Prestress concrete box girder hydraulic internal mold vehicle as well as hydraulic internal mold system

A prestressed, box girder technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty in demoulding, and achieve the effects of convenient demoulding, small design load, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

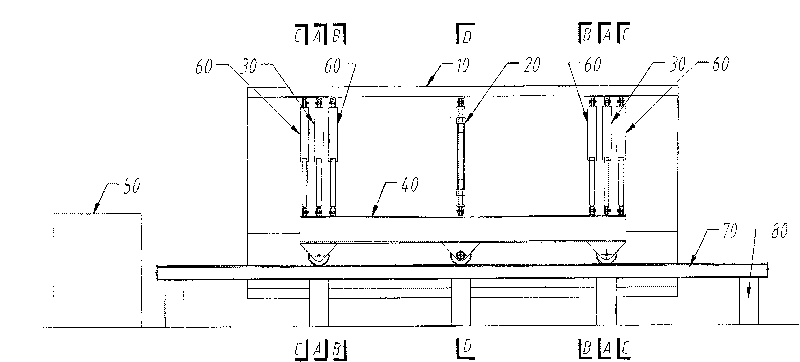

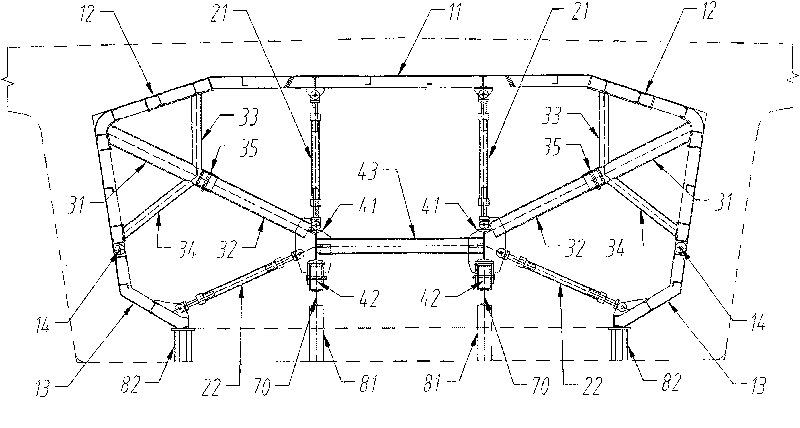

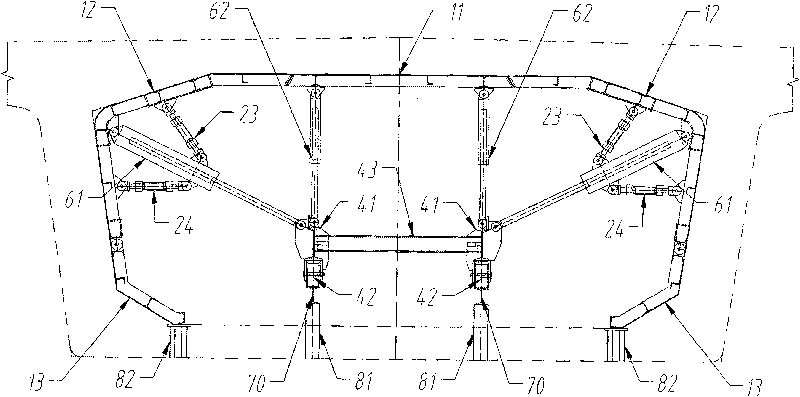

[0032] Figure 1 to Figure 5 It is the state when the template in the combination of the present invention is supported.

[0033] Such as figure 1 As shown, the present invention is mainly composed of combined inner formwork 10, several groups of adjustable struts 20, several groups of sleeve struts 30, longitudinal moving trolley 40 and several groups of hydraulic cylinder groups 60. The combined inner template 10 is fixed on the longitudinal moving trolley 40 through the adjustable strut 20, the sleeve strut 30, and the hydraulic cylinder group 60; the hydraulic cylinder set 60, the adjustable strut 20, the sleeve strut 30 of the present invention They are respectively located in different sections along the longitudinal direction of the hydraulic inner mold car.

[0034] figure 2 for figure 1 The A-A cross-sectional schematic diagram, the A-A cross-section i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com