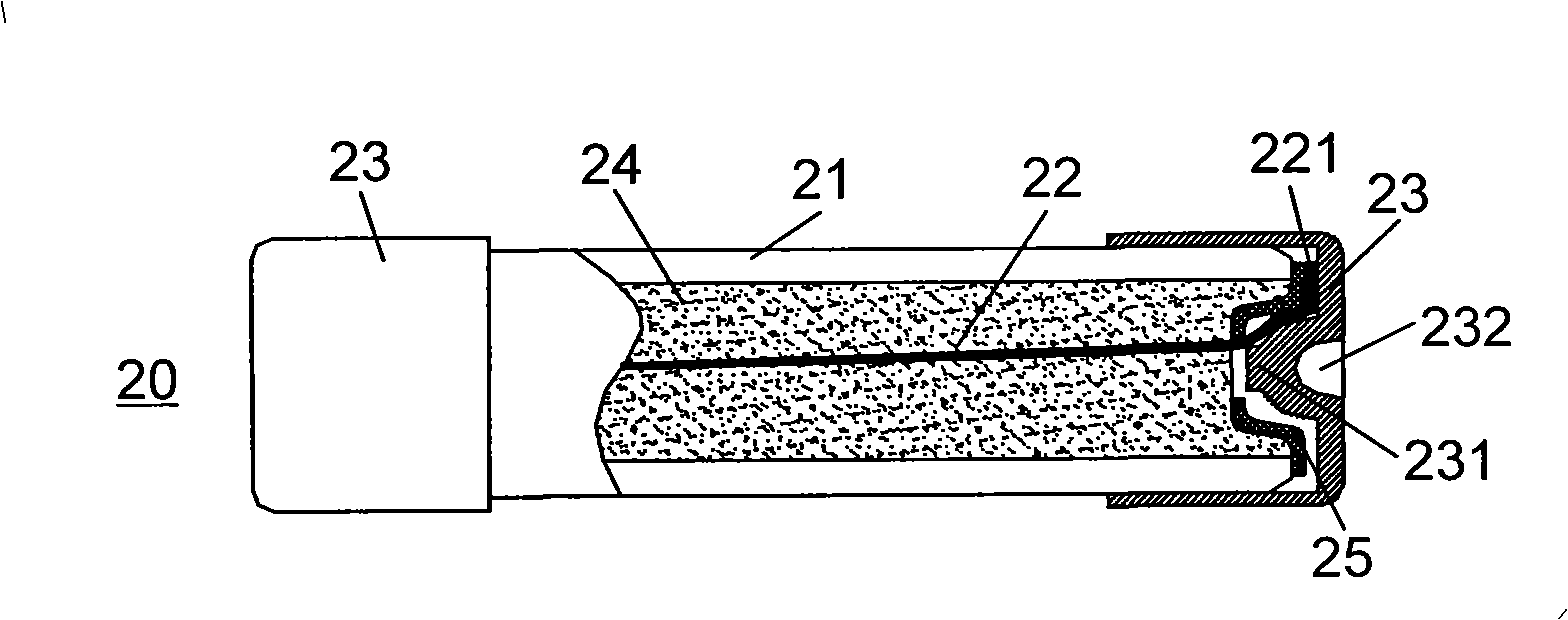

[0032] This embodiment is a large size fuse.

[0033] see figure 2 As shown, the size of the diameter and length of the fuse 20 of the present invention is 6.3MM×25.4MM. The fuse 20 includes a body 21, a fuse 22 and a sealing and fixing part. The body 21 is a tubular structure with openings at both ends. Made of materials, the inside of the body 21 is filled with an appropriate amount of quartz sand 24 of uniform thickness; the fuse 22 extends into the inside of the body 21, and the two ends pass through the body 21 and out of the body 21; the sealing and fixing parts further include a fixing gasket 25 and a sealing cap 23. The fixed gasket 25 is arranged at both ends of the body 21 and is offset against the two ends of the body 21; the sealing cap 23 is set at both ends of the body 21, respectively offset with the fixed gasket 25 and the fuse 22, and connected and fixed with the two ends of the body 21. The two ends of the fuse 22 pass through the fixed washer 25 respective...

