Dust-removing blowing device

A blowing device, a new type of technology, is applied in the direction of physical therapy of artificial filaments, complete sets of equipment for the production of artificial threads, and the use of liquid separation agents, etc. It can solve problems such as dust, product defects, and influence on fiber drafting performance, so as to prevent clogging , avoid parallel wires, and improve the uniformity of air outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

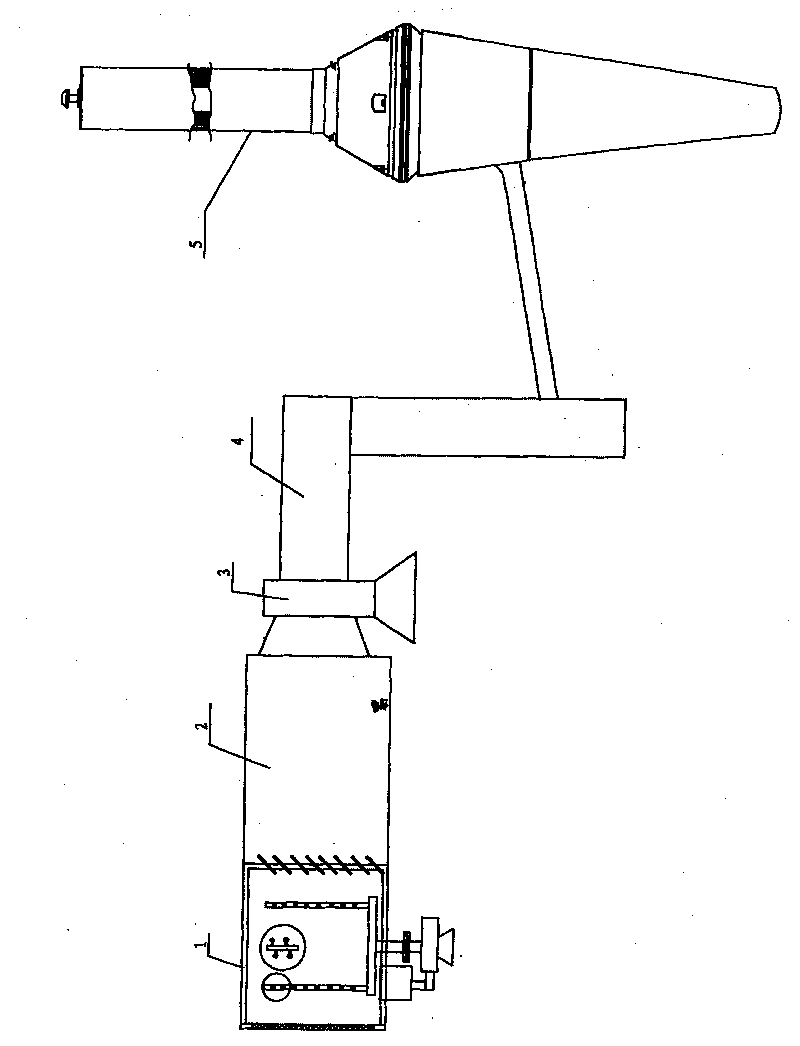

[0014] see figure 1 , The novel dedusting blowing device that the present invention relates to is mainly made up of micro-mist water film dedusting device 1, temperature and humidity air conditioning device 2, blower 3, air supply pipe 4 and three-stage rectification blowing device 5. The air outlet of the micro-mist water film dust removal device 1 is connected to the air inlet of the temperature and humidity air conditioning device 2, the air outlet of the temperature and humidity air conditioning device 2 is connected to the air inlet of the blower 3, and the air outlet of the blower 3 is connected to the three-stage rectification through the air supply pipe 4 Blowing device 5 air inlets are connected.

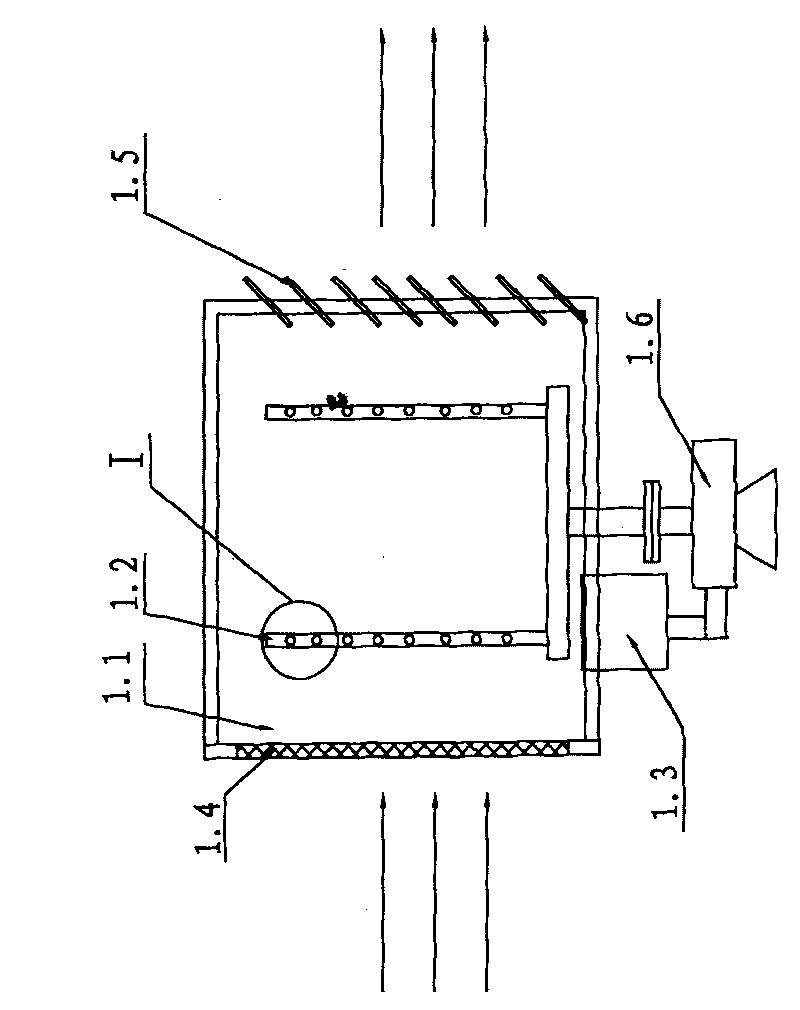

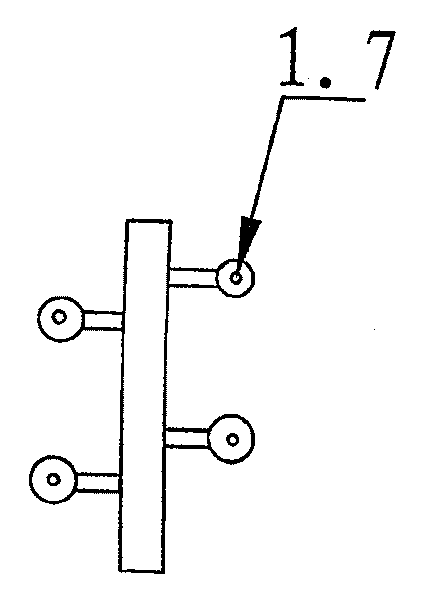

[0015] see figure 2 , the micro-mist water film dust removal device 1 comprises a dust removal chamber 1.1, a spray atomization device 1.2 and a water supply tank 1.3, the air inlet of the dust removal chamber 1.1 is equipped with an air filter 1.4, and the air outlet is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com