Foaming gun

A foaming gun and gun body technology, applied in the direction of construction, building structure, etc., can solve the problems of increasing cost, wear of liquid nozzle, difficult to clean, etc., to improve foaming quantity and quality, prolong service life, improve durability abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

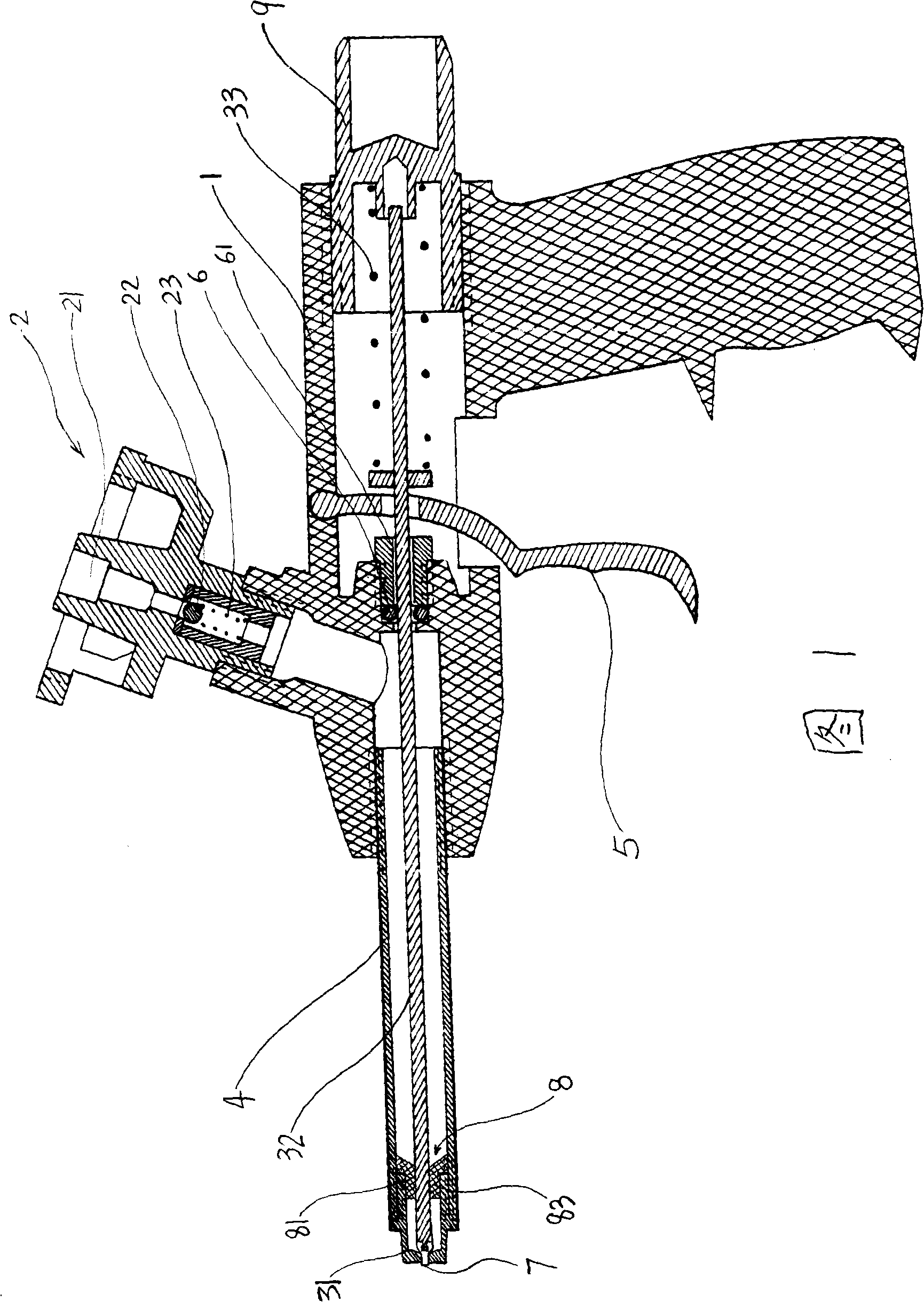

