V shaped seedling needle

A seedling needle and needle point technology, which is applied in the fields of application, agriculture, planting methods, etc., can solve the problems of difficult to meet, tearing of cutting seedlings, etc., and achieve the effect of reducing tearing and cutting neatly and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

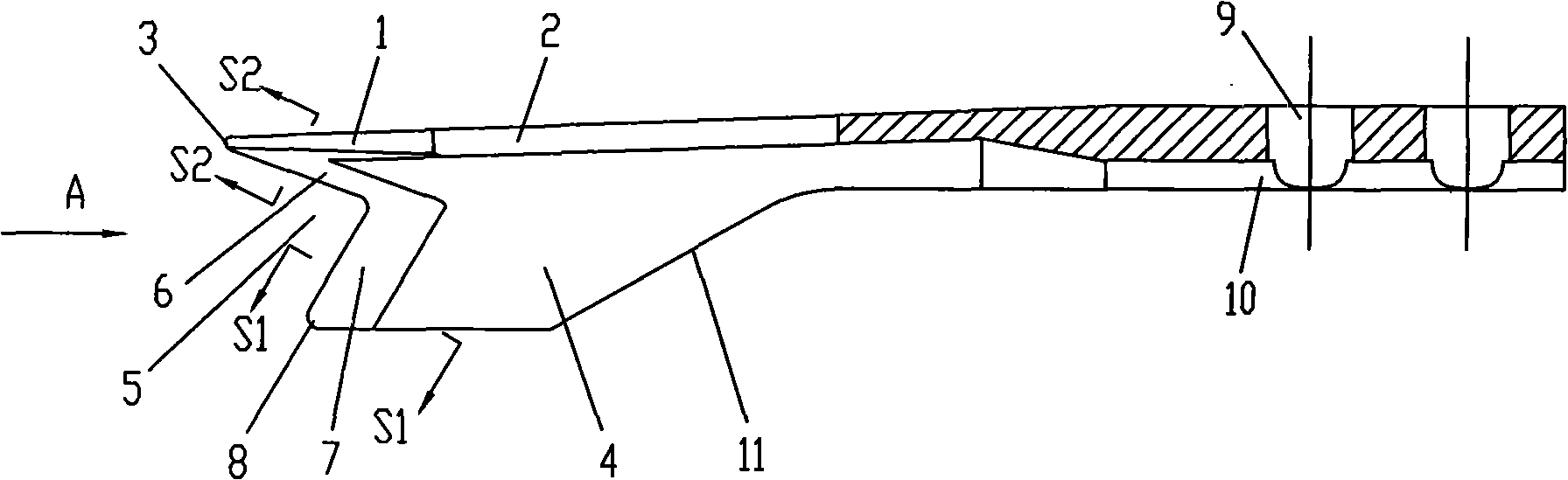

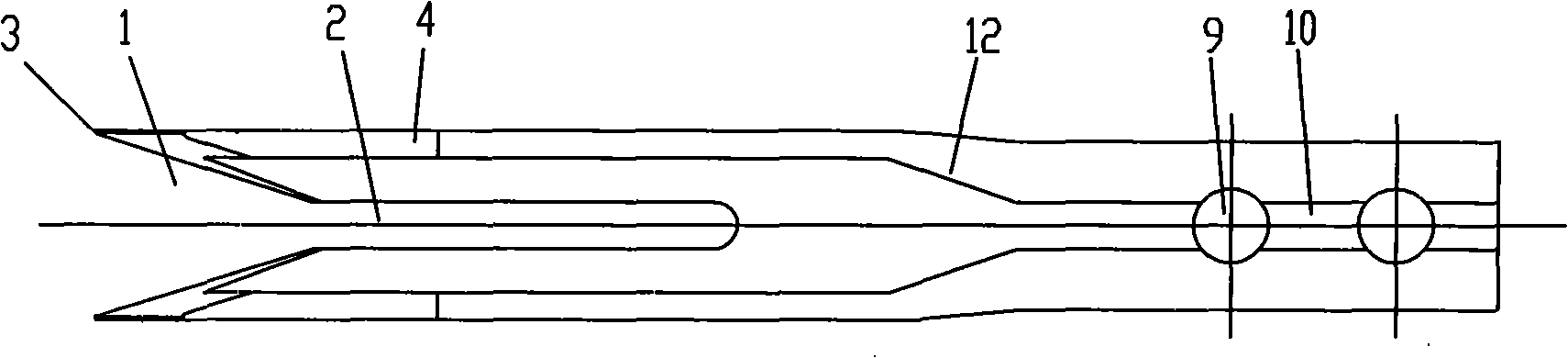

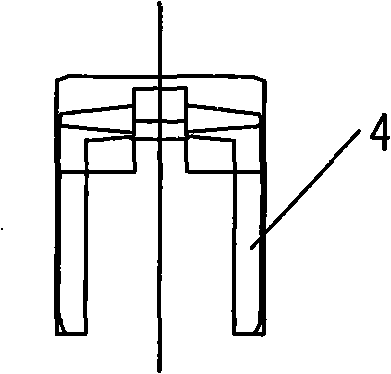

[0016] The V-shaped seedling needle of this embodiment is shown in Figures 1 to 3, one end of the seedling needle body is a needle handle with two mounting holes 9 and the other end is a cutting section. The front end of the cutting section is provided with a horizontal V-shaped notch 1 which communicates with a straight groove 2 extending to the middle of the main body to form a symmetrical left and right cutting section with left and right needle tips 3 respectively. The outer sides of the left and right cutting sections are respectively formed with downward vertical folds 4. A vertical V-shaped recess 5 is formed at the front end of the vertical fold. The side of the V-shaped recess adjacent to the needle tip forms a main cutting edge 6 extending to the needle point. The side of the V-shaped recess away from the needle tip forms a vertical fold. The secondary cutting edge of the lower edge 7. The intersection of the lower edge of the vertical flange and the secondary cutting ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com