Reciprocating linear motion mechanism

A linear motion, reciprocating technology, used in mechanical equipment, transmission devices, friction transmission devices, etc., can solve the problems of limited stroke, uneven speed, and high requirements for component manufacturing accuracy, and achieve a large stroke range and smooth commutation. , the effect of uniform speed

Inactive Publication Date: 2008-10-29

冯志晶

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These mechanisms have their own advantages and disadvantages. Among them, the fluid transmission mechanism has the advantage of easy reversing, but it needs to install various power components, actuators, control components, auxiliary components and working media, etc., and the components require high manufacturing accuracy; The mechanism also has the advantage of easy reversing, but there are defects such as limited stroke and uneven speed; although the screw-nut mechanism and the rack-and-pinion mechanism run at a uniform speed and have a large stroke, it is necessary to install a reversing device and set a limit switch

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

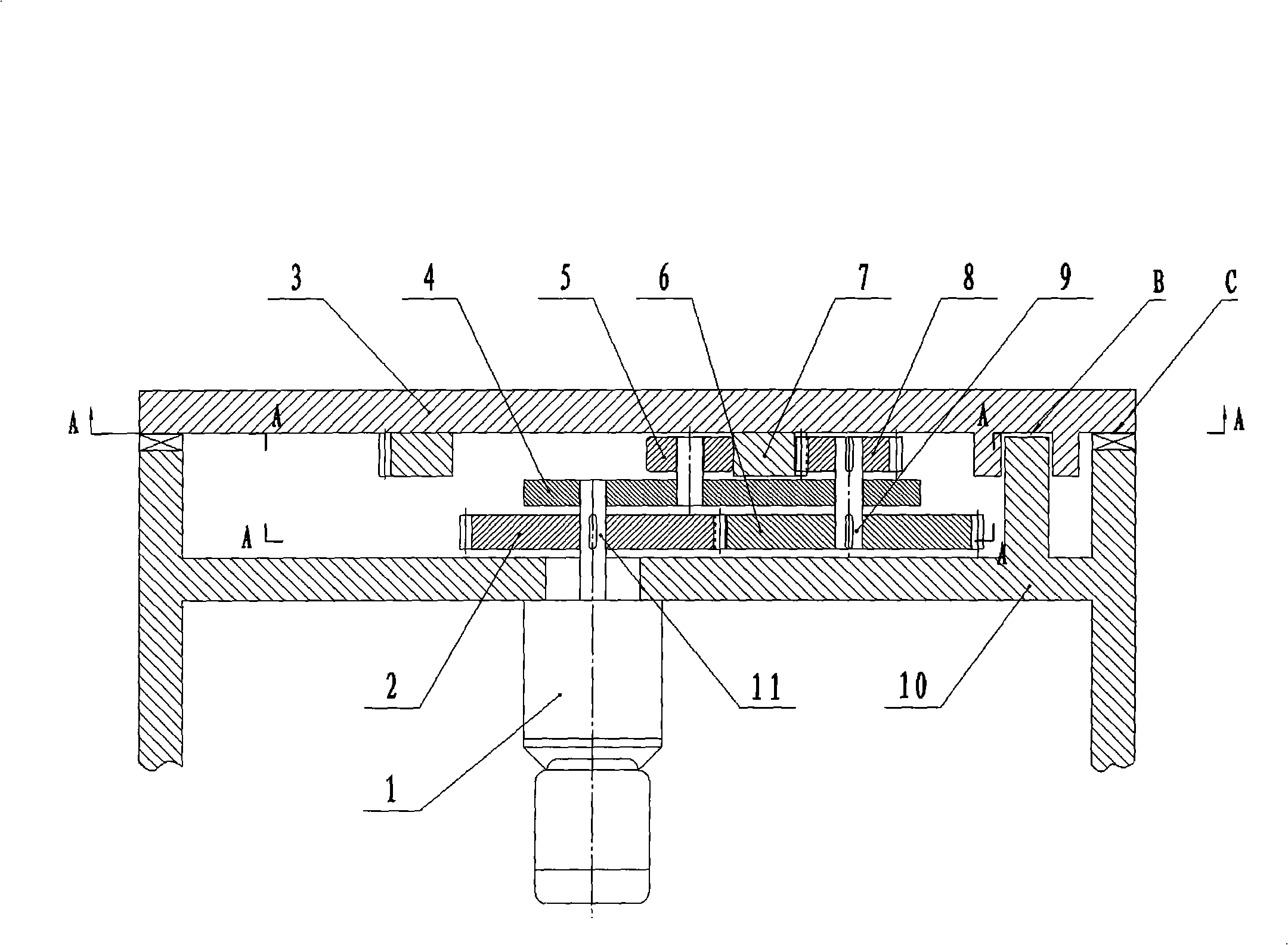

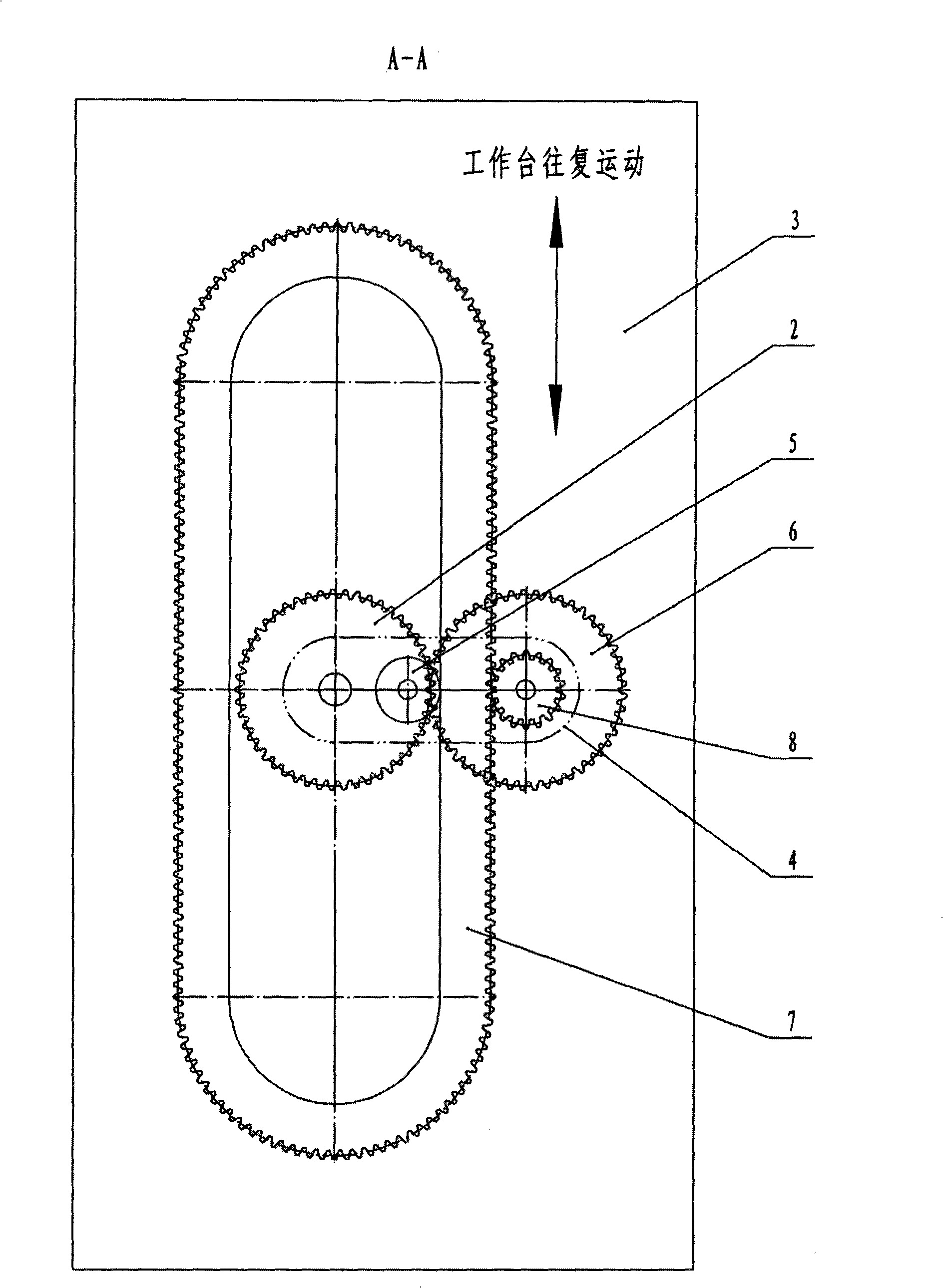

The invention relates to a reciprocating linear motion mechanism. A closed externally-toothed guide rail consists of two toothed racks and two semi-circular externally-toothed rings and is fixed on a work bench with a linear guide rail. A driving gear is fixedly connected with a driving shaft. A wheel axle support frame is connected with the driving shaft, a guide wheel and an intermediate gear shaft. Two intermediate gears are fixedly connected with two ends of the intermediate gear shaft and engages with the external teeth of the driving gear and the closed externally-toothed guide rail respectively. The guide wheel is matched with