Connection hardware for wooden building

一种金属件、建筑用的技术,应用在木构造建筑用连结金属件领域,能够解决施工完成交工期延迟、积载量变少、成本增加等问题,达到耐火性及热桥飞跃性提高、减少积载空间、施工效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

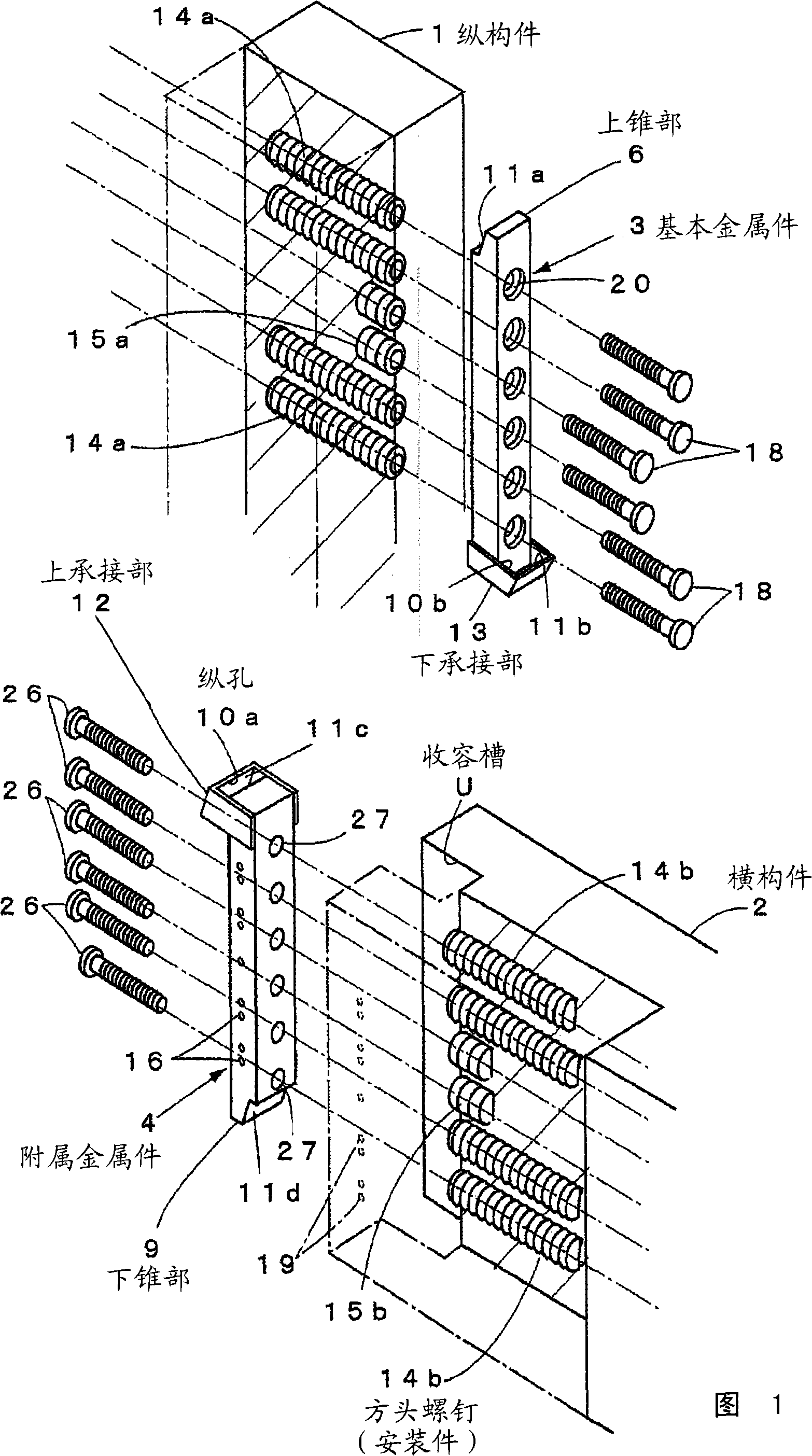

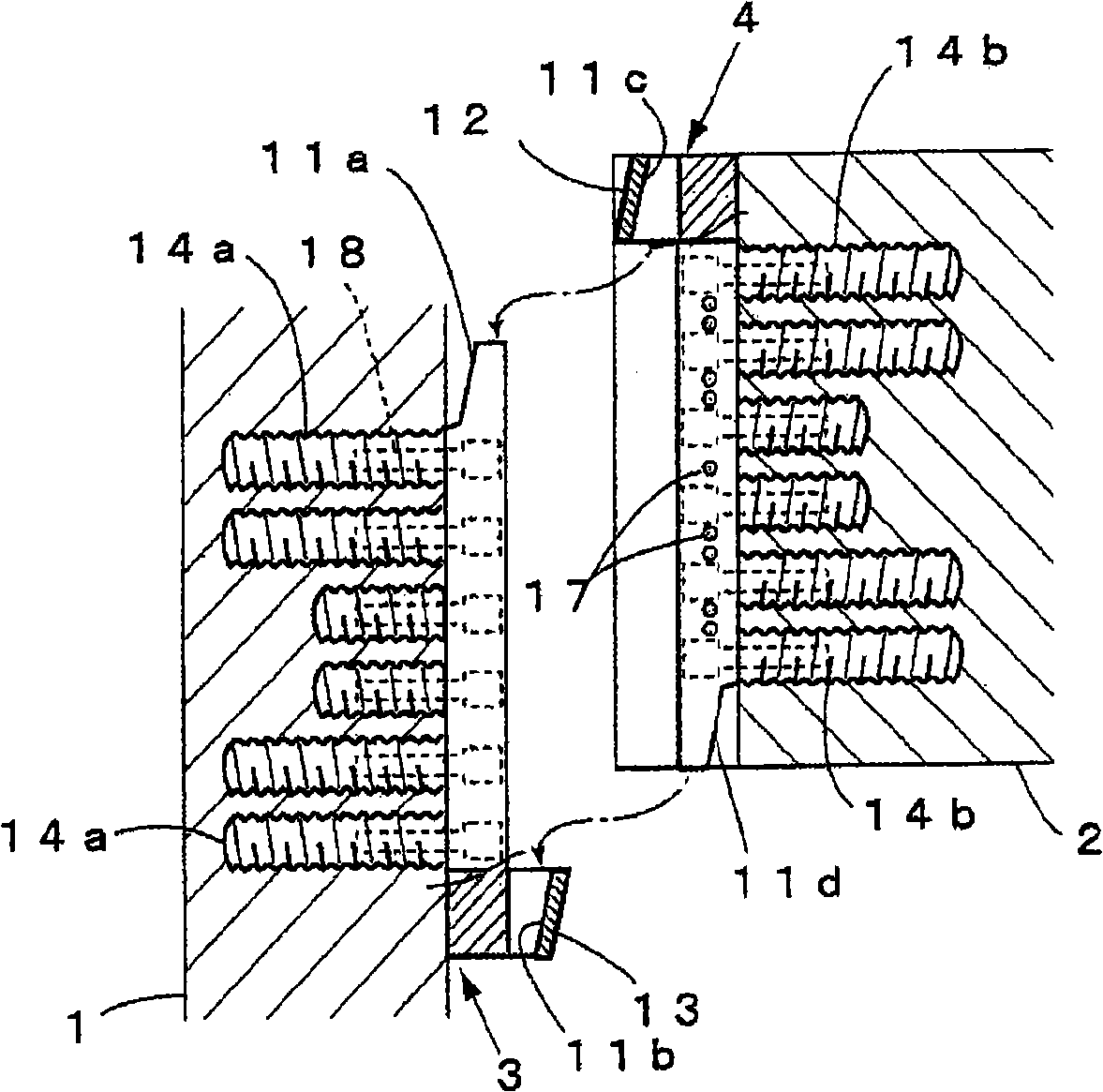

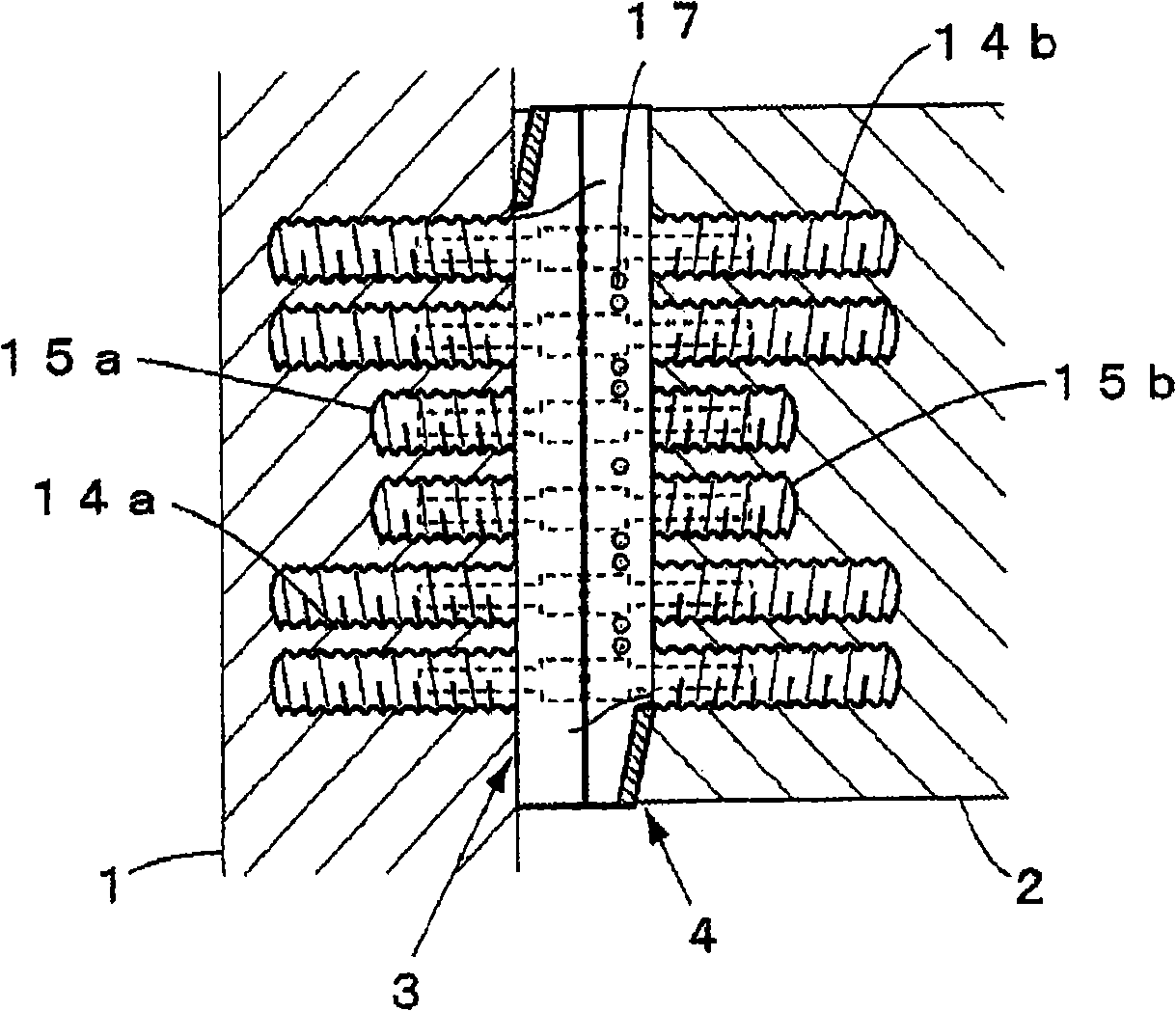

[0025] As shown in Figure 1, the first embodiment of the connecting metal fittings for wooden structures of the present invention consists of basic metal fittings 3 fixed on the side surfaces of vertical members 1 and accessory metal fittings 4 housed in the end faces of cross members 2. constitute.

[0026] Lag screws 14a, 15a are pre-screwed into the vertical member 1 on which the basic metal parts 3 are installed, and the attachment of the lag screws 14a, 15a to the vertical member 1 is via the central part in the lateral direction of the side surface of the vertical member 1. It is carried out by using a buried hole created by a drilling tool or the like.

[0027] In addition, since lag screws of reference numeral 15a and reference numeral 15b described later are reinforcing members, they may not necessarily be attached.

[0028] basic metal piece 3 as shown in Figure 1 and Figure 2A , Figure 2B As shown, it is in the shape of a longitudinally long block threaded on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com