Laminar article for electrical use and a method and machine for producing said article

A layered product and electrical technology, which is applied in the direction of metal layered products, layered products, inductors/transformers/magnets, etc., can solve the problems of inability to ensure maintenance of helical angle lamination compensation, insufficient effectiveness, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

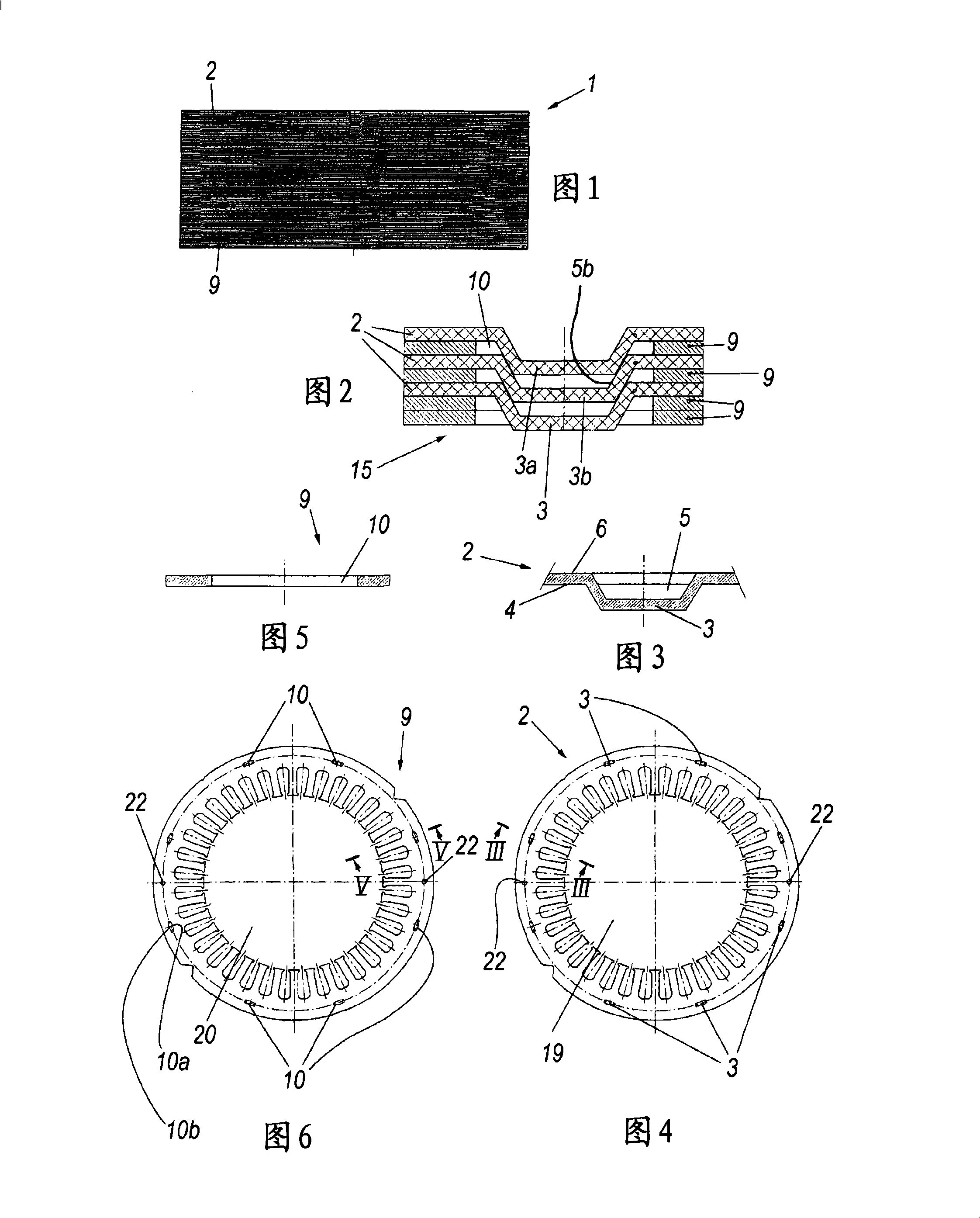

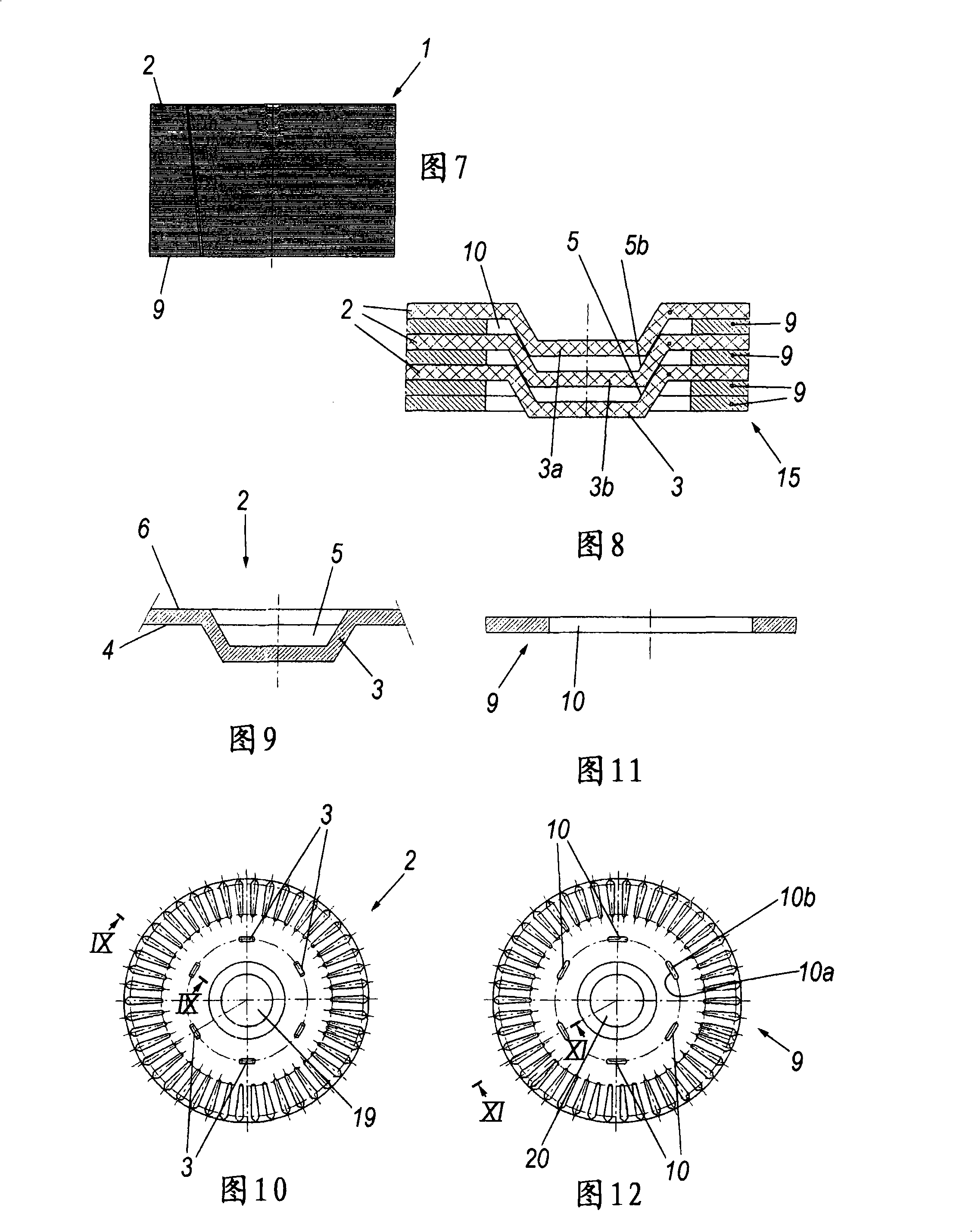

[0051] The rotor described in the first embodiment is, for example, a rotor of an electrical device such as a motor; it is shown in Figs. 7-12.

[0052] It comprises a plurality of first laminations 2 fixedly connected together with second laminations 9 interposed therebetween.

[0053] Each first lamination 2 has six fasteners 3 and the second lamination 2 correspondingly has six holes 10 which are interfered by fasteners 3 on both their inner circumferential side 10 a and outer circumferential side 10 b through.

[0054] A first end 15 has two mutually adjacent second laminations 9 held by fasteners 3 and the opposite end has two first laminations 2 held together directly by fasteners 3 and grooves 5 .

[0055]In this case, the diameter of the holes 19 in the first lamination 2 and the diameter of the holes 20 in the second lamination 9 are equal.

no. 2 example

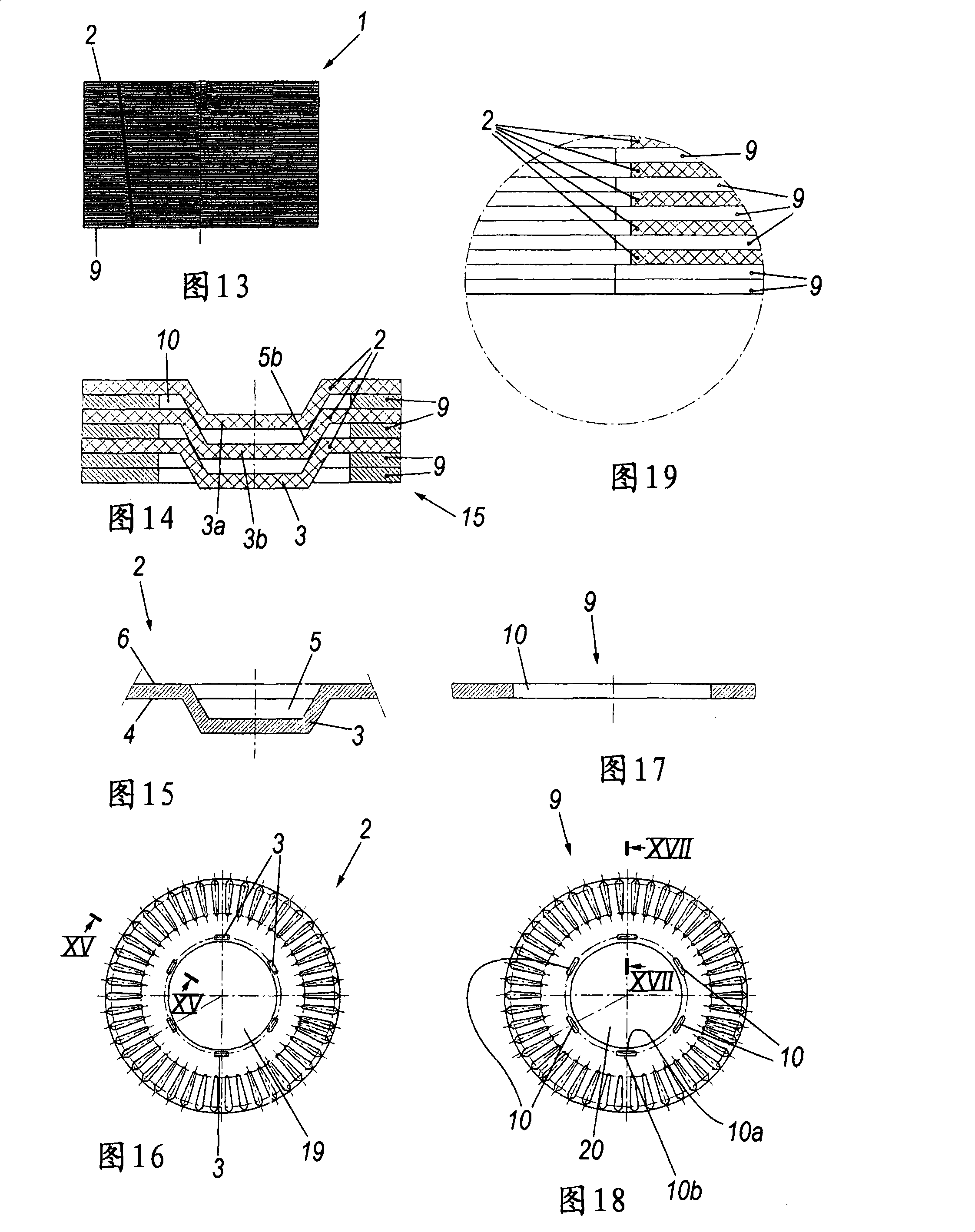

[0057] A rotor according to a second embodiment is shown in Figures 13-18.

[0058] It has a similar structure to the rotor described in the first embodiment.

[0059] In this case, however, the diameter of the hole 19 in the first lamination 2 is greater than the diameter of the hole 20 in the second lamination 9 .

[0060] The invention also relates to a method of manufacturing said layered product for electrical use.

[0061] The method involves die-cutting a plurality of laminations from a sheet metal, rotating and stacking the die-cut laminations, and then securing them together in a predetermined manner.

[0062] The laminations are punched with their reference axes rotated about the reference axis of the sheet metal through a predetermined angle to limit the rotation imparted to the laminations during their mutual fixation.

[0063] The invention also relates to a plant for the manufacture of said layered product for electrical use.

[0064] The apparatus comprises: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com