Embodiment 2

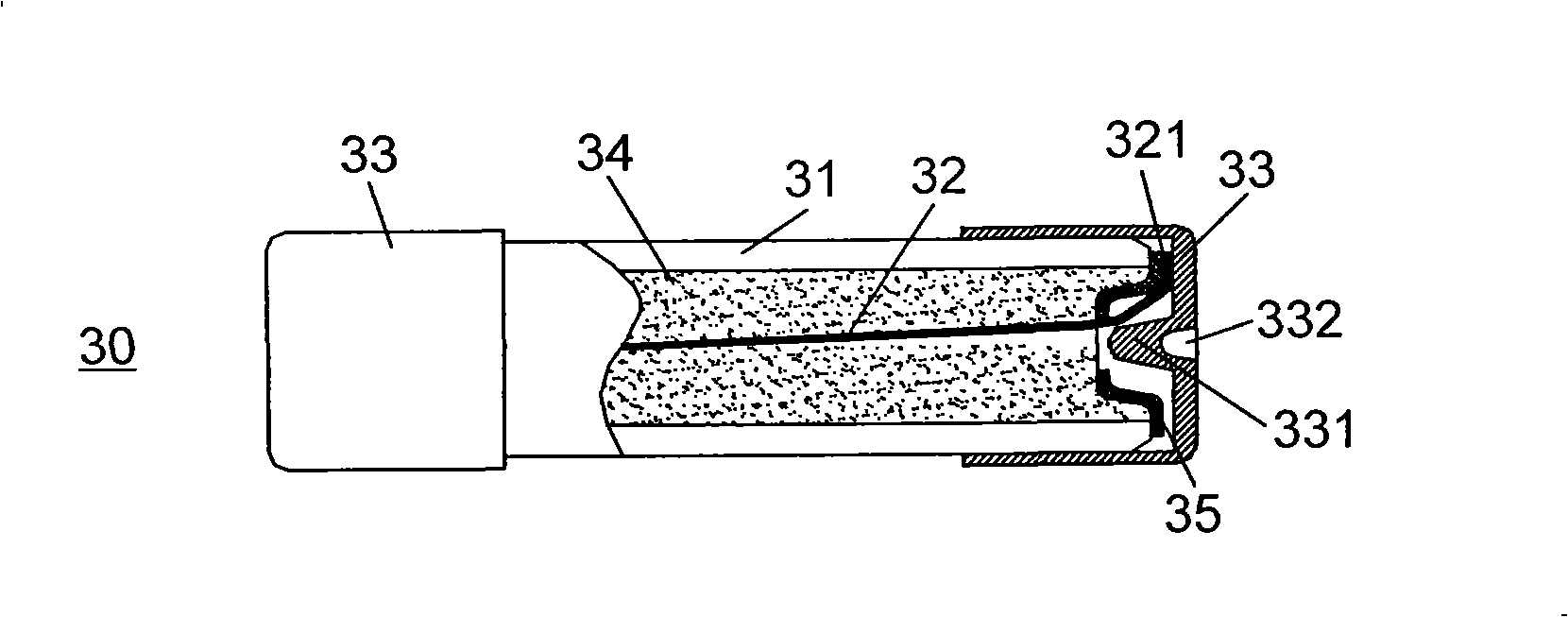

[0035] This embodiment is a small size fuse.

[0036] see image 3As shown, the diameter and length of the fuse 30 of the present invention are 5MM×20MM. The fuse 30 includes a body 31, a fuse 32 and a sealing and fixing part. The body 31 is a tubular structure with openings at both ends and is made of insulating material. , the inside of the body 31 is filled with an appropriate amount of quartz sand 34 of uniform thickness; the fuse 32 extends into the inside of the body 31, and the two ends pass through the body 31 and pass through the fixing gasket 35; the sealing and fixing parts further include a fixing gasket 35 and a sealing cap 33 , the fixed gasket 35 is arranged at the two ends of the body 31, and is against the two ends of the body 31; The two ends of the fuse 32 pass through the fixed washer 35 respectively, and are bent radially along one end of the fixed washer 35. The bent end 321 of the fuse 32 is in contact with the surface of one end of the fixed washer 35,...

Embodiment 3

[0038] see Figure 4 As shown, the steps of the assembly method of the fuse of the present invention are as follows: the first step is to select the body of the tubular structure, and install it on one end of the body with a fixed washer; the second step is to extend one end of the fuse into the body and pass through The fixed gasket set at one end of the body is then bent; the third step is to select a sealing cap sleeve on one end of the body and seal it with one end of the body, and use pressure to press the inner wall of the sealing end of the sealing cap against the surface of the fixed gasket and clamp the fuse and make the protruding part on the inner wall of the sealing end of the sealing cap fit with the fixed gasket; the fourth step is to pour an appropriate amount of quartz sand with uniform thickness into the body; finally, use the same method to seal the other end of the body fixed. The specific steps of the second step are: firstly insert one end of the fuse int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com