Groove processing method and forming rotary cutting tool

A technology of cutting tools and processing methods, applied in the field of groove processing methods and forming rotary cutting tools, can solve problems such as difficult cutting speed groove processing, and achieve the effects of efficient groove processing, increasing cutting speed and feed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0052]

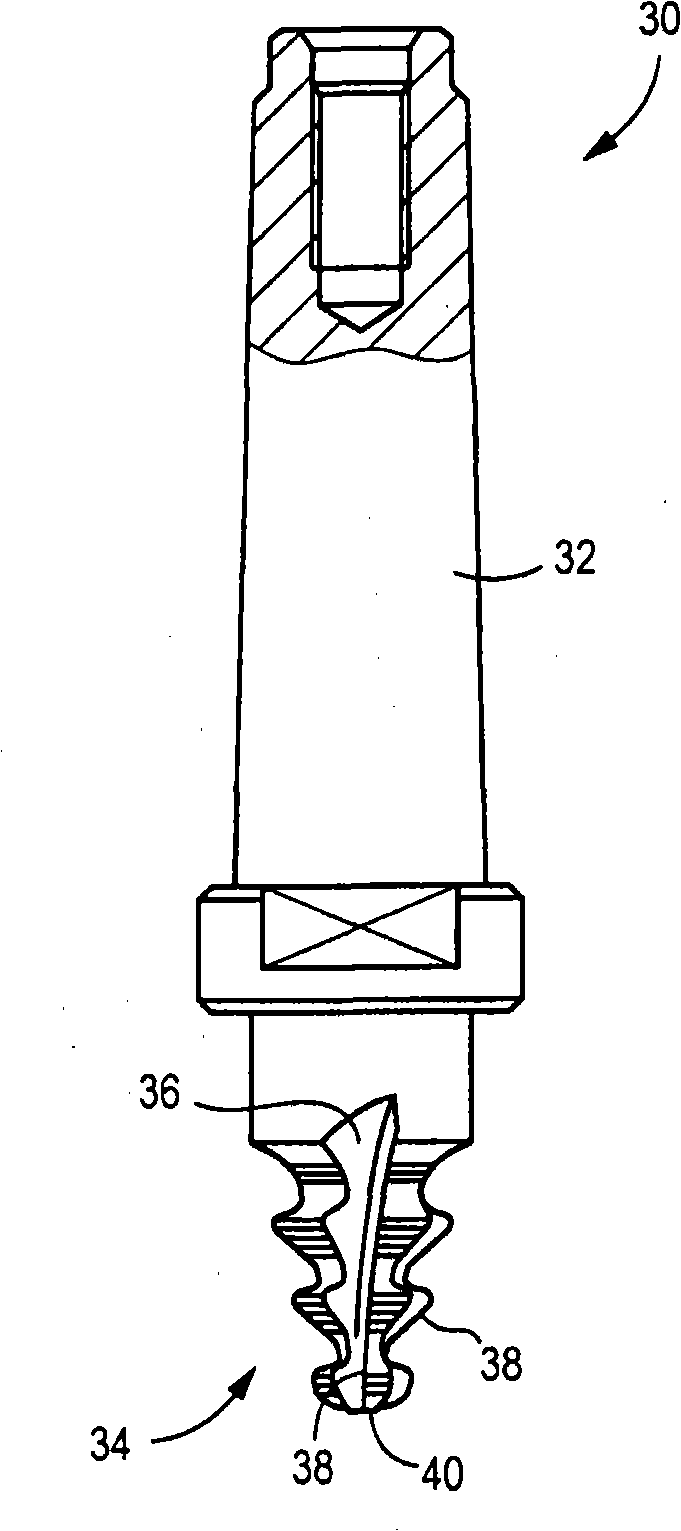

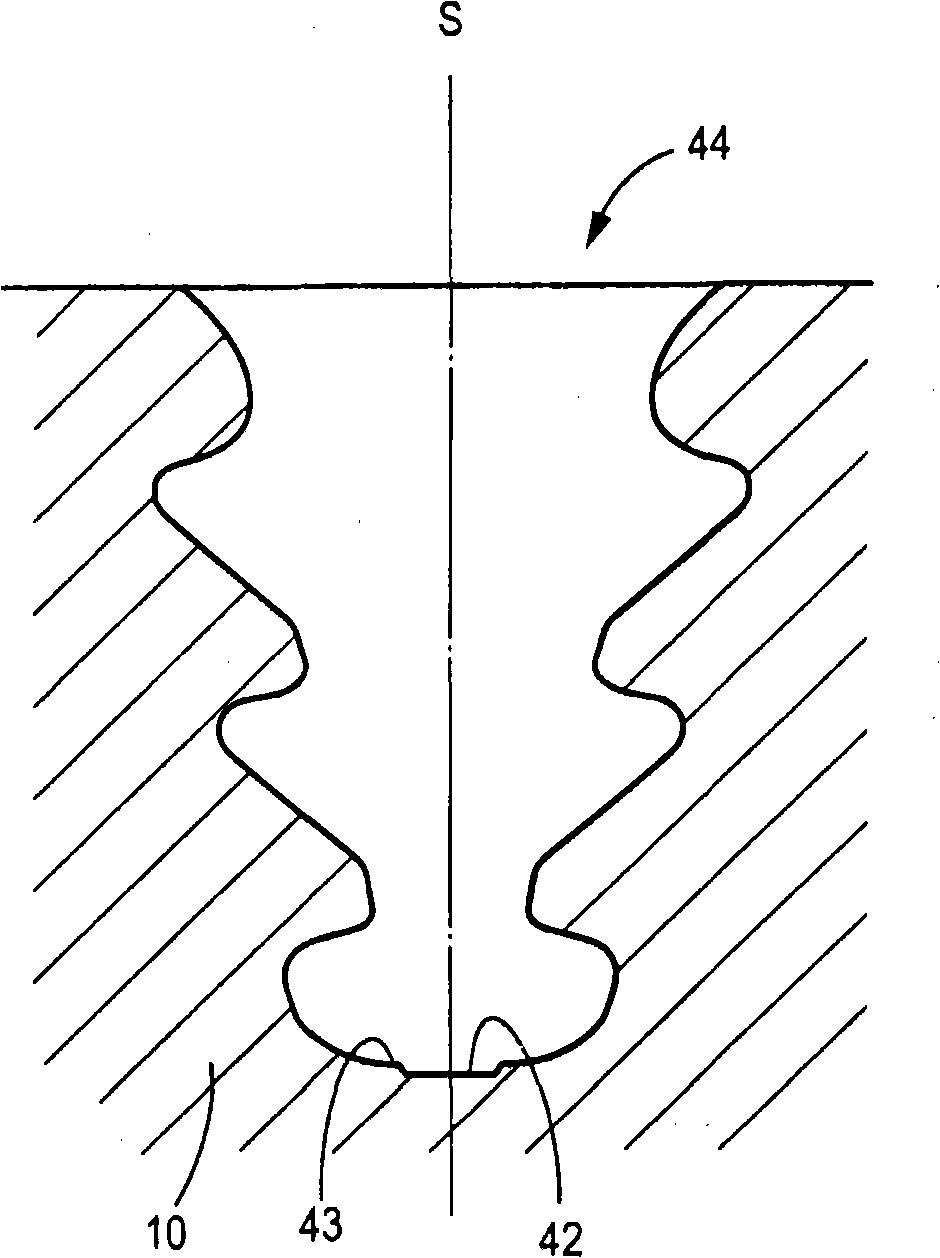

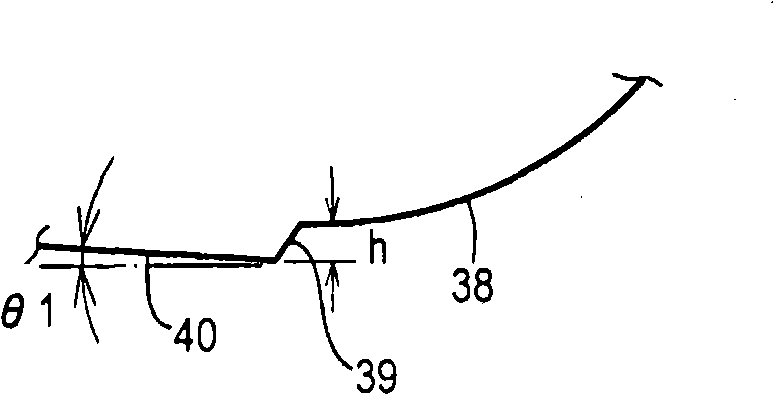

[0053] Figure 1 shows a Christmas tree cutter 30 for roughing and Figure 2 shows a Christmas tree cutter 50 for finishing, both of the milling cutter type. Both cutters 30 and 50 are used for cutting Figure 8 The above-mentioned tree-shaped grooves 12 are all of the rotary tool type, that is, in the case of rotating around their axis, they move in a direction perpendicular to their axis with respect to the workpiece (rotation axis 10). The Christmas tree cutter 30 for roughing, sometimes referred to as a "roughing cutter", corresponds to the claimed roughing forming rotary cutting tool for forming the roughing groove 22 .

[0054] In this embodiment, the roughing tool 30 is used to form a roughing groove 44 provided with a groove 42 on its bottom surface 43 . The roughing tool 30 cuts the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com