Five freedoms turbine blade series-parallel repair robot

A water turbine and degree of freedom technology, applied in the field of repair robots, can solve problems such as difficult repair work, difficult to achieve, poor working conditions and environment, and achieve good economic benefits, ensure repair quality, and shorten the cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

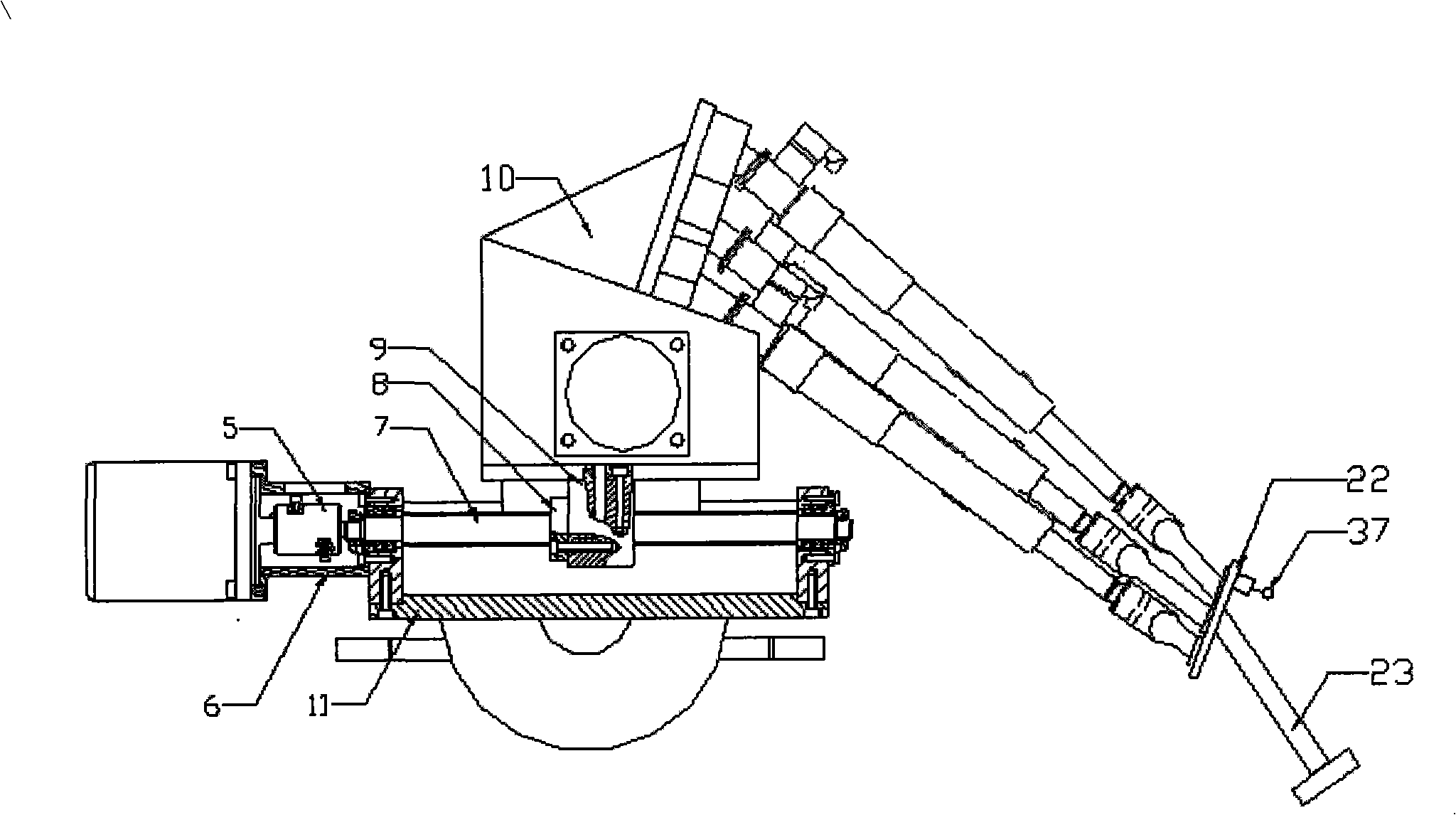

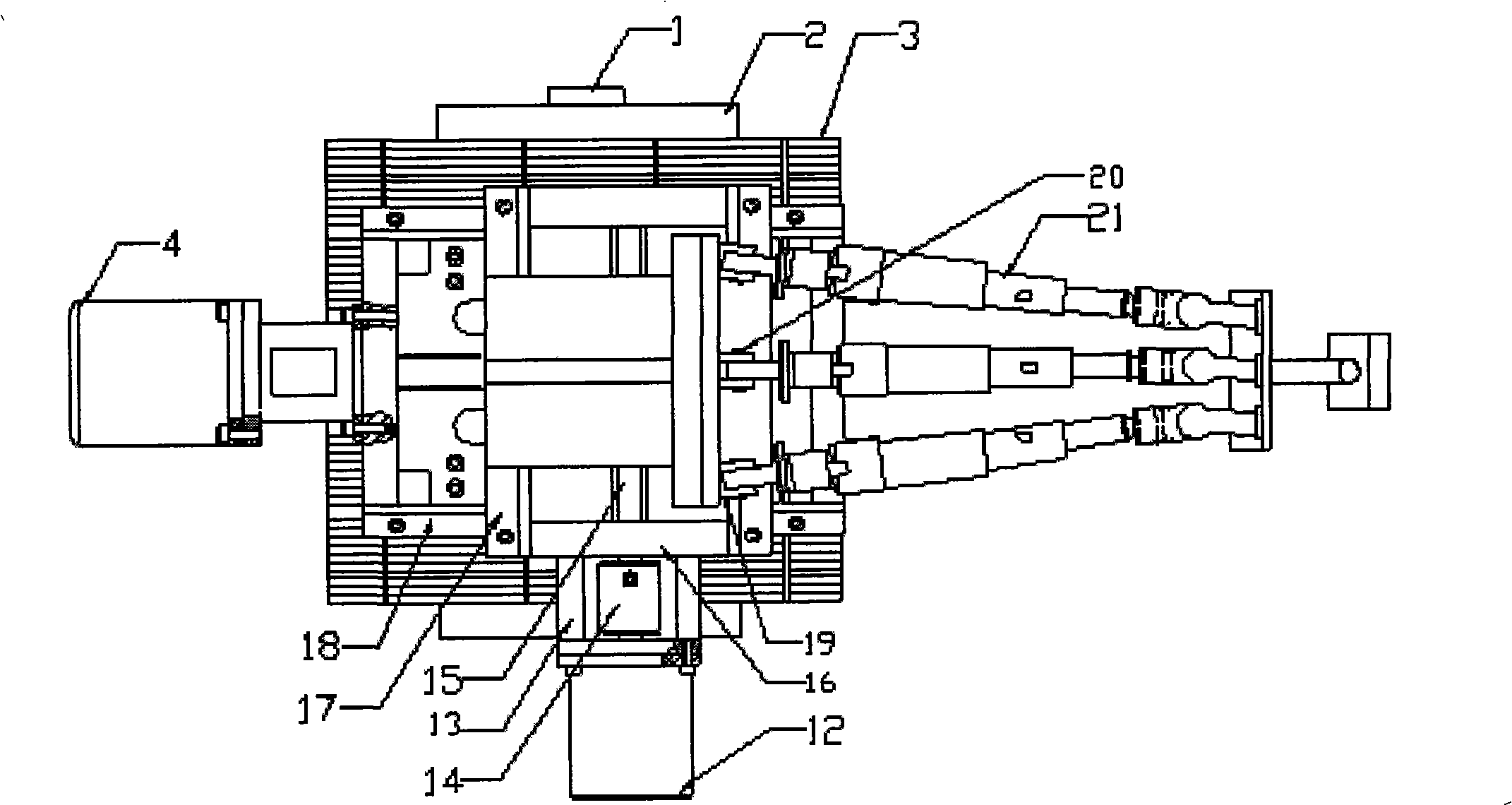

