Cigarette filter and method of its manufacturing

A technology for filter tips and cigarettes, which is applied to e-liquid filters, tobacco, tobacco processing, etc., can solve the problems of high price, high pressure loss of cigarette filters, and hindering use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

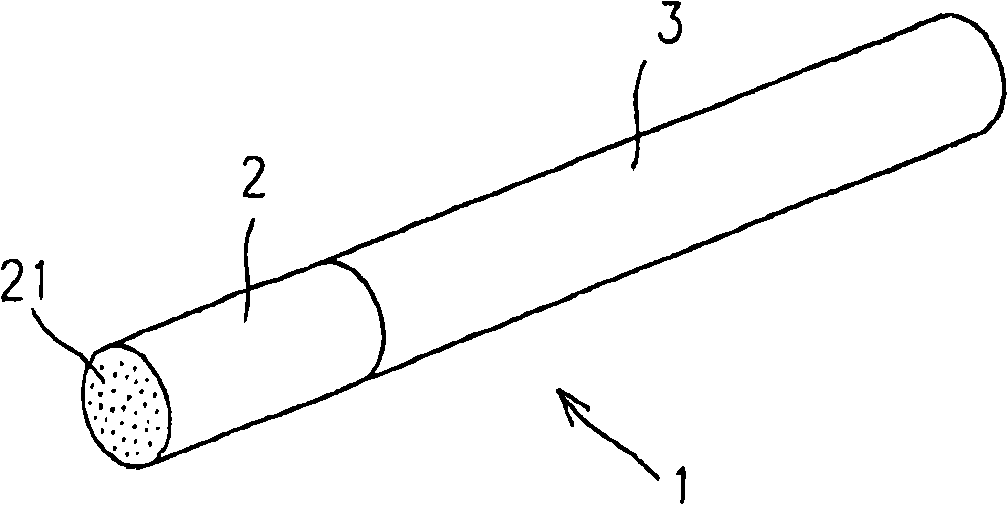

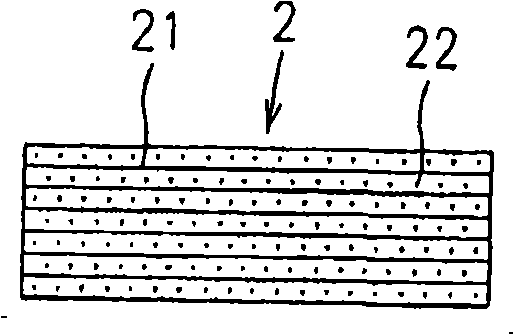

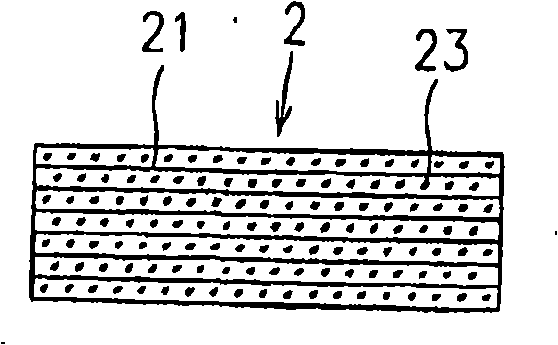

[0027] exist figure 1 In the case of the cigarette 1 shown in , a cigarette filter 2 is manufactured by a tubular body, one face of which is attached to the tobacco tubular part 3 of the cigarette and the second face is the free face. It is known from the background art that the tubular body of a cigarette filter is formed from a fiber cord or a system of fiber cords which are essentially parallel fibers, and finally from a system which is essentially parallel threads or threads, and the fibers, threads or threads which flow through the filter The direction of the smoke is oriented parallel, and they are made of fibers, the diameter of which varies from 1 micrometer to 40 micrometers, and therefore they will be called microfibers 21 subsequently. According to the invention, nanofibers 22 are arranged in these microfibers 21 in amounts of up to 10% by weight. At the same time, it is advantageous to have the nanofibres 22 in the microfibres 21 arranged uniformly throughout the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com