Anchorage cable anchoring construction method

An anchor cable and construction method technology, applied in the field of anchor cable anchoring construction method, can solve the problems of reduced safety, inconvenient installation, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

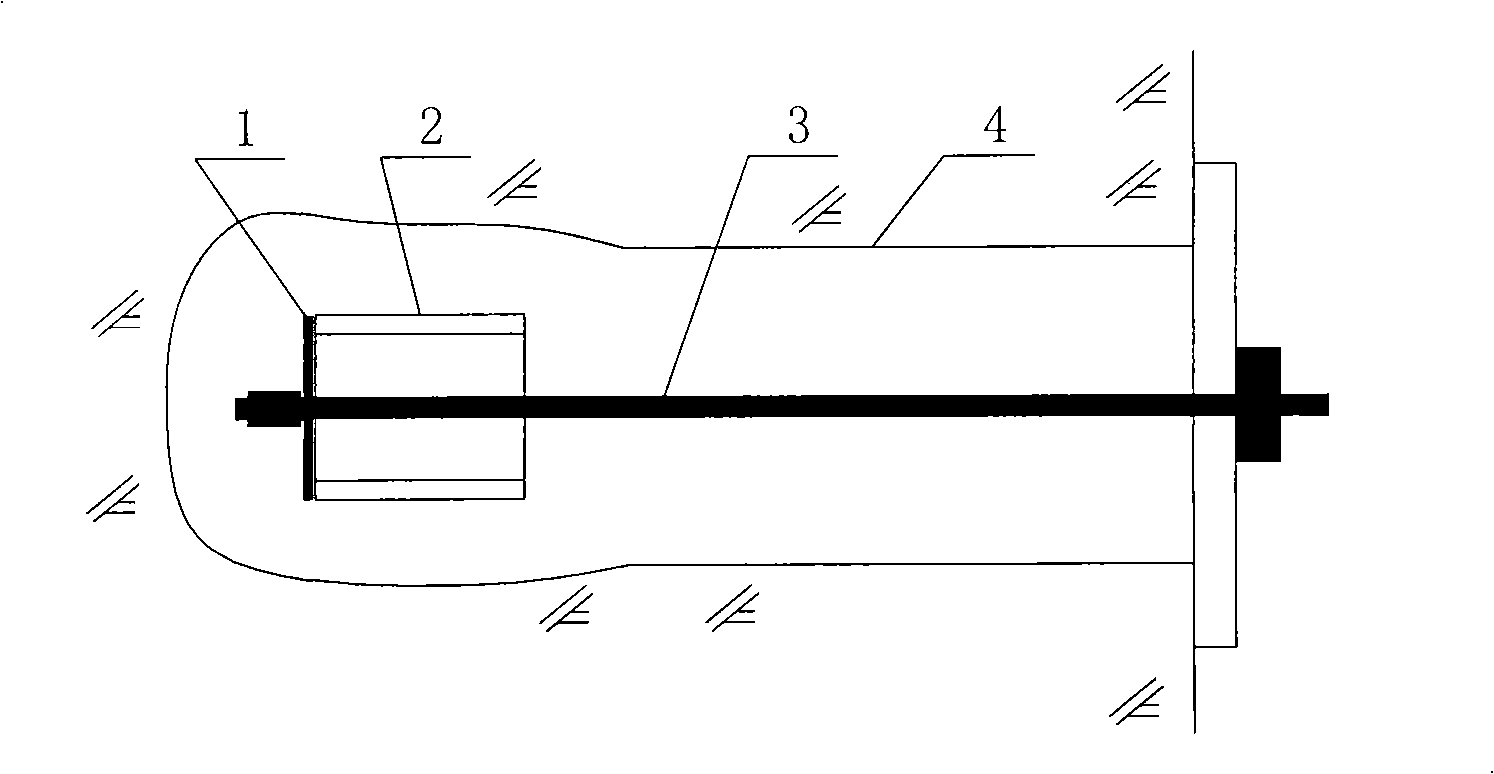

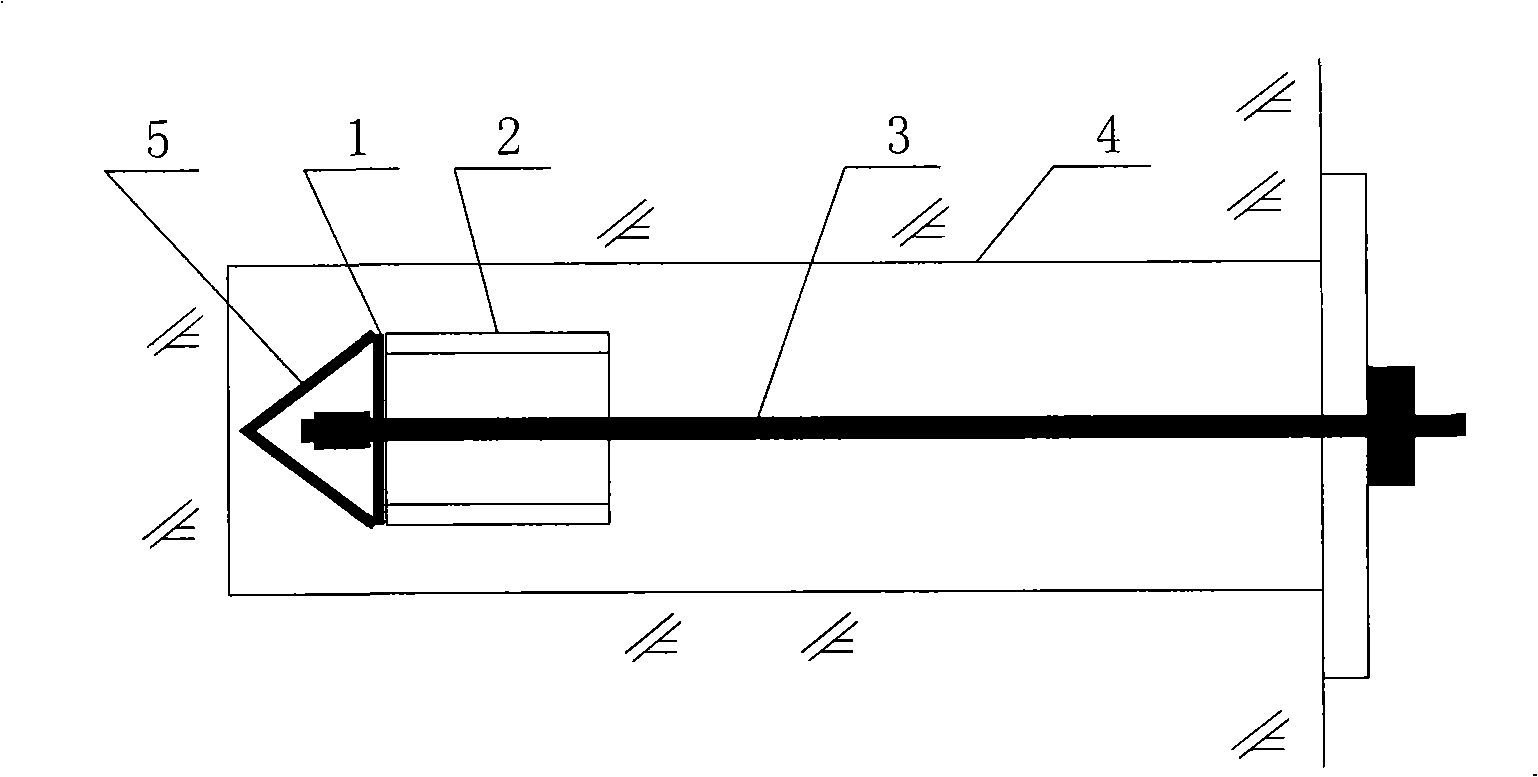

[0015] The bottom end of the unbonded steel strand 3 is equipped with a shear cylinder 2 made of steel, and the front end of the shear cylinder 2 is equipped with a bearing plate 1; when the anchor cable is drilled, the anchor cable structure is used in hard rock. Cylindrical drilling is used, bottom enlarged head drilling is used when used in soft rock or soil, and self-drilling drill bit and pressure shear barrel are combined when used in the stratum that is easy to collapse.

[0016] Figure 1: Before the construction of the anchor cable, drill 4 first, install a steel shearing cylinder 2 at the bottom end of the unbonded steel strand 3, and then install the bearing plate 1 at the front end of the steel shearing cylinder 2 to complete the installation The anchor cable of the shear cylinder is placed in the bore 4.

[0017] Figure 2: Before the construction of the anchor cable, drill 4 first. After drilling 4 is completed, the bottom of the hole is reamed to form an enlarged head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com