Method for discharging boat to dock basin with dock yard trestle crane set

A technology of gantry cranes and docks, which is applied in the field of fast unloading of complete gantry cranes in shipyards to docks. It can solve problems such as poor safety, labor, material and time consumption, and large space occupation, and achieve fast and accurate positioning and alignment. The effect of fast and saving dock space

Active Publication Date: 2008-10-29

SHANGHAI ZHENHUA HEAVY IND

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The task of the present invention is to provide a method for unloading a ship from a complete gantry crane in a shipyard to a dock, which solves the problems that the traditional on-site assembly occupies a large space, consumes manpower, material resources and time, has poor safety, and affects the operation of the shipyard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

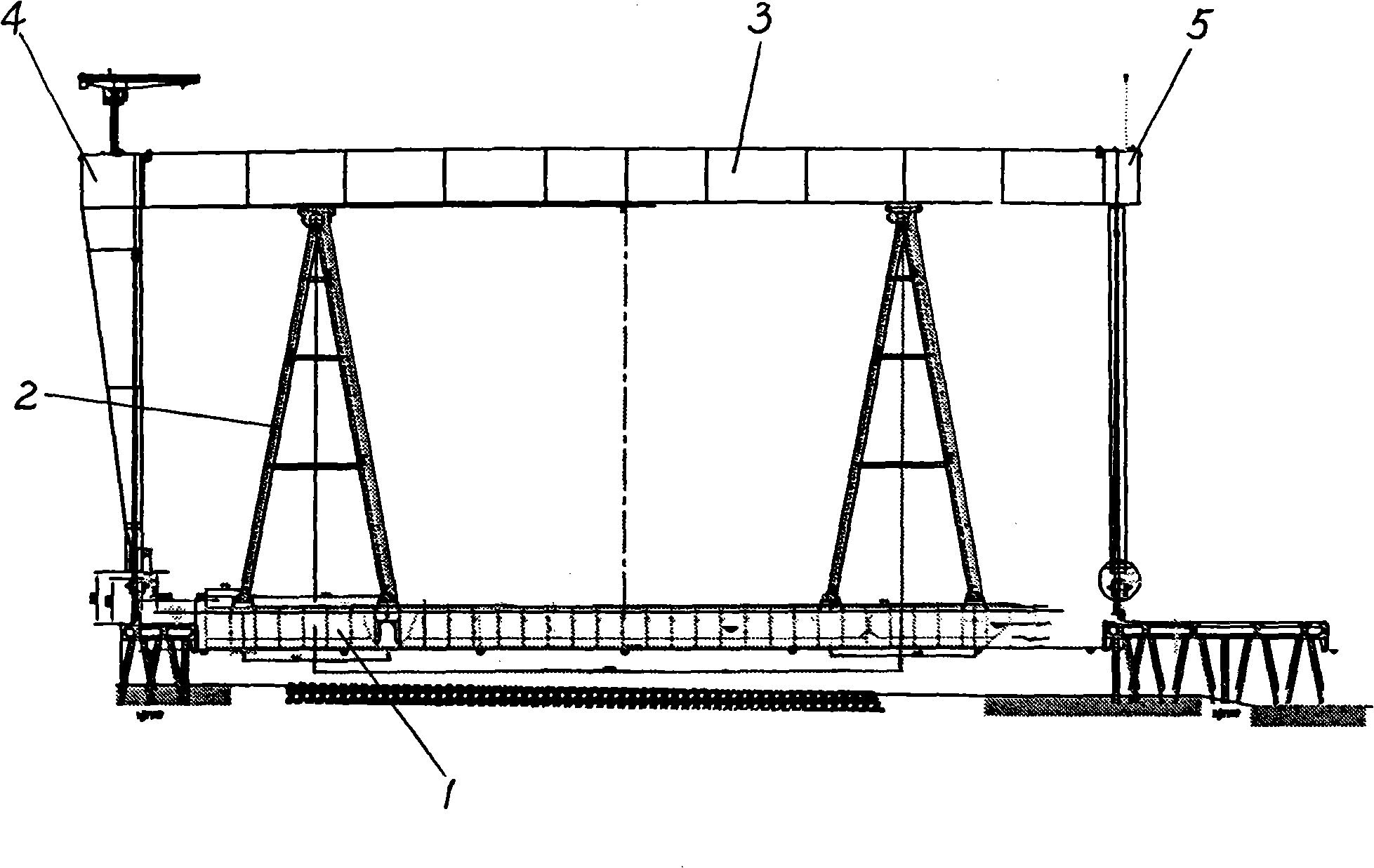

The invention relates to a method, by which a shipyard gantry crane is wholly unloaded to a dock. A deck barge and a hoister are used for installing the shipyard gantry crane onto two tower frames; a rigid leg side tower frame and a main beam are fixedly connected with each other; a flexible leg side tower frame and the main beam are designed as a release-typed fixing type in the track direction of a dolly; the deck barge is delivered to the front end harbour of the user dock by a tugboat; the position of the barge is adjusted, so as to lead the flange surfaces of the rigid leg and the flexible leg to be exactly butted to the flange surfaces of the gantry of the container crane which is assembled at the user dock in advance; during the tidal stand of the river and sea water, the barge cabin is pressed by water; a guide pin is firstly used for guiding and a pivoting bolt is used for positioning; bolts beside the rigid leg are then mounted; meanwhile, the side of the flexible leg is adjusted; the guide pin is used for guiding so as to mount the bolts after the bolt holes are positioned; during the ebb of the river and sea water, the barge gradually falls with the tidewater and is disengaged to the gantry crane structure; the whole gantry crane is unloaded to the dock; therefore, the method of the invention has the advantages of safety, reliability, fastness, convenience, saving labour, saving time and saving dock sites.

Description

The method of unloading the whole machine of the gantry crane in the shipyard to the dock technical field The invention relates to a gantry crane, in particular to a method for quickly unloading a complete gantry crane in a shipyard to a dock. Background technique Nowadays, the trend of large-scale development of ships is rapid, and the docks are also being built larger and larger, and the span and height of the supporting dock gantry cranes are also increasing. Due to the large size and weight of such large-scale gantry cranes, the traditional method is Manufactured in sections in the factory, transported to the dock of the shipyard, assembled into components in sections, and then assembled on-site in the dock one by one using the single-horned gantry or double gantry, and using the cable lifting method. From component assembly to hoisting of a gantry crane, it takes at least three months for the final assembly of the on-site tower in the dock. Since the on-site assembly ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65G67/60

Inventor 黄红雨张明海余华宝严冬华

Owner SHANGHAI ZHENHUA HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com