Print mechanism of flat-panel printer

A flatbed printer and printing mechanism technology, applied in the direction of typewriter, printing, etc., can solve the problems of the structure of the printer cannot be adapted, the response speed of the printer is slow, and it is difficult to move items, and the control response speed is fast, the sliding is stable, and the control is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the utility model is described further.

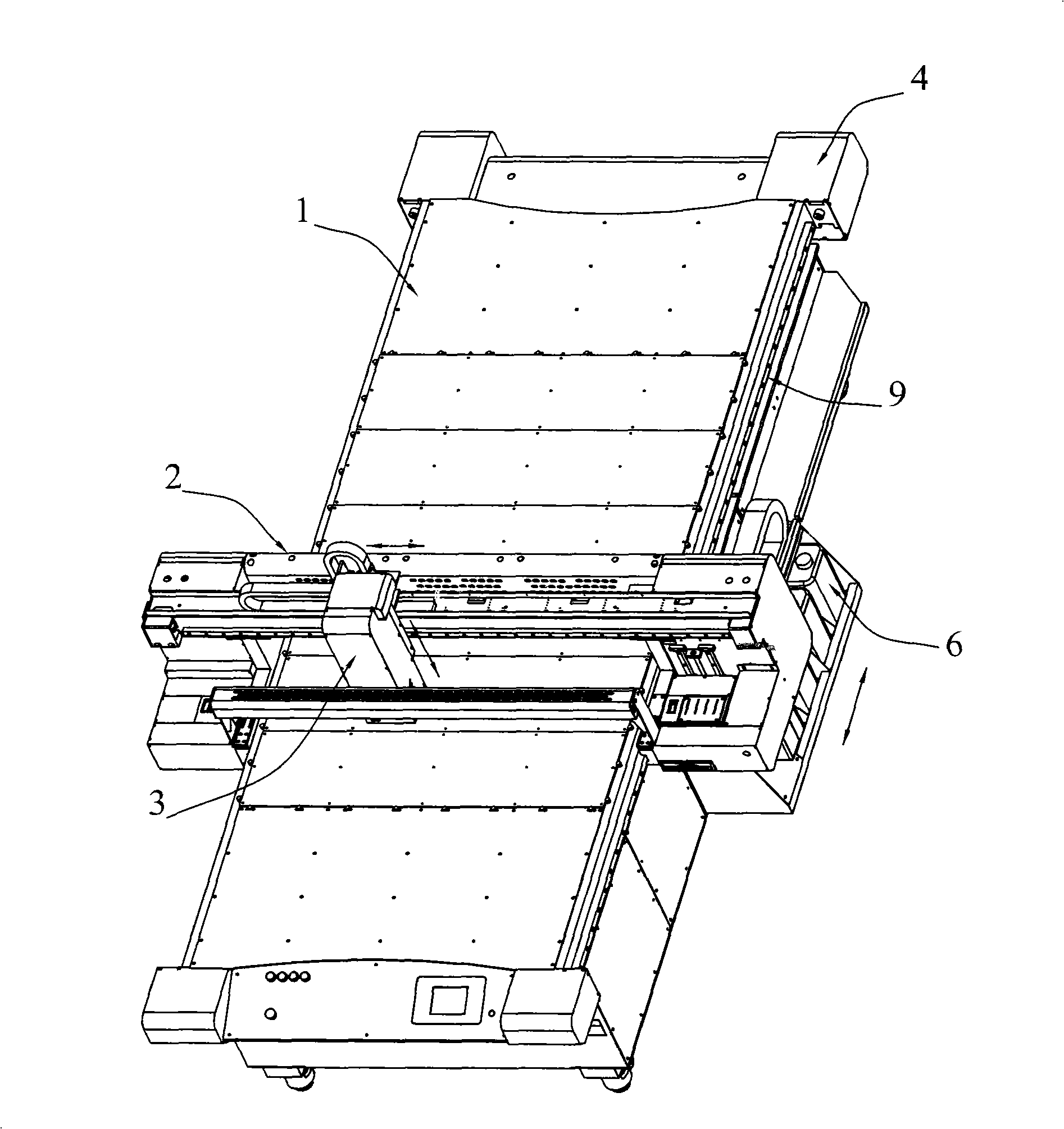

[0022] like figure 1 The large-scale flatbed printer shown has a printing mechanism installed on the printer base 1, the printing mechanism includes a spray car 2 and a print nozzle 3, the upper part of the printer base 1 forms a rectangular support platform, and the spray car 2 is installed on the printer base 1 along the long side direction Sliding back and forth, the print nozzle 3 is installed on the sprayer 2 and slides left and right along the short side of the printer base, and moves up and down in the direction perpendicular to the printer base 1, as shown by the arrow in the figure.

