Composite DDR type zeolite film, and method for preparation thereof

一种制造方法、复合物的技术,应用在气体分离装置,DDR型沸石膜复合物及其制造,DDR型沸石膜的制造领域,能够解决不能确保气体透过量、压力损失变大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

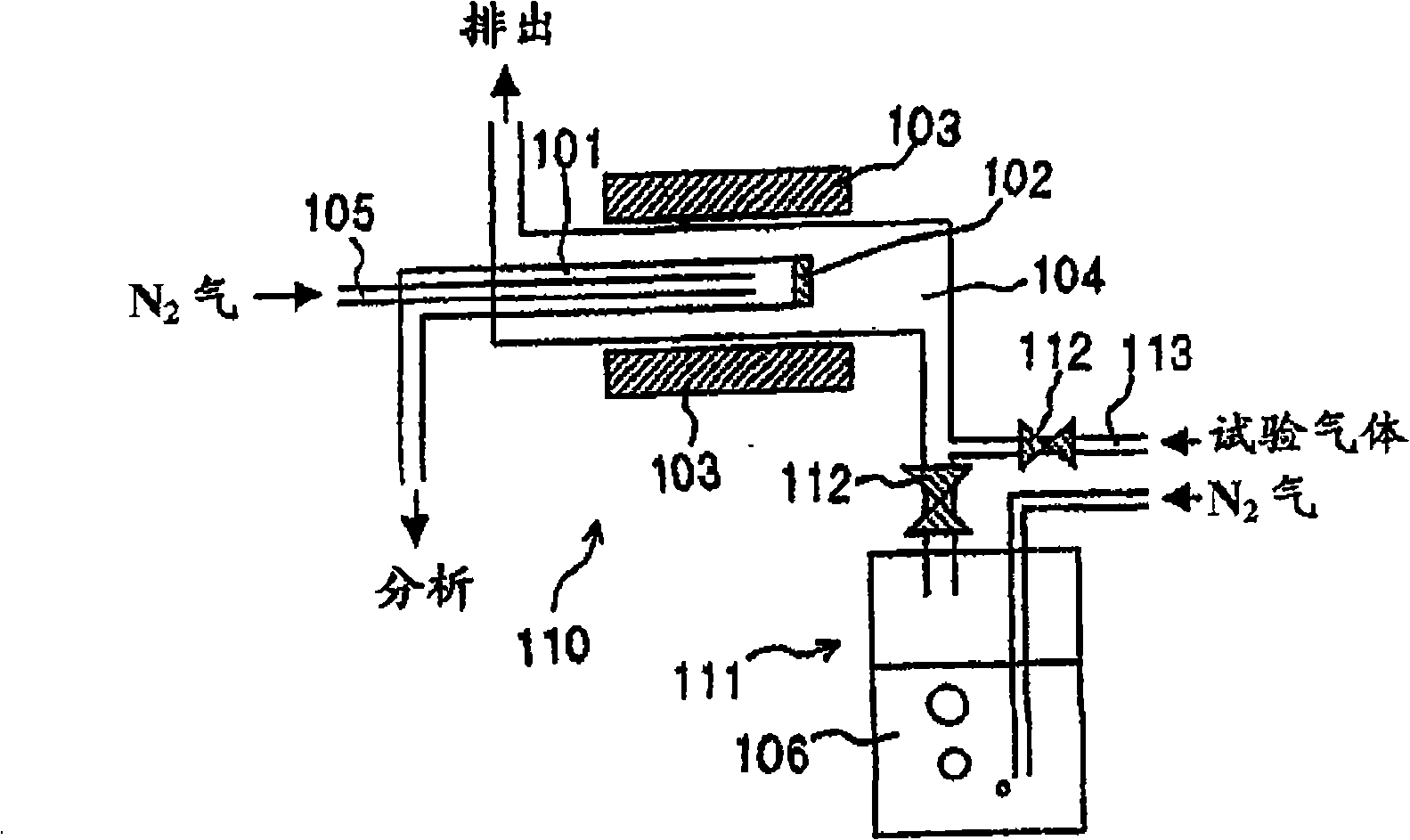

[0150] 1.80 g of ethylenediamine (Wako Pure Chemical Industries Co., Ltd.) was put into a 100 ml jar made of fluororesin, and then 0.57 g of 1-adamantanamine (Katayama Chemical Industry Co., Ltd.) was added and dissolved until no 1 - Precipitated residue of amantadine. Add 73.45 g of water to another beaker, add 3.0 g of 30% by mass silica sol (Snowtex S, Nissan Chemical Co., Ltd.), stir gently, and then add it to a wide-mouthed mixture of ethylenediamine and 1-adamantanamine bottle and shake vigorously to make stock solution. At this time, 1-adamantanamine / SiO 2 The ratio of water / SiO is 0.25 2 The ratio of 280, ethylenediamine / 1-amantadine ratio of 8.

