Precooling apparatus of plastic tube product line

A plastic pipe and production line technology, which is applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve problems such as difficult to achieve glossy effect, achieve the effects of reducing heat transfer, improving plasticizing effect, and improving product quality

Inactive Publication Date: 2010-12-01

福建祥龙塑胶有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing method can only be improved by controlling the raw material formula and production process, so the appearance of the pipes produced in this way can basically only achieve matt brightness, and it is difficult to achieve a good gloss effect like a mirror surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

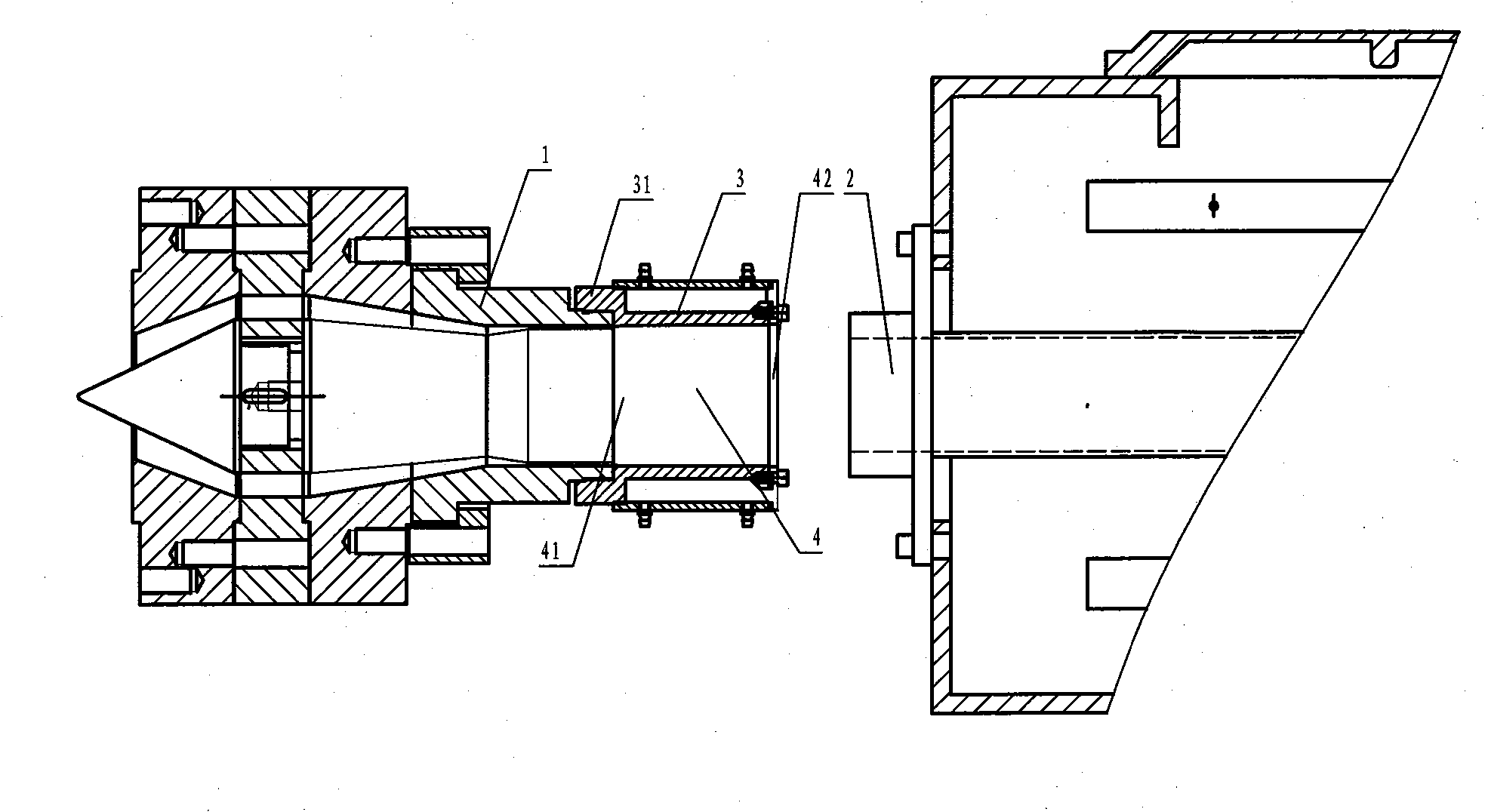

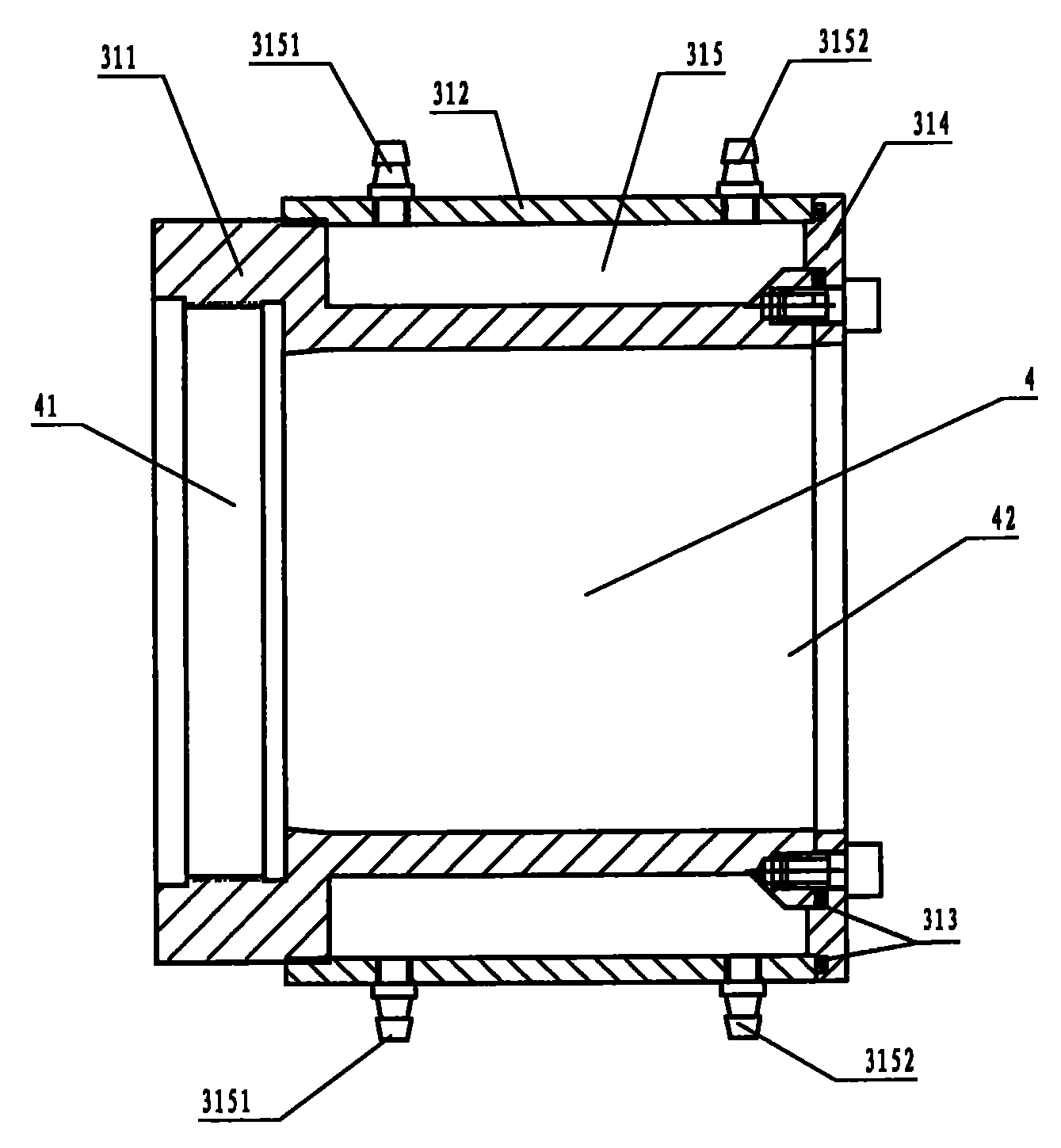

The invention discloses a pre-cooling device of a plastic tubular product manufacture line, which includes a shell with a sandwich; the inlet end of a material circulating channel in the inner cavity of the shell is communicated with the material outlet of a handpiece finish mold; the outlet end is communicated with the inlet of a sizing sleeve; the two ends of the sandwich of the shell are closed; the sandwich of the shell and the two end surfaces of the sandwich form the refrigerating channel of the pre-cooling device; a refrigerant inlet on the refrigerating channel is arranged on the refrigerating channel near the end of the handpiece finish mold; the outlet is arranged on the refrigerating channel near the end of the sizing sleeve. The pre-cooling device of the invention has the advantages that a high temperature material blank extruded from the handpiece finish mold is cooled by the pre-cooling device of the plastic tubular product manufacture