Siphon jet w.c.pan

A siphonic, toilet technology, applied in flushing equipment with water tanks, flushing toilets, urinals, etc., can solve problems such as consumption of flushing water, delay in starting, inability to meet water saving, etc., and achieve high flushing function and saving amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

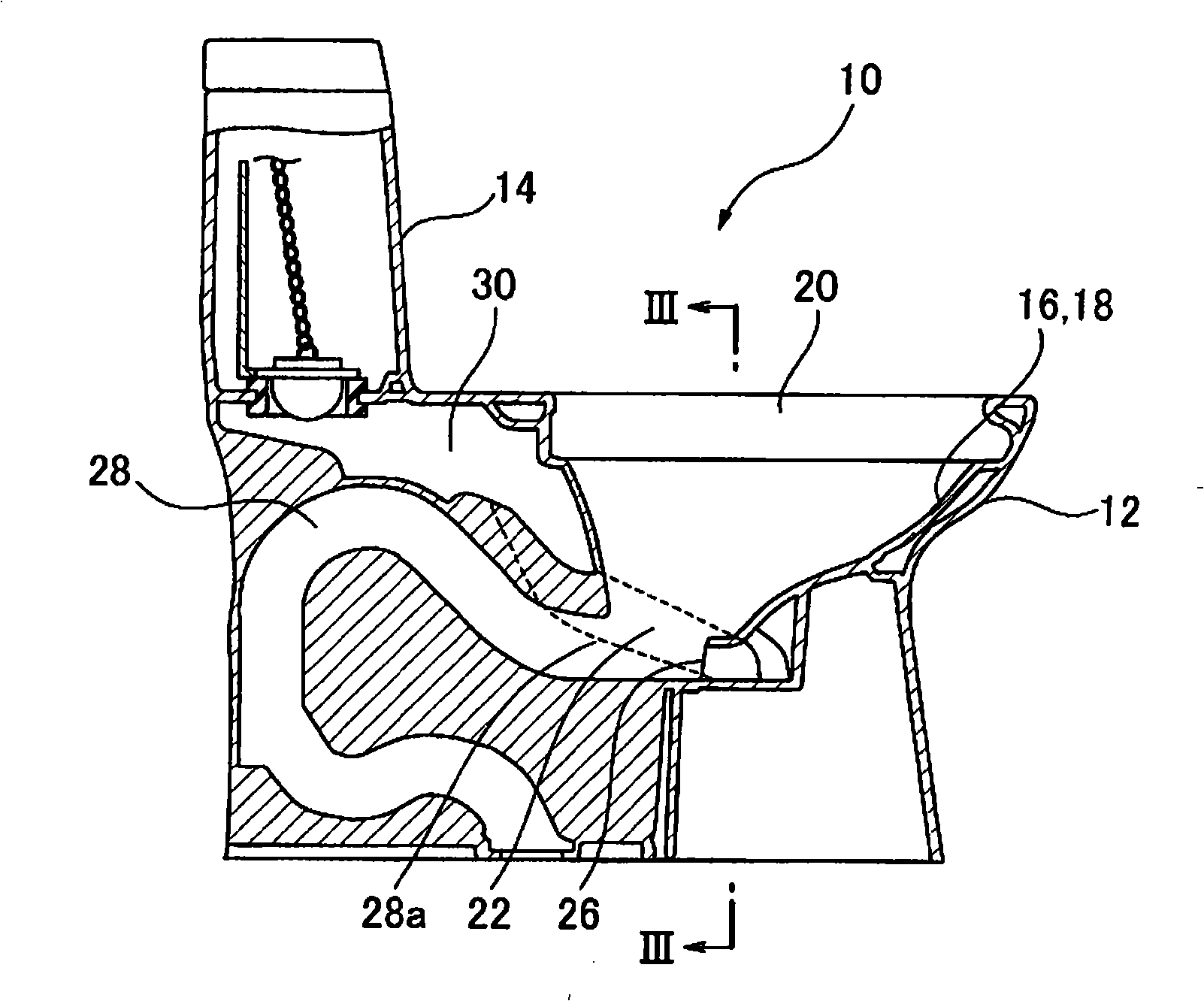

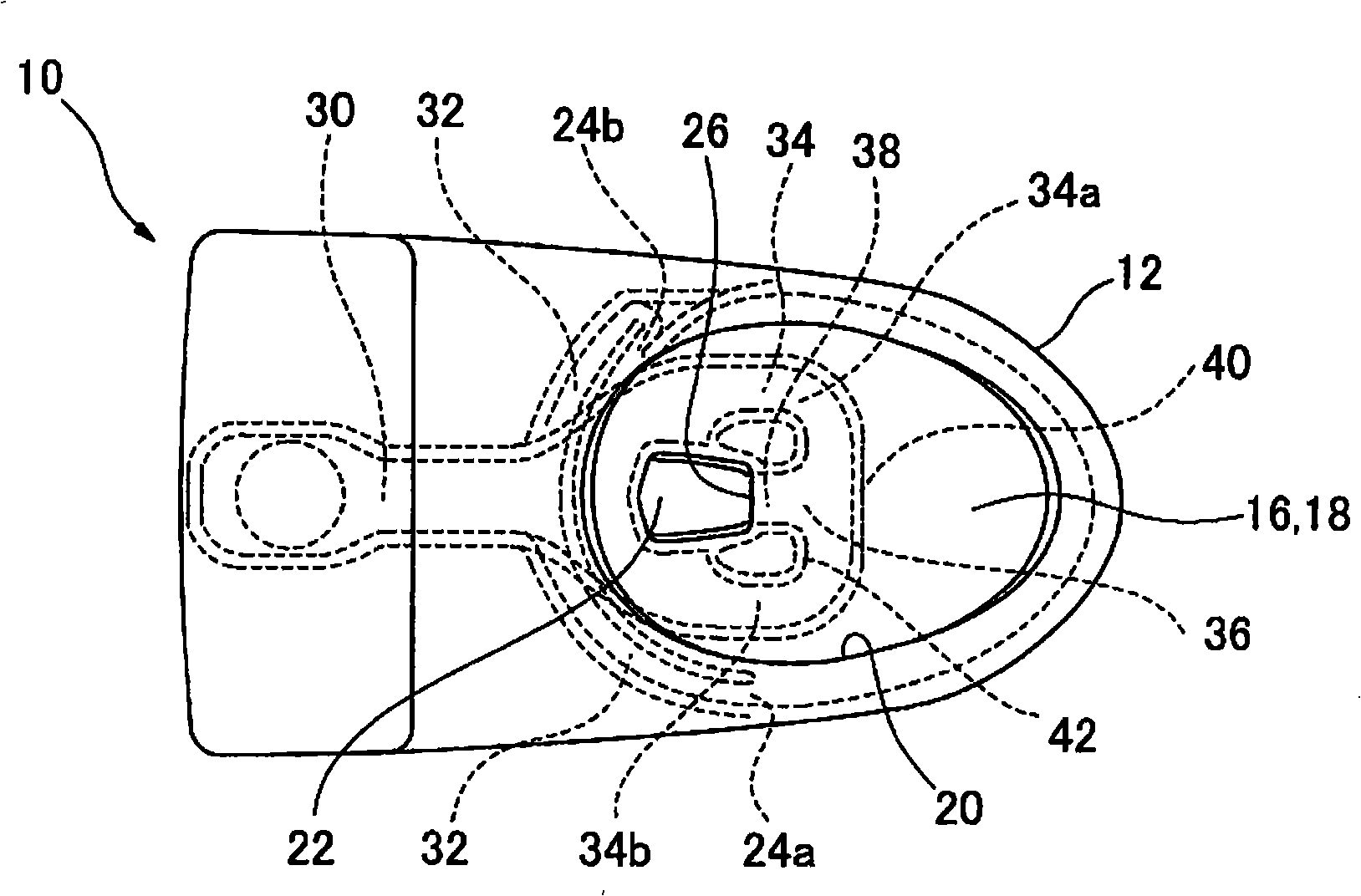

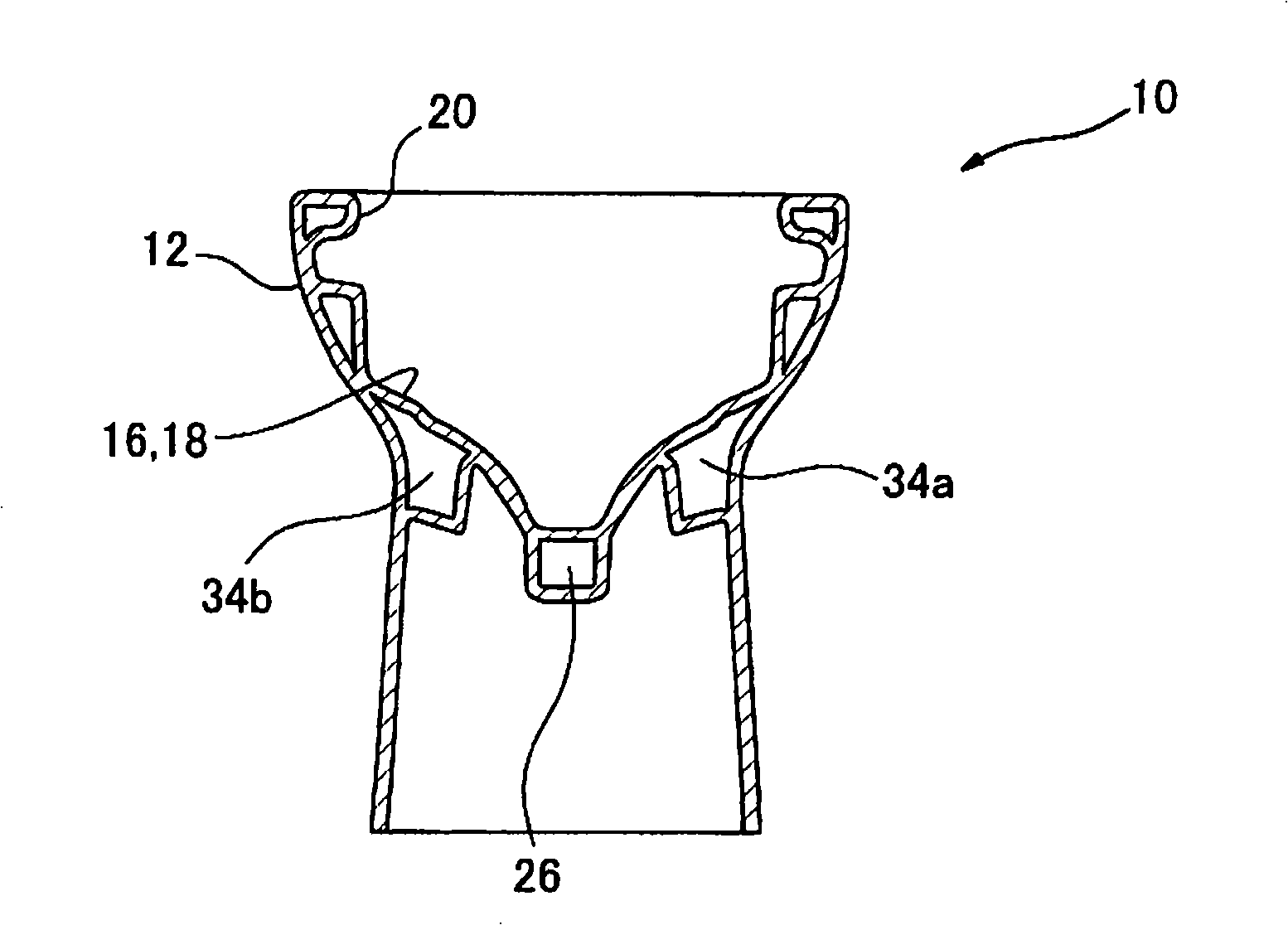

[0058] Next, a jet siphon toilet according to an embodiment of the present invention will be described with reference to the drawings. First, through Figure 1 to Figure 3 The basic structure of the jet siphon toilet according to the embodiment of the present invention will be described. figure 1 is a front sectional view showing a jet siphon toilet according to an embodiment of the present invention, figure 2 yes figure 1 top view of image 3 is along figure 1 Sectional view of line III-III.

[0059] Such as Figure 1 to Figure 3 As shown, the jet siphon toilet 10 of the present embodiment includes a toilet body 12 and a water storage tank 14 arranged at the rear upper portion of the toilet body 12 for storing flush water. The water storage tank 14 stores 2.5 liters of 6.5 liters of flushing water.

[0060] The toilet body 12 has a bowl portion 16 at the front portion, and a bowl-shaped dirt receiving surface 18 and an edge portion 20 as an upper edge portion are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com