Super large workspace spherical face hinge possessing bias output

A spherical hinge and working space technology, which is applied to manufacturing tools, manipulators, pivot connections, etc., can solve the problems of large working space and small swing range of the output rod of spherical hinges, and achieve the effect of improving sports performance and flexible sports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

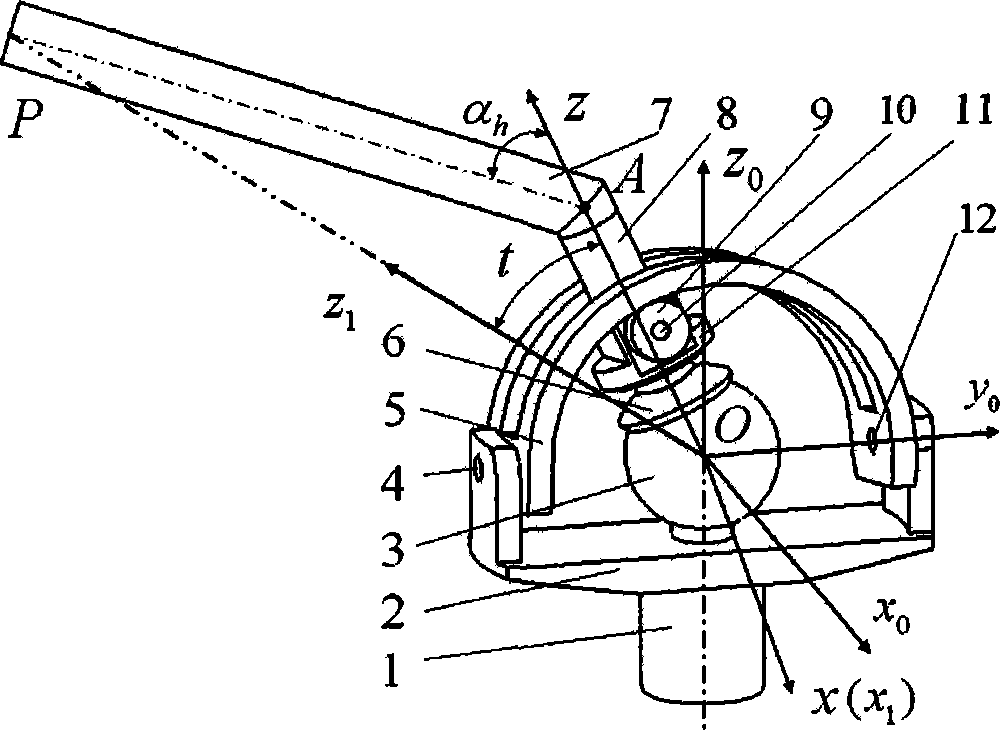

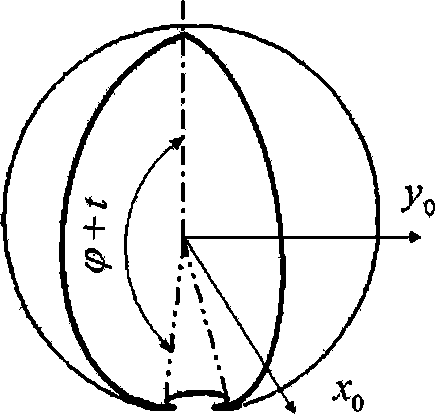

[0041] figure 1 is the first disclosed embodiment of the invention, which consists of a spherical hinge with a large working space and an offset output unit. The bias output unit includes a bias output rod 7 and a straight output rod 8; the spherical hinge with a large working space includes a support unit, an output unit and a spherical sub-unit, and the support unit includes a lower support rod 1, two ears The bracket 2, the U-shaped shift fork 5 and the double-ear bracket 2 constitute pins (4, 12) that are rotationally connected; the output unit includes a straight output rod 8, support rollers (9, 9'), support pins (10, 10') and a rotating bracket 11; Among them, the offset output rod 7 and the straight output rod 8 are fixedly connected at the intersection point A of the axes of the two rods. The overall output rod is in the shape of a bend. Point A is located outside the U-shaped shift fork of the spherical hinge. The angle between the axes of the two shafts is alpha ...