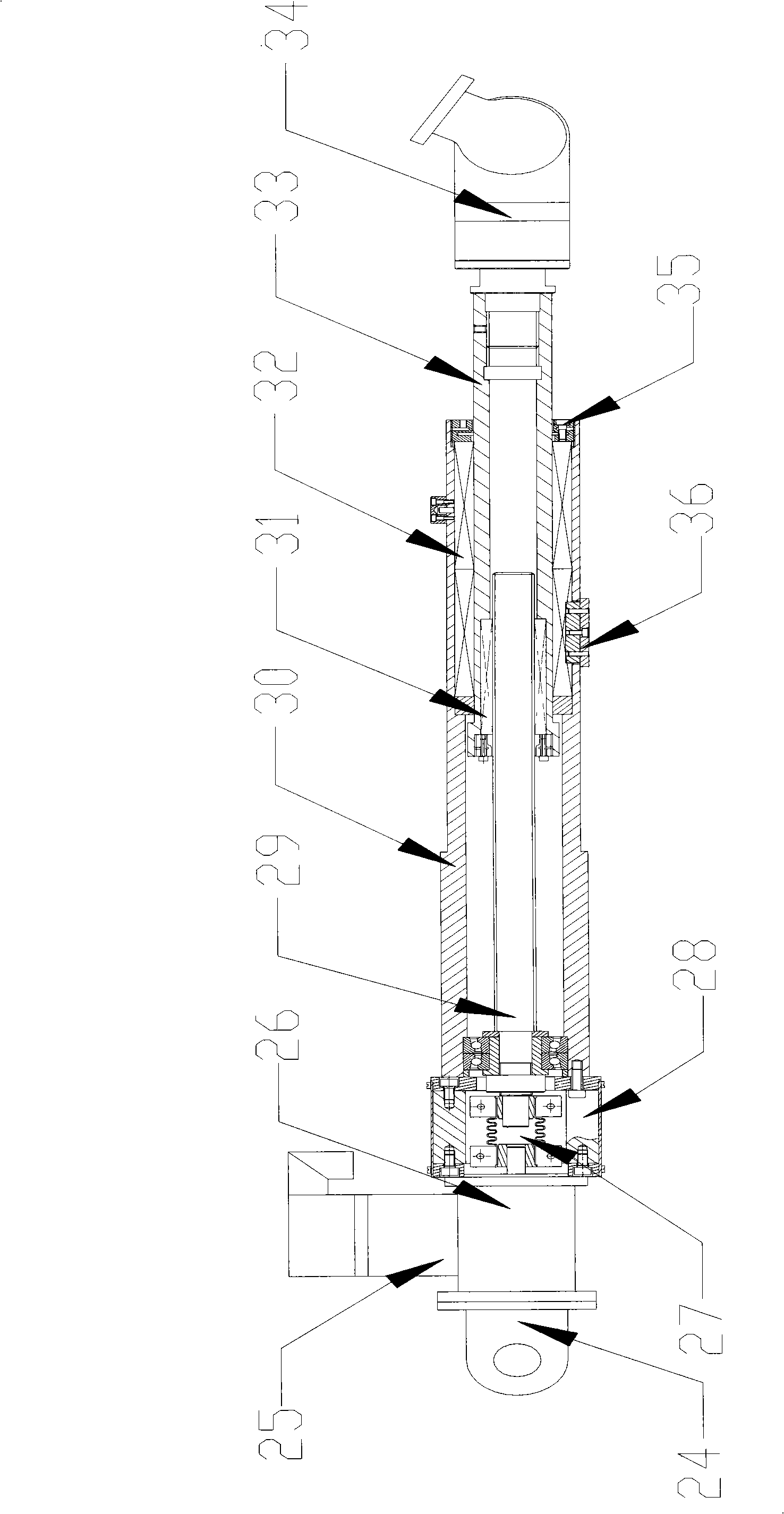

[0017] combine Figure 1 to Figure 3 , the five-degree-of-freedom turbine blade series-parallel repair robot consists of a trolley and a series-parallel robot. The trolley is mainly composed of: travel wheel torque motor 1, travel wheel 2, and electromagnetic board 3. The robot is mainly composed of: transverse motor 4, transverse motor coupling 5, transverse motor connecting plate 6, transverse ball screw 7, transverse screw nut 8, connecting body 9, parallel fixed platform 10, transverse moving bracket 11, and longitudinal motor 12 , Longitudinal motor connecting plate 13, longitudinal motor coupling 14, longitudinal ball screw pair 15, longitudinal moving bracket 16, longitudinal guide rail pair 17, transverse guide rail pair 18, fixed platform hinge seat 19, hinge seat round pin 20, parallel link 21. Parallel linkage platform 22, working tool 23, hinge seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com