Floating guiding hydraulic cylinder

A floating guide, hydraulic cylinder technology, applied in the direction of fluid pressure actuation devices, etc., to achieve the effect of reducing machining accuracy requirements, reducing wear and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

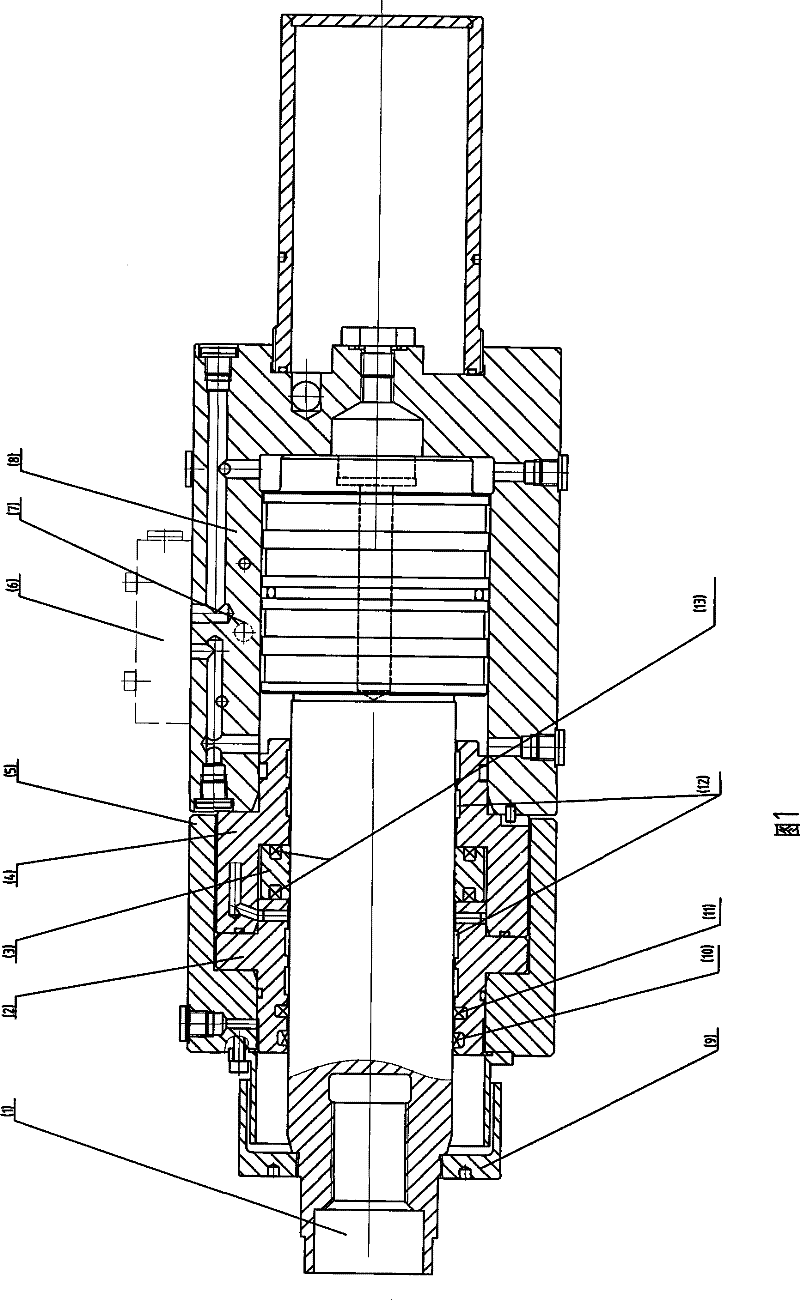

[0016] figure 1 Instructions marked in the middle: piston rod 1, left cylinder liner 2, floating sleeve 3, right cylinder liner 4, front gland 5, hydraulic control valve 6, external oil circuit 7, cylinder barrel 8, protective cover 9, dustproof ring 10 , Sealing ring 11, guide ring 12, floating sleeve sealing ring 13.

