Compact spinning air-suction duct having branch wind pipe

A suction pipe and compact spinning technology, which is applied in the field of improvement of the concentrated suction device of the compact spinning ring spinning frame, which can solve the problems of unbalanced negative pressure, great difference, and inability to ensure the stability and consistency of the negative pressure value of the concentrated airflow at the suction port, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

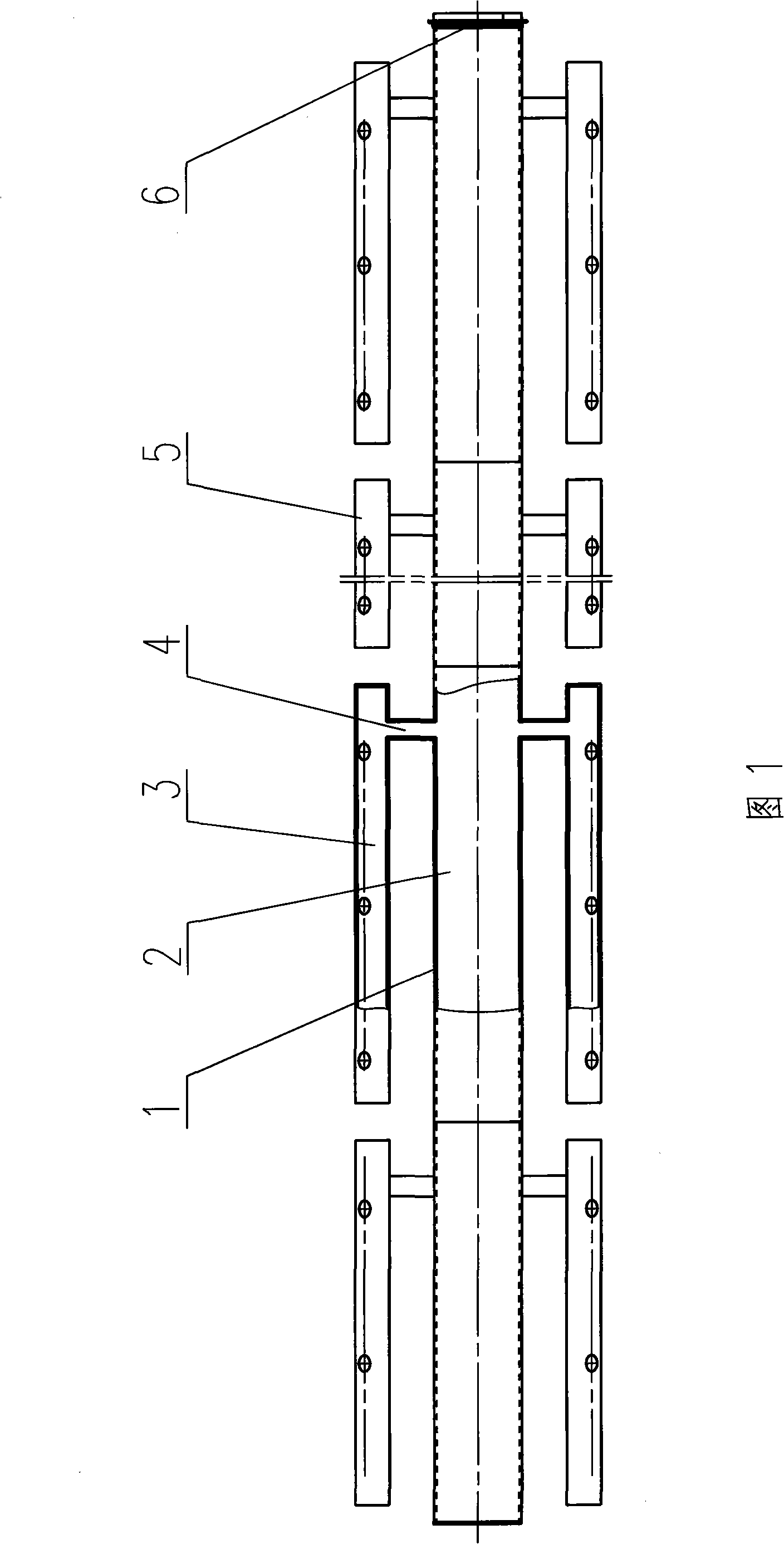