the internal rail of the closed externally-toothed guide rail. The driving mechanism supplies power to the driving gear via the driving shaft and then to the intermediate gear II via the intermediate gear I and the intermediate gear shaft and acts on the closed externally-toothed guide rail. Under the limitation of the guide wheel, the intermediate gear II makes cyclic motion along the closed externally-toothed guide rail, thereby driving the work bench to make reciprocating linear motion. The mechanism is characterized in large travel range, uniform velocity, smooth turning and no need of limit switch; and is suitable for mechanical equipment in need of uniform-velocity and large-travel reciprocating linear motion.

Description

Reciprocating linear motion mechanism technical field The invention relates to a reciprocating linear motion mechanism, in particular to a reciprocating linear motion mechanism with large stroke range, uniform speed and smooth reversing. Background technique Existing driving modes for realizing reciprocating linear motion generally include the following modes: fluid transmission mode, including hydraulic transmission and pneumatic transmission mechanisms; crank slider mechanism; screw nut mechanism; rack and pinion mechanism. These mechanisms have their own advantages and disadvantages. Among them, the fluid transmission mechanism has the advantage of easy reversing, but it needs to install various power components, actuators, control components, auxiliary components and working media, etc., and the components require high manufacturing accuracy; The mechanism also has the advantage of easy reversing, but there are defects such as limited stroke and uneven speed; although...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16H19/02B23Q1/25

Inventor 冯志晶

Owner 冯志晶

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com