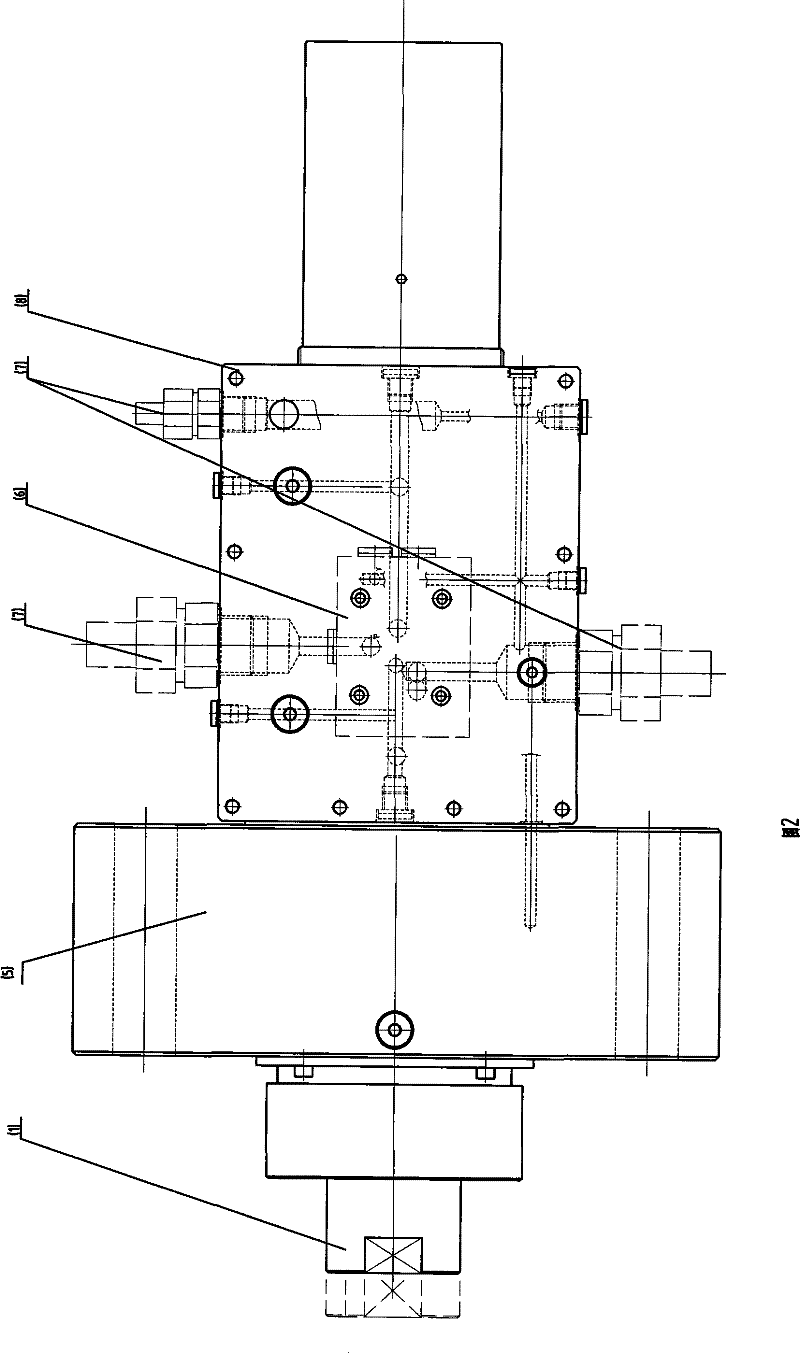

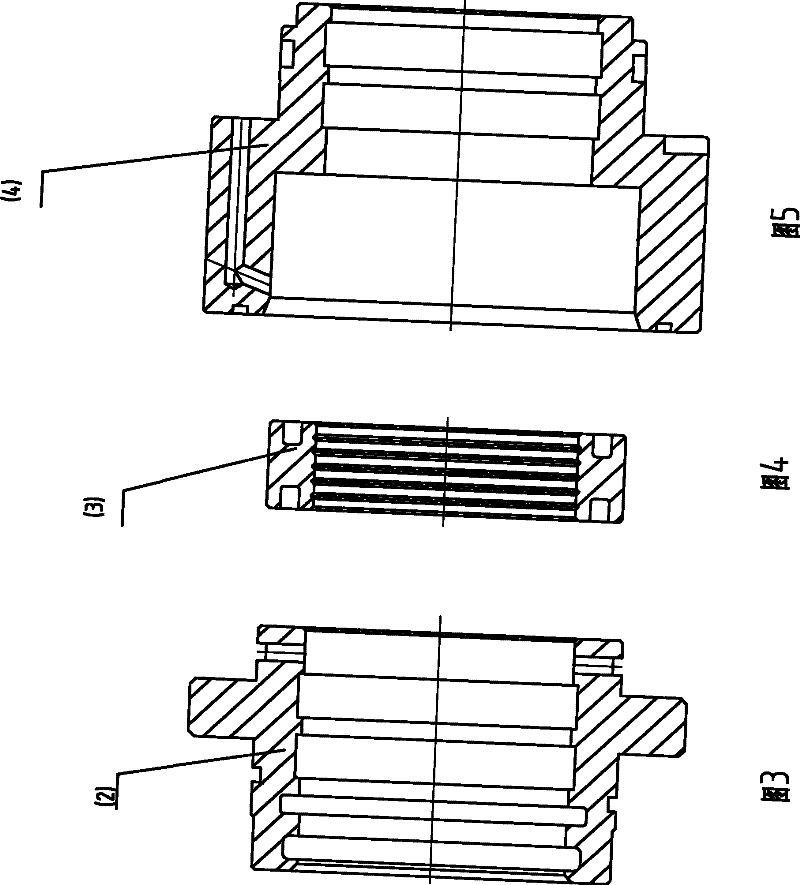

[0017] Examples of the present invention are Figure 1 to Figure 5 shown.

[0018] see figure 1 , the embodiment of the present invention floating guide hydraulic cylinder, including piston rod 1, front gland 5, hydraulic control valve 6, external oil circuit 7, cylinder 8, sealing ring 11, guide ring 12, is characterized in that: the hydraulic cylinder The cylinder liner is composed of the left cylinder liner 2, the floating liner 3 and the right liner 4 which are set on the outer surface of the piston rod 1. The floati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com