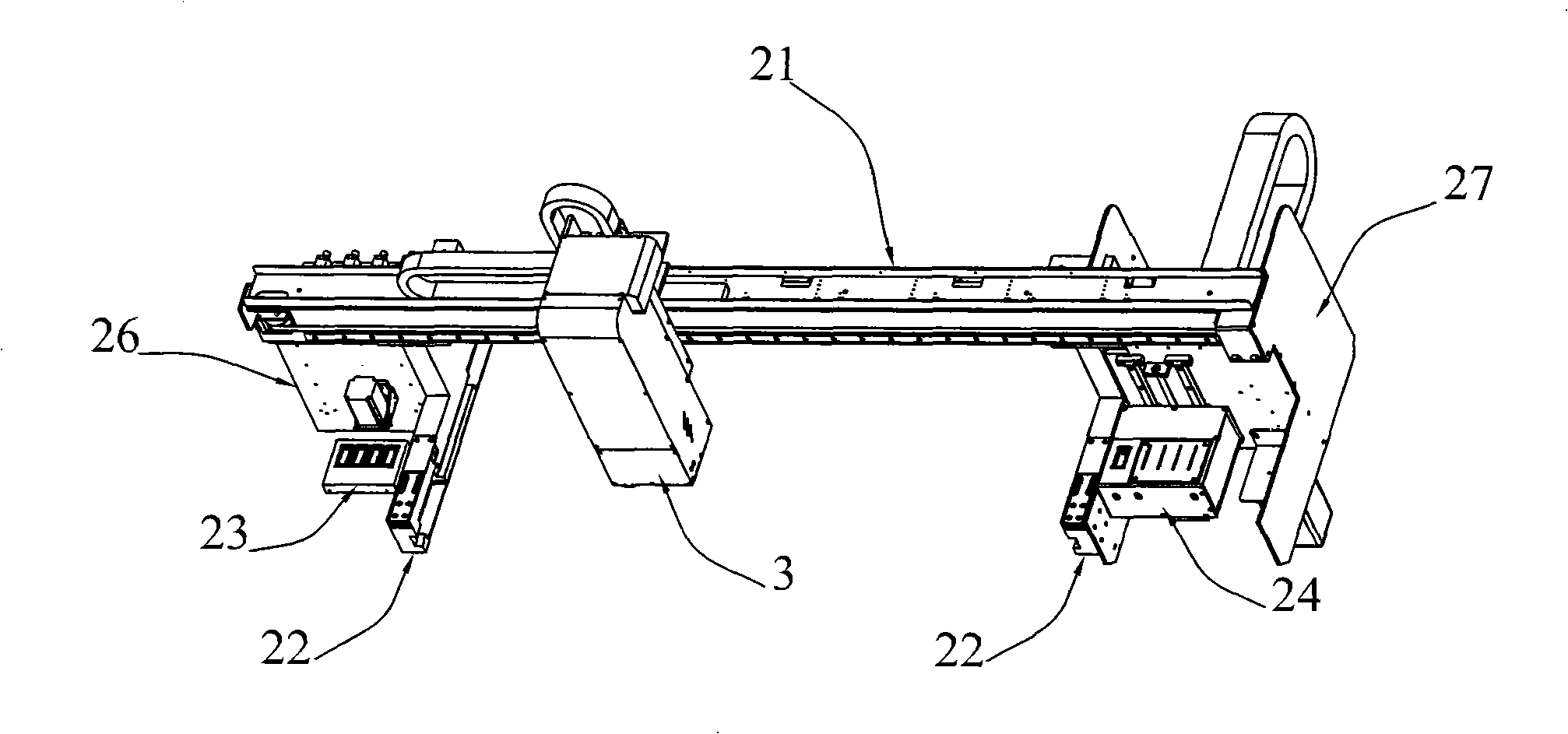

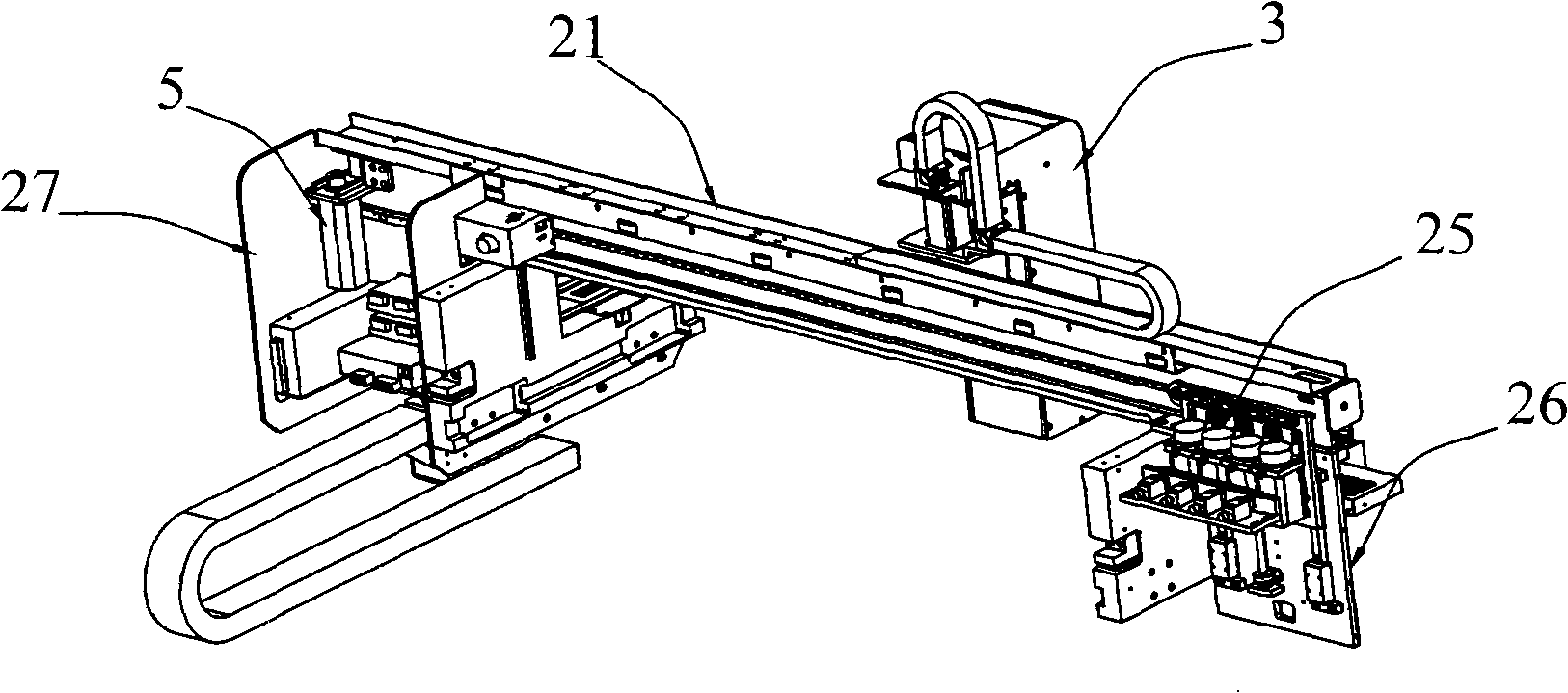

[0023] combine figure 2 and image 3 It can be seen that the spray vehicle 2 is in the shape of a door, with a beam 21 in the middle, and slide seats 26 and 27 supporting the beam 21 at both ends. Slide rail 9 cooperates. The end of the printer base 1 is provided with a gearbox 4 (the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com