Diving crusher

A crusher and crusher technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, grease/oily substance/floating matter removal device, etc., can solve the problem of affecting the service life of the crusher, poor heat dissipation of the motor, Dirt is easy to get stuck on the drum, etc., to achieve the effect of small and compact structure, easy to replace, and reduce thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] figure 1 A submersible crusher shown in , the reduction box 2 and the motor 3 are installed at the bottom of the casing 1 of the crusher, and the motor is installed on the front or rear box of the reduction box perpendicular to the axis of the cutter head. In water, it solves the problems of motor overheating and large equipment installation space.

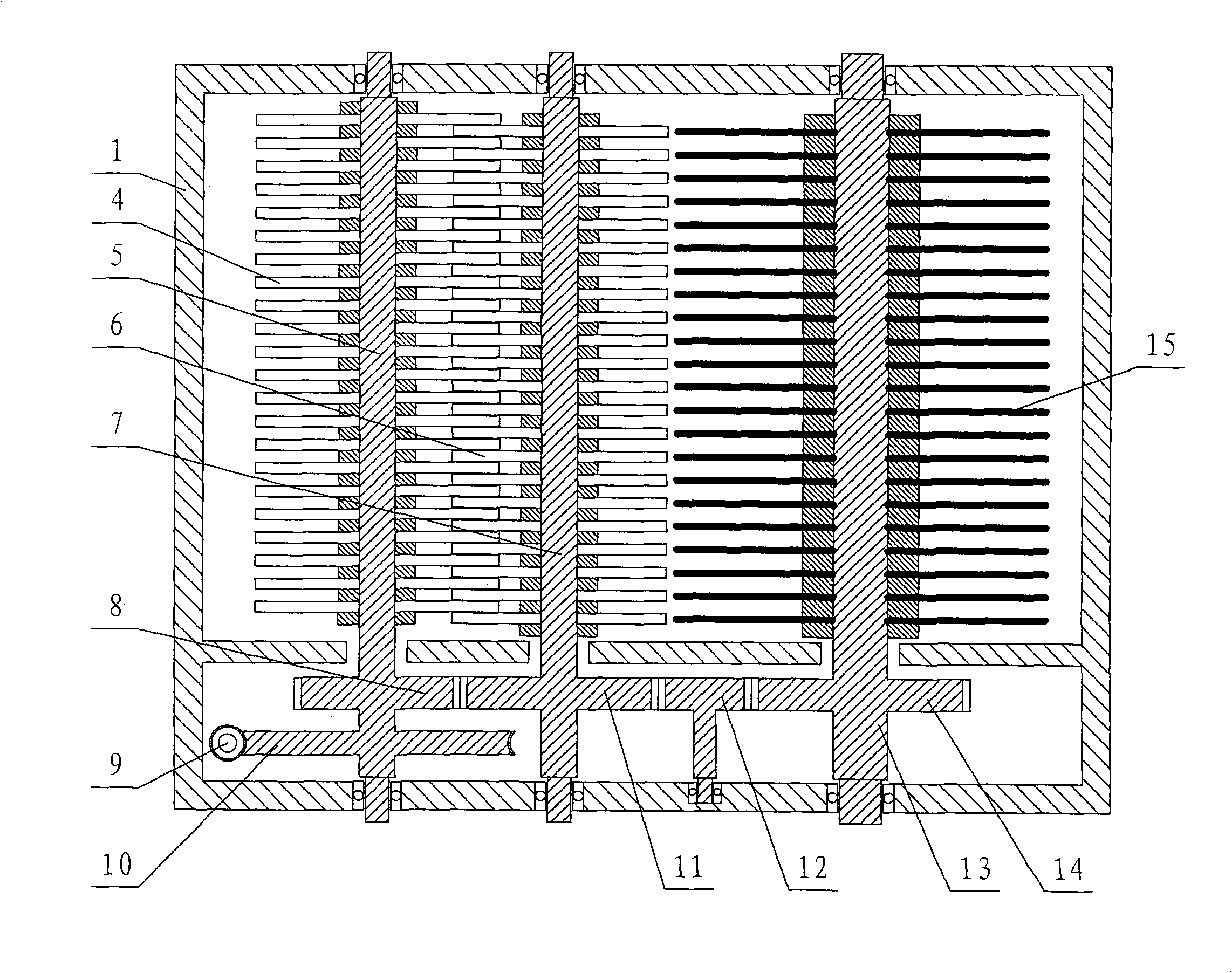

[0018] figure 2 Among them, the crusher is equipped with a double-shaft crusher and a drum. The double-shaft crusher includes two cutterhead shafts 5, 7 and cutterhead groups 4, 6 installed on the two cutterhead shafts, and installed on two cutterhead shafts. The driving gear 8 and the driven gear 11 on the cutter head shaft, wherein a worm gear 10 meshed with the reduction box worm 9 is installed on one of the cutter wheel shafts. The motor works, so that the reducer worm meshes with the worm gear to drive a cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com