Multi-point temperature measurement method and temperature measurement equipment for down-hole formation

A temperature measurement equipment, multi-point technology, applied in the field of temperature measurement, can solve the problems of large investment, short service life, large measurement error and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

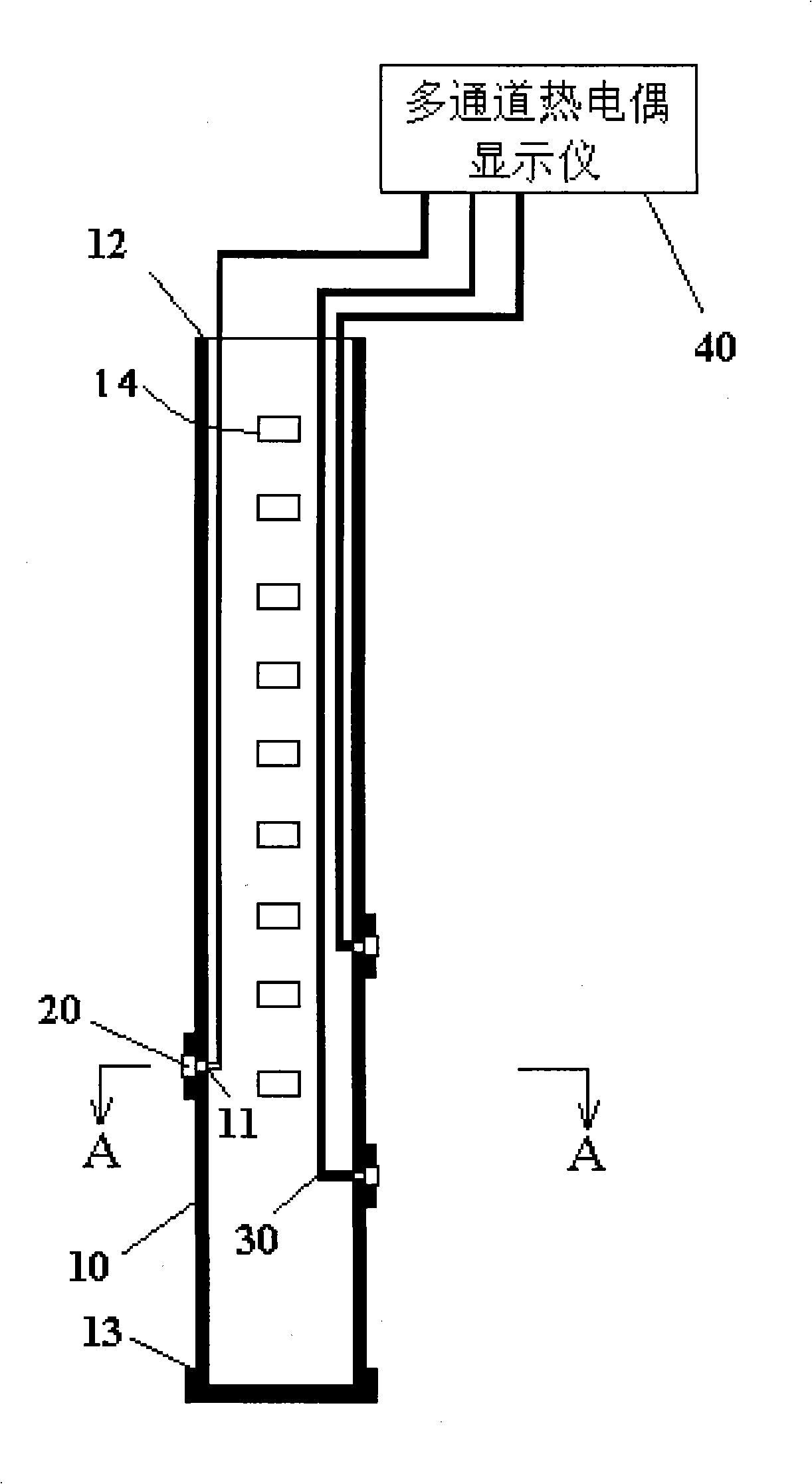

[0022] refer to figure 1 As shown, the underground multi-point temperature measurement equipment of the present invention is mainly composed of four parts: a protection tube 10 , an armored thermocouple 20 , a compensation line 30 and a multi-channel temperature measurement display instrument 40 . in:

[0023] The protection tube 10 is a hollow structure, which can accommodate the compensation line 30 inside. The nozzle 12 at one end of the protection tube 10 is not closed for the compensation line 30 to pass through, and the nozzle 13 at the other end is blocked and extended into the well; The tube wall of the protective tube 10 is provided with a plurality of fixing holes 11 at intervals along the axial direction of the tube.