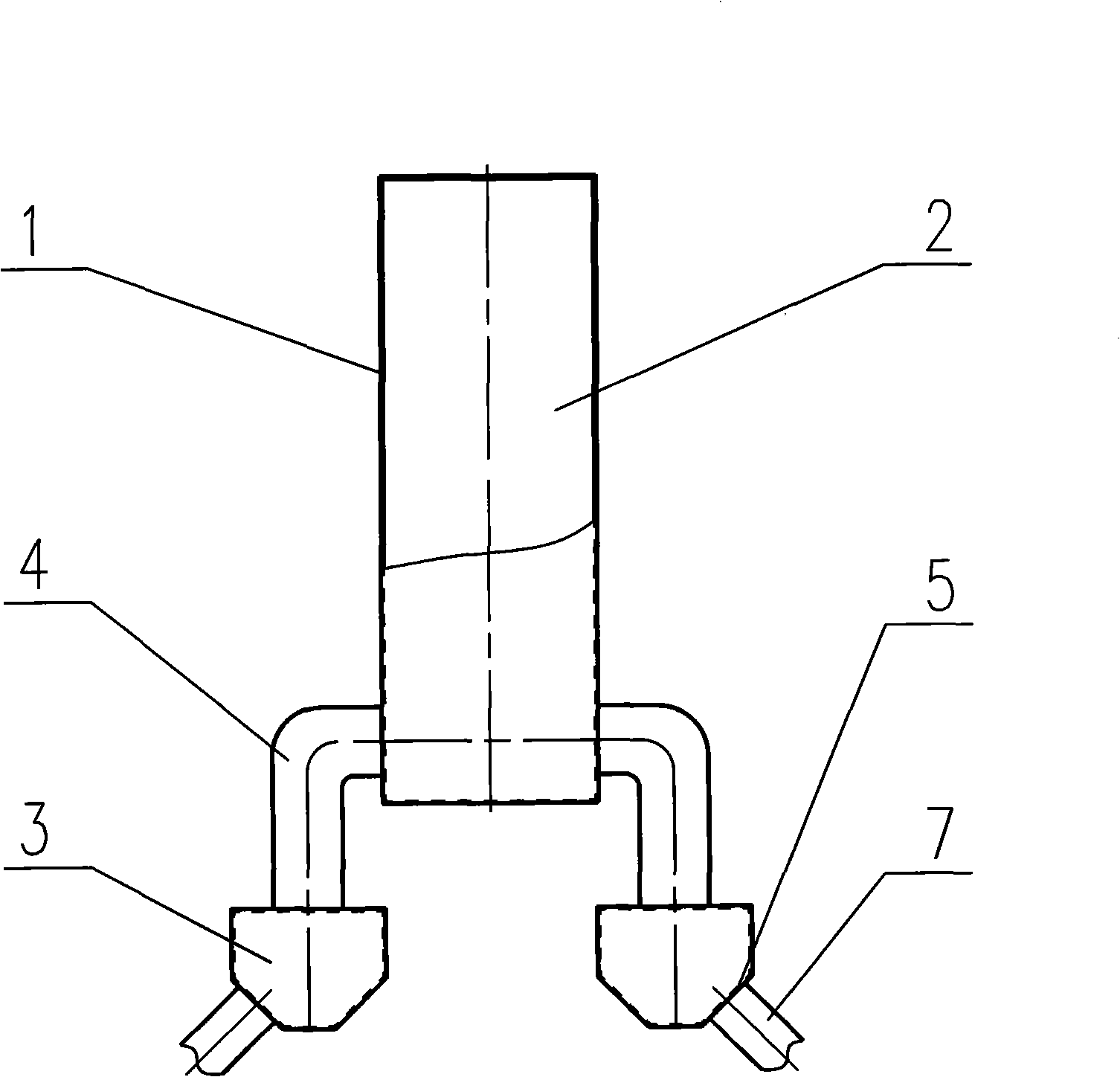

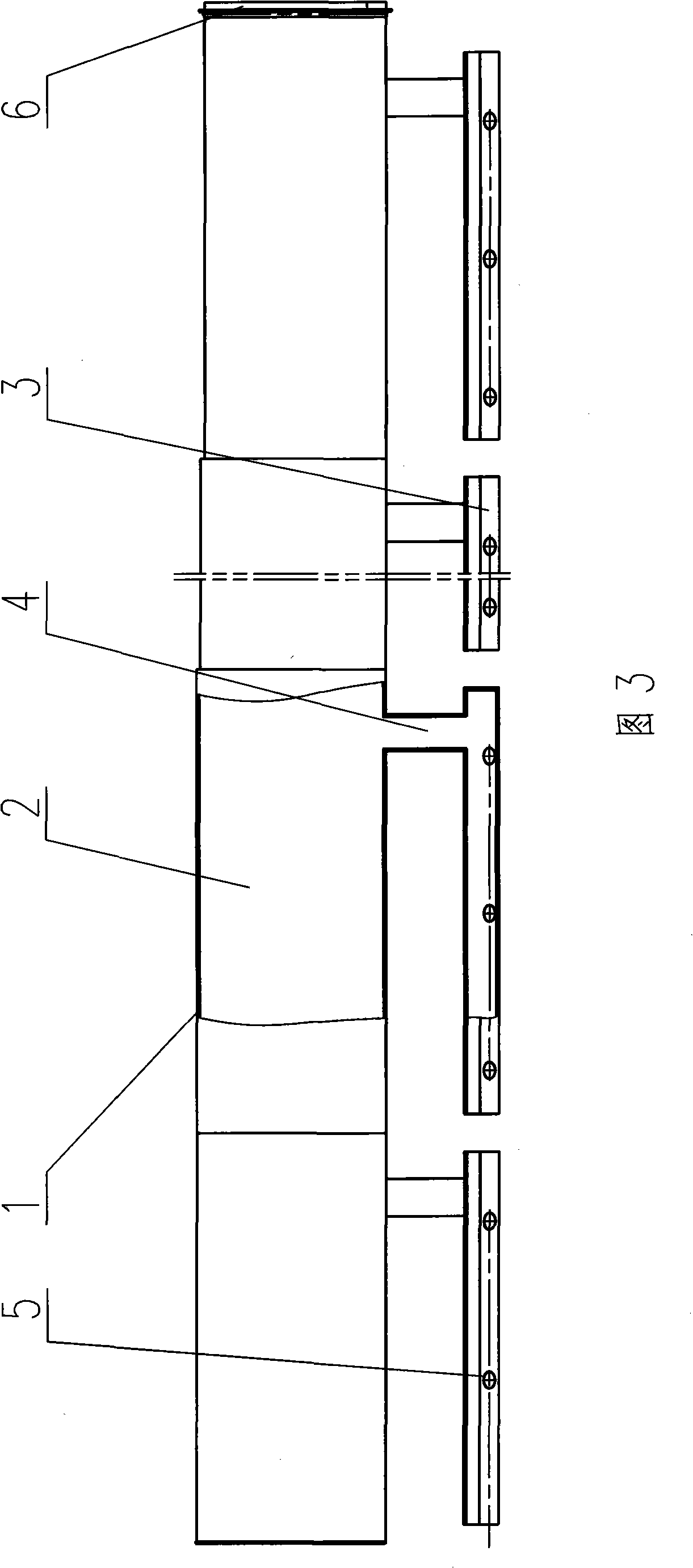

[0023] In Figure 1, figure 2 In the shown compact spinning suction duct with branch air ducts, the main suction duct 1 is a long duct with a rectangular section with a suction lumen 2, one end (tail end) of the long duct is closed, and the other end is the main air duct. A channel fan interface 6, the main air channel fan interface 6 is in sealing connection with the fan suction port. The main suction pipe 1 extends from the rear of the spinning frame to the head of the spinning frame, and its length is roughly equal to the length of the spinning frame. The main suction pipe 1 is formed by splicing several suction pipe sections in a sealed manner. The length of the main suction pipe 1 and the number of spliced sections are determined according to the actual working length of the spinning frame. The cross-sectional sections of the main suction pipe 1 are equal. Thus having the same ventilation flow. Several suction branch pipes 3 are arranged symmetrically on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com