line; therefore, the temperature ofthe extruded material blank is reduced and the material blank is contracted; the outer diameter of the material blank is almost consistent with the inner diameter of the sizing sleeve, thus being easier to enter the sizing sleeve, reducing the heat transferring action between the material blank and the sizing sleeve and avoiding the problems of over-heating of the sizing sleeve and blocking of the material blank from happening; thereby effectively improving the manufacture speed of the plastic tubular product manufacture line and stabilizing the manufacture.

Description

Pre-cooling device of plastic pipe production line Technical field The invention relates to a plastic pipe production line, in particular to a pre-cooling device for a plastic pipe production line. Background technique The existing plastic pipe production line is mainly composed of a blanking device, an extruder, a die head, a sizing sleeve device, a vacuum box, a tractor, a cutting machine and other equipment. The molding of the plastic pipe is mainly formed by extrusion of the die head The cylindrical blank is cooled and vacuumed through the sizing sleeve, so that the cylindrical blank is cooled and shaped to meet the specified size requirements. In this type of assembly line, the blanks are directly entered into the sizing sleeve for cooling and sizing after the exit mold. Because the temperature of the blanks of the just-exit mold is generally about 200 degrees, and the export mold blanks have a certain degree of expansion, so often It will cause the sizing sleeve to heat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C47/00B29C47/90B29K101/00B29L23/00B29C48/90

Inventor 姚忠亮李基安林振宇林聪龙戴永顺李国民柯善林

Owner 福建祥龙塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com