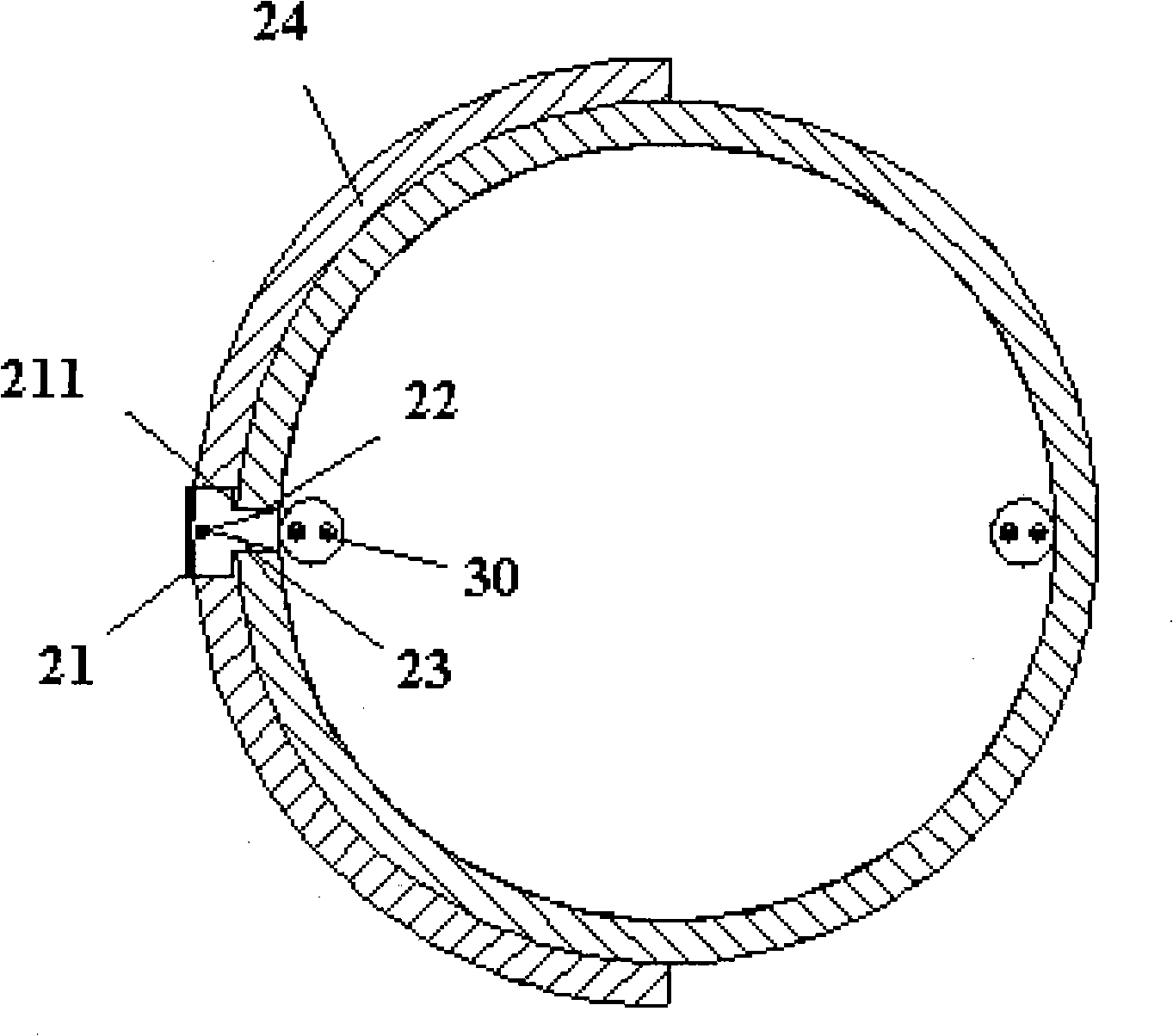

[0024] Another example figure 2 As shown, the armored thermocouple 20 includes a metal shell 21, and the outer diameter of one end of the metal shell 21 is enlarged to form a limiter 211, so that the shell 21 is stepped as a whole, and the limiter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com