Embodiment 2

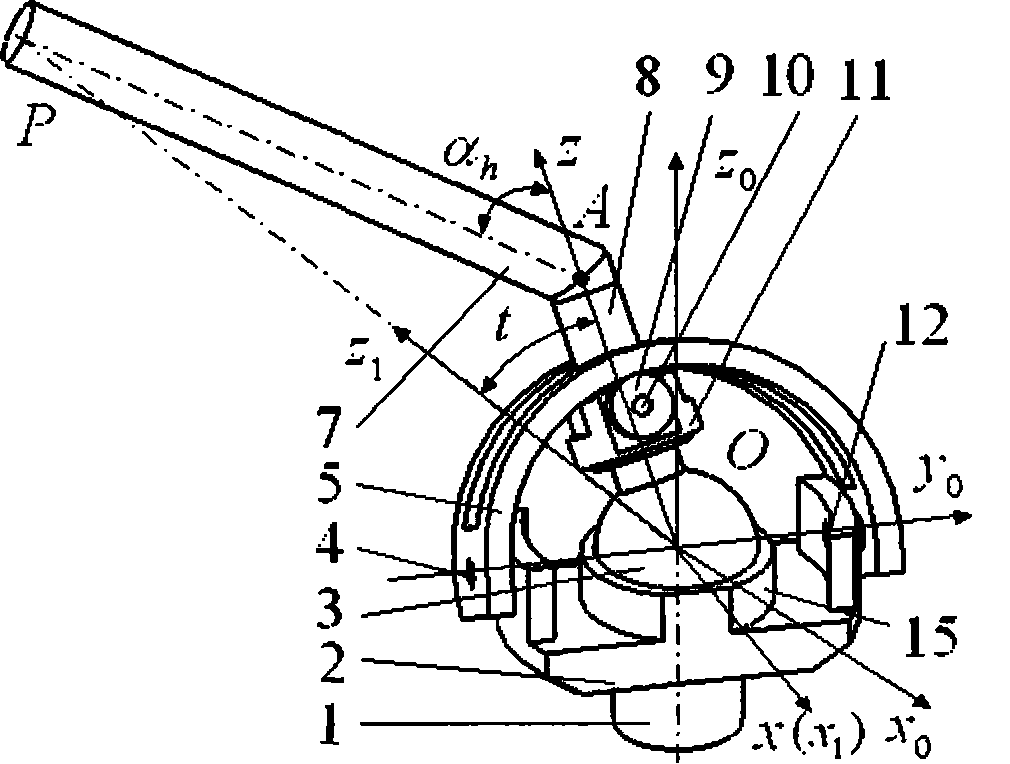

[0049] image 3 The second disclosed embodiment of the present invention consists of a spherical hinge with a large working space and an offset output unit. The bias output unit includes a bias output rod 7 and a straight output rod 8; the spherical hinge with a large working space includes a support unit, an output unit and a spherical sub-unit, and the support unit includes a lower support rod 1, two ears The bracket 2, the U-shaped shift fork 5 and the double-ear bracket 2 constitute pins (4, 12) that are rotationally connected; the output unit includes a straight output rod 8, support rollers (9, 9'), support pins (10, 10') and a rotating bracket 11; Wherein the difference with the first embodiment: the U-shaped shift fork 5 is placed on the outside of the double ear bracket 2; The rod 1 is fixed to the center, and the ball head 3 and the bracket ball socket 15 form a spherical pair.

[0050] The spherical hinge is characterized by: large bearing capacity, slightly smal...

Embodiment 3

[0052] Figure 4 The third embodiment disclosed by the present invention is a spherical hinge with a super large working space based on the bias output of the traditional spherical hinge. It consists of a lower support rod 1, a support ball socket 13, a restraint ball socket 14, a ball head 3, a straight output rod 8 and a bias output rod 7. The upper end of the lower support rod 1 is concentrically fixed with the support ball socket 13, and the axis of the lower support rod 1 coincides with the rotation axis of the support ball socket 13; the lower end of the straight output rod 8 is concentrically fixed with the ball head 3, and the straight output rod 8 takes A certain length OA is greater than the sum of the radius of the restraining ball socket 14 and the radius of the output rod; it is fixedly connected with the offset output rod 7 at the upper end point A to form an output unit, and the axis of the straight output rod 8 and the axis of the offset output rod 7 form an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com