Test device and method for acquiring limit strain of laser tailor welded plate plane with different thickness

A technology of laser tailor welding and ultimate strain, applied in the field of sheet metal forming processing, can solve the problems of large workload, poor stability, inappropriate thickness tailor welded blanks, etc., to achieve simple, easy to operate, accurate and stable test results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

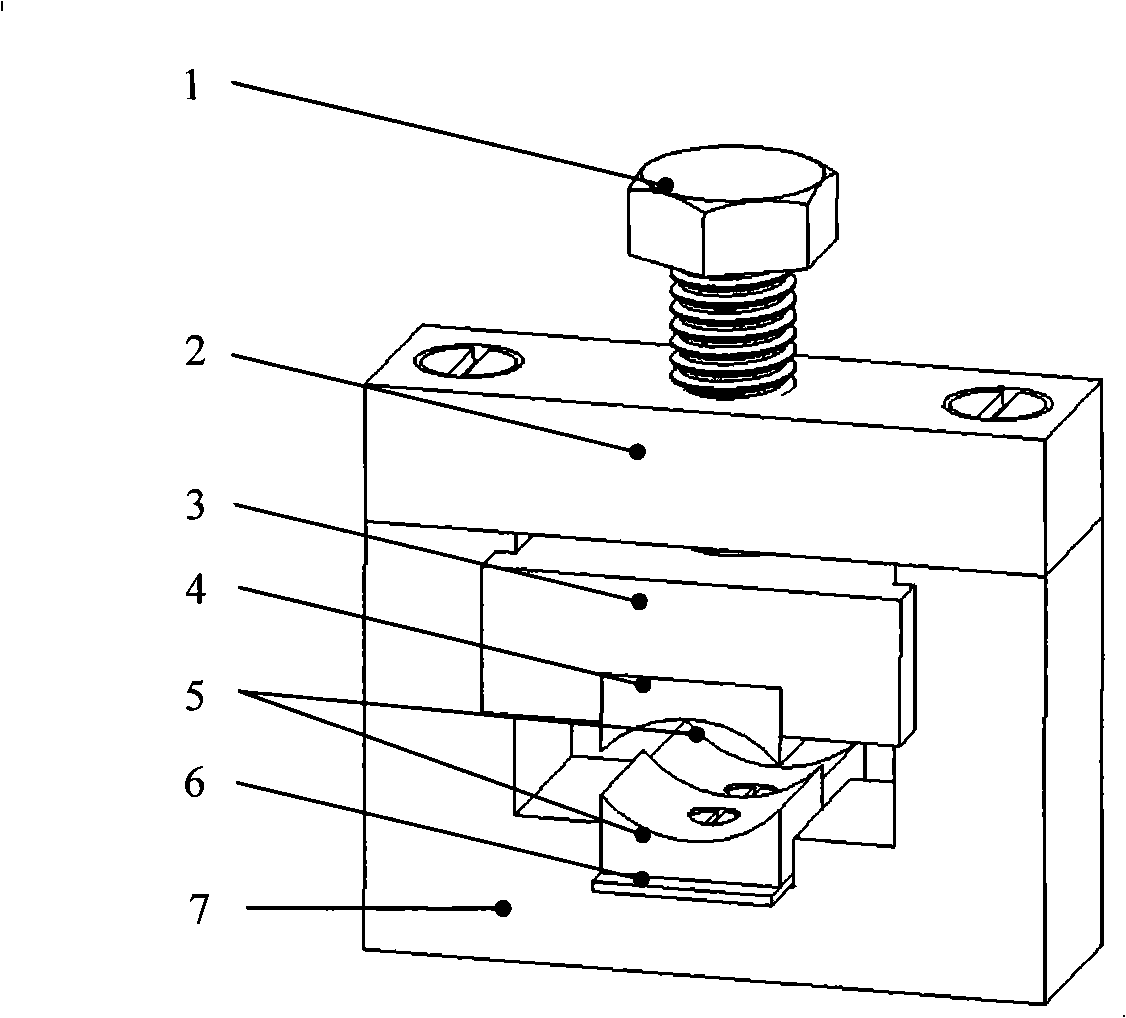

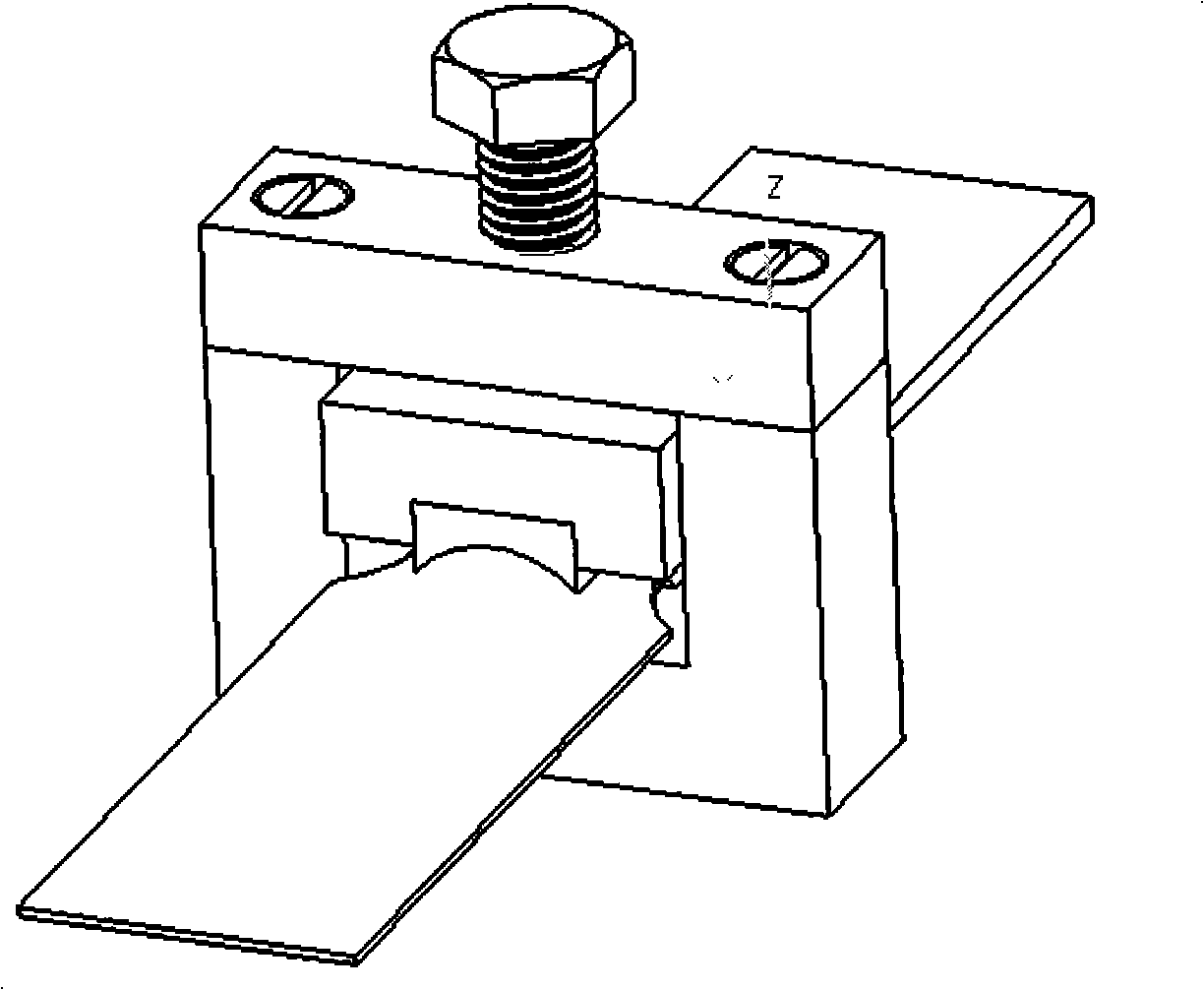

[0030] Figure 1-7 As shown, it is the test device for obtaining plane ultimate strain of laser tailor-welded blanks with different thickness proposed by the present invention, which is mainly composed of splint mechanism, segmented clip height difference structure, clamping mechanism and tailor-welded blank plane strain tensile test piece. The splint mechanism is composed of the upper clip 4 and the segmented lower clip 5, the tailor welded blank tensile test piece 8 is located between the upper clip 4 and the segmented lower clip 5, and the splint mechanism can clamp the tailor welded blank for stretching The test piece 8 effectively restricts its shrinkage in the width direction, and produces a plane strain state in the tailor welded blank tensile test piece 8 . The clip 4 and the slide block 3 are threadedly connected, and a height adjustment piece 6 is installed between the subsection lower clip 5 and the base 7, and the subsection bottom clip 5 and the height adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com