Assembling jig for acceptor and pilot valve body in electro-hydraulic servo valve and method thereof

A technology of electro-hydraulic servo valves and assembly fixtures, which is applied in the direction of manufacturing tools, workpiece clamping devices, metal processing, etc., can solve the problems of low assembly quality, large gap in technical level, poor operability, etc., and achieve good assembly quality and use Long life and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

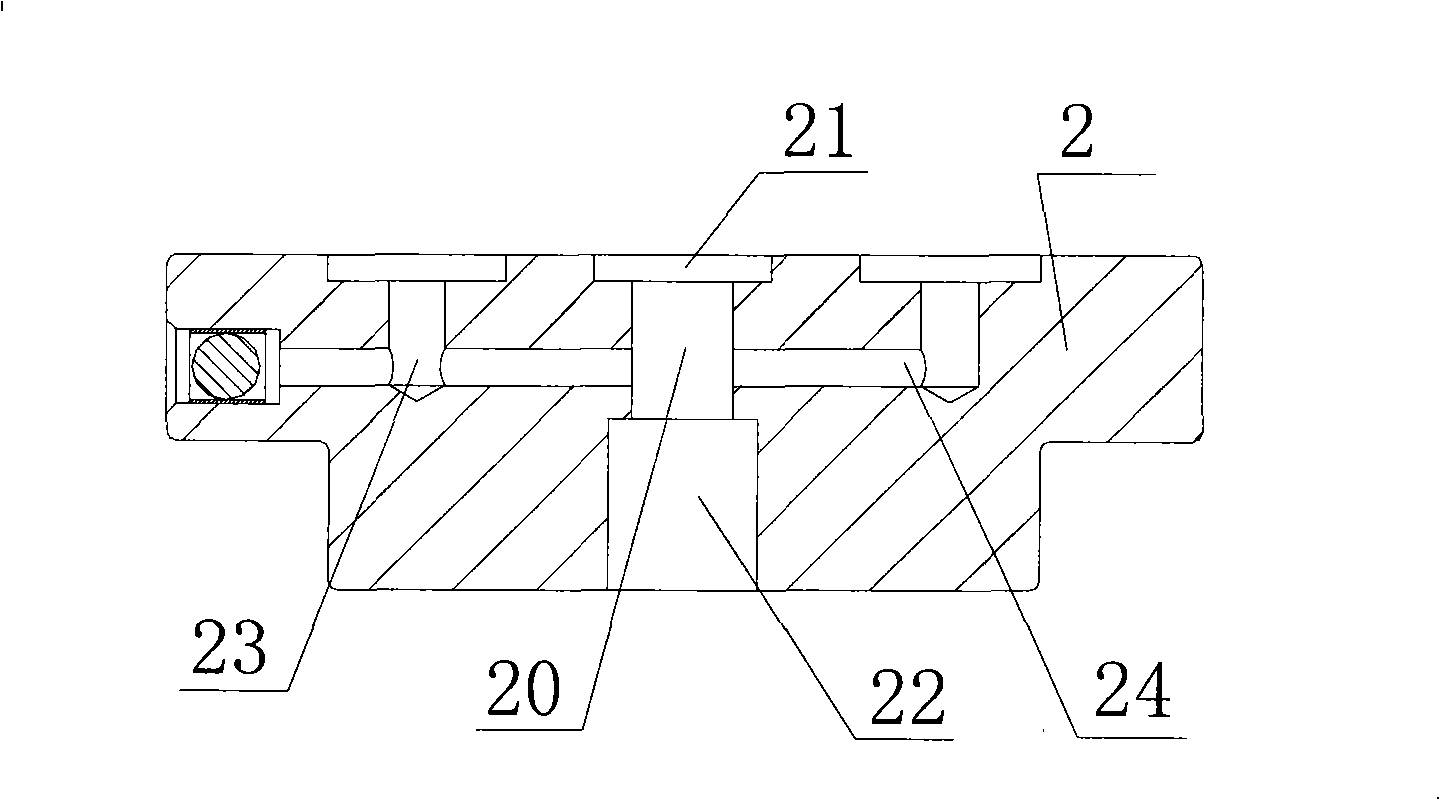

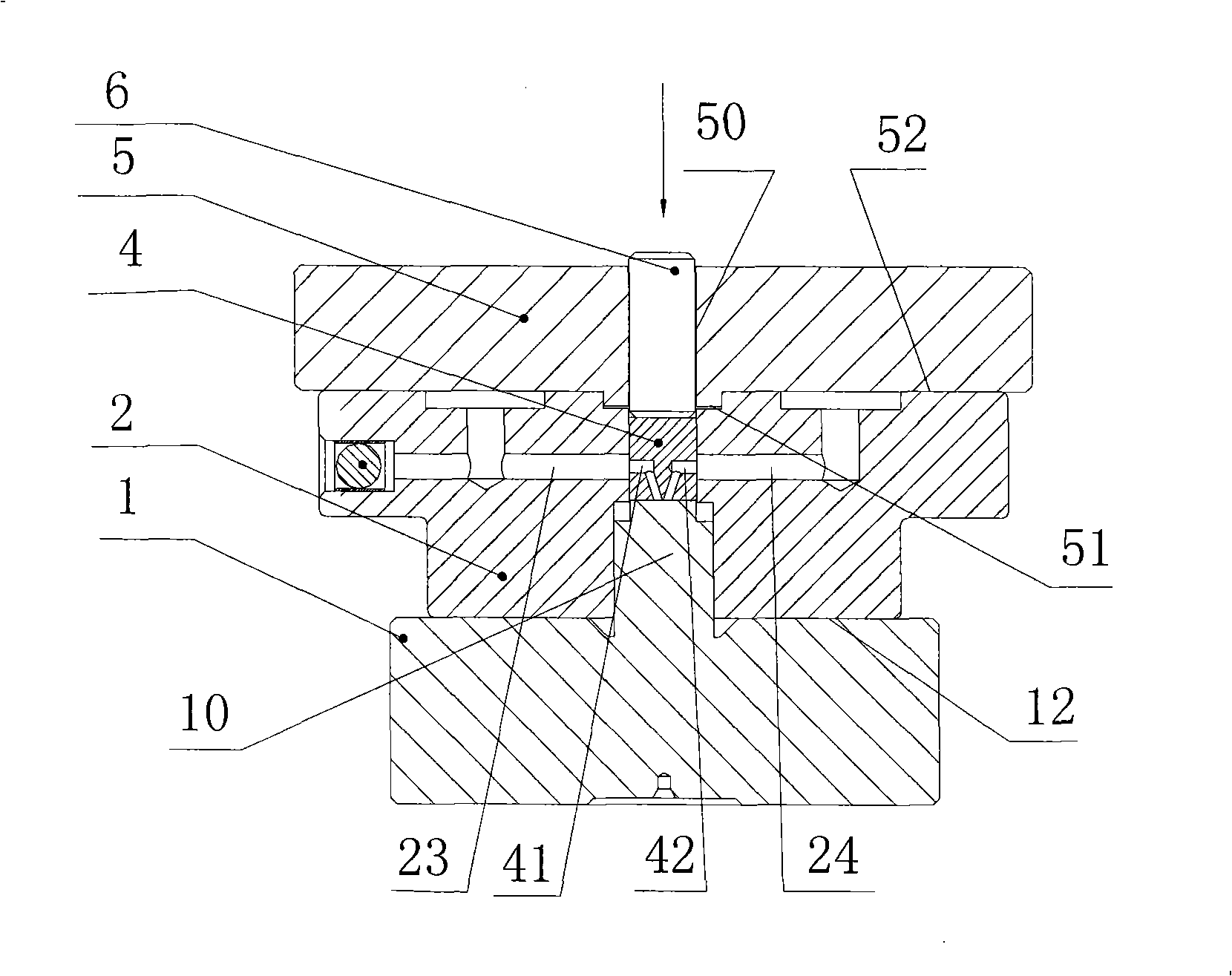

[0013] see figure 1 , figure 2 , the assembly fixture used for the receiver and the pilot valve body in the electro-hydraulic servo valve of the present invention includes an upper positioning block 5, a lower positioning block 1, a pilot valve body 2 and a pressure rod 6. Wherein, the pilot valve body 2 has upper and lower assembly holes 21 , 22 and a receiver cavity 20 , and the receiver cavity 20 has a flat surface opposite to the reference surface of the receiver 4 . The lower positioning block 1 is an inverted T-shaped block, and the shape of the outer end of its vertical rod 10 matches that of the lower assembly hole 22 of the pilot valve body 2 . The upper positioning block 5 is a block body, and the center of its end face is provided with a press-fit through hole 50 consistent with the diameter of the outer end of the receiver 4, and a positioning boss 51 that can be embedded in the assembly hole 21 of the pilot valve body 2 is provided on the lower end face. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com