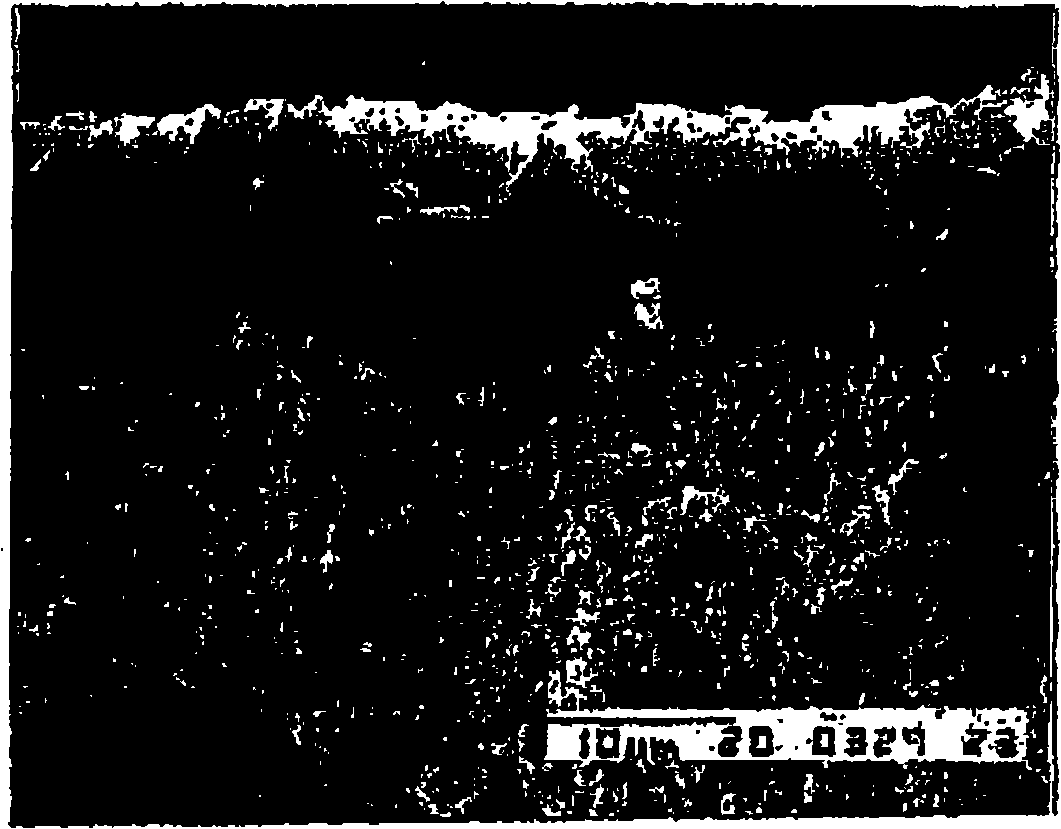

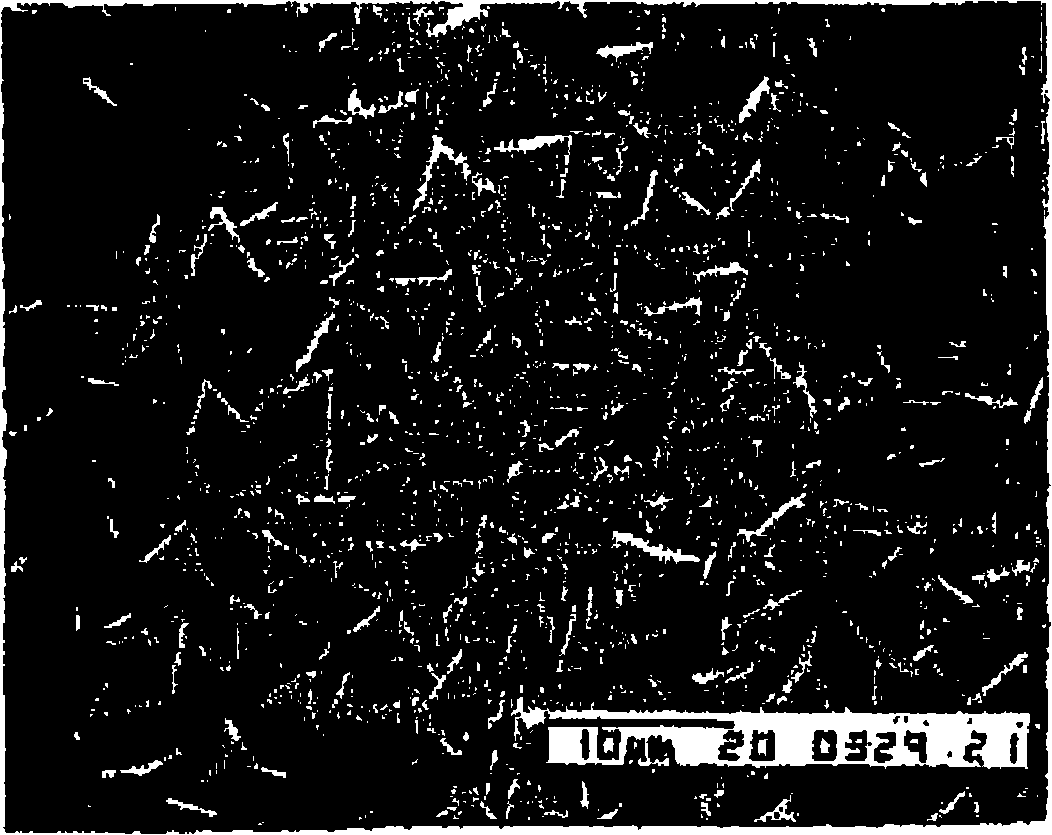

[0151] The jar filled with the raw material solution was placed on a shaker, and shaken and mixed at 500 rpm for another 1 hour. Then, 0.1 mg of the DDR-type zeolite powder obtained by the above-mentioned method for producing DDR-type zeolite powder was added as a seed crystal, and the mixture was kept at 65° C. and ult...

Embodiment 2-12、 comparative example 1-3

[0155] Except for changing the composition ratio of the raw material solution and the heat treatment conditions, the same operation as in Example 1 was carried out, and an attempt was made to form a DDR type zeolite membrane. In the same manner as in Example 1, the obtained film was evaluated by X-ray diffraction, and the film thickness was measured by observation with an electron microscope. The composition ratio of the raw material solution (1-adamantanamine / SiO 2 ratio, water / SiO 2 ratio and ethylenediamine / 1-adamantanamine ratio), heat treatment conditions (temperature, time) and the film thickness of the formed DDR zeolite membrane are shown in Table 1.

Embodiment 13

[0160] Except for using 1.50 g of ethylenediamine, 0.47 g of 1-adamantanamine, 2.50 g of 30% by mass silica sol, and 48.70 g of water, the same operation as in Example 1 was carried out to prepare a raw material solution. At this time, 1-adamantanamine / SiO 2 The ratio is 0.25, water / SiO 2 The ratio was 220 and the ethylenediamine / 1-adamantanamine ratio was 8.

[0161] A porous alumina body with an average pore diameter of 0.6 μm (Nippon Yasuko Co., Ltd.) was processed into A disc-shaped porous matrix, as a porous matrix. The DDR-type zeolite powder obtained by the above-mentioned method for producing DDR-type zeolite powder was used as a seed crystal, which was added to water to prepare a dispersion liquid with a concentration of 1 mg / ml, which was applied dropwise on one side of the porous substrate. This porous substrate was vertically placed in a stainless steel pressure vessel having an internal volume of 100 ml of a fluororesin inner cylinder, and immersed in the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com