Emulsifying explosive loading trolley

A technology of emulsion explosives and charge, which is applied in the field of mining machinery and equipment, can solve the problems of natural detonation safety accidents and affect safety production, and achieve the effects of low production cost, practical operation, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

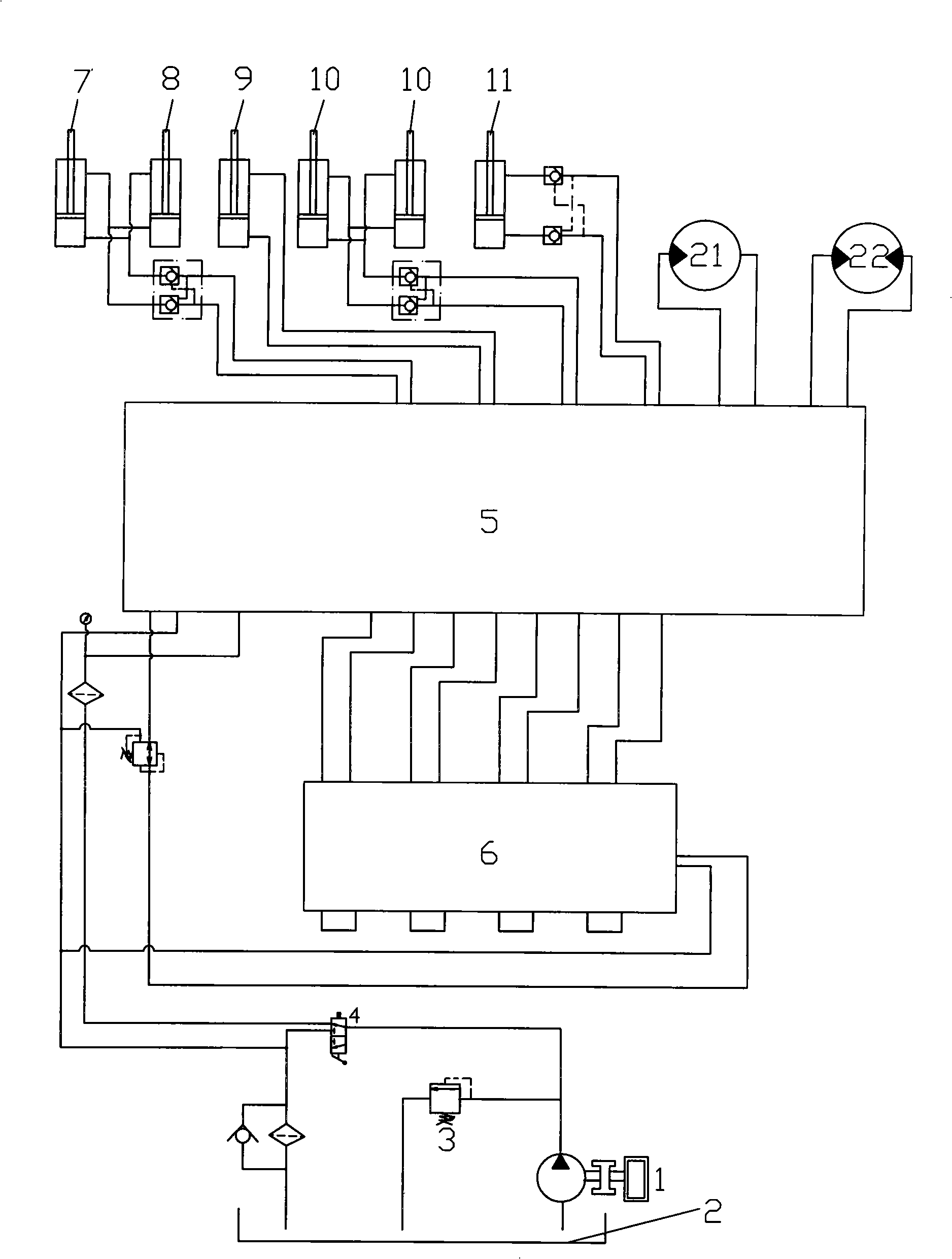

[0016] see figure 1 , Figure 2 and image 3 , an emulsion explosive charging trolley, including the hydraulic control system of the working arm and the emulsion explosive charging system. The pressure of the entire working system can be adjusted through the overflow valve 3, and the proportional valve group is installed on the frame. Its main function is Hydraulic control or manual operation of the working boom and flow distribution and pressure adjustment of the hydraulic oil; the control valve group 6 is installed on the working basket, and its function is mainly to use the pilot oil to control the action of the proportional valve group 5 to achieve the operation of the working boom . Therefore, when the operator needs to perform various actions on the working arm on the ground, the proportional valve group 5 can be manipulated to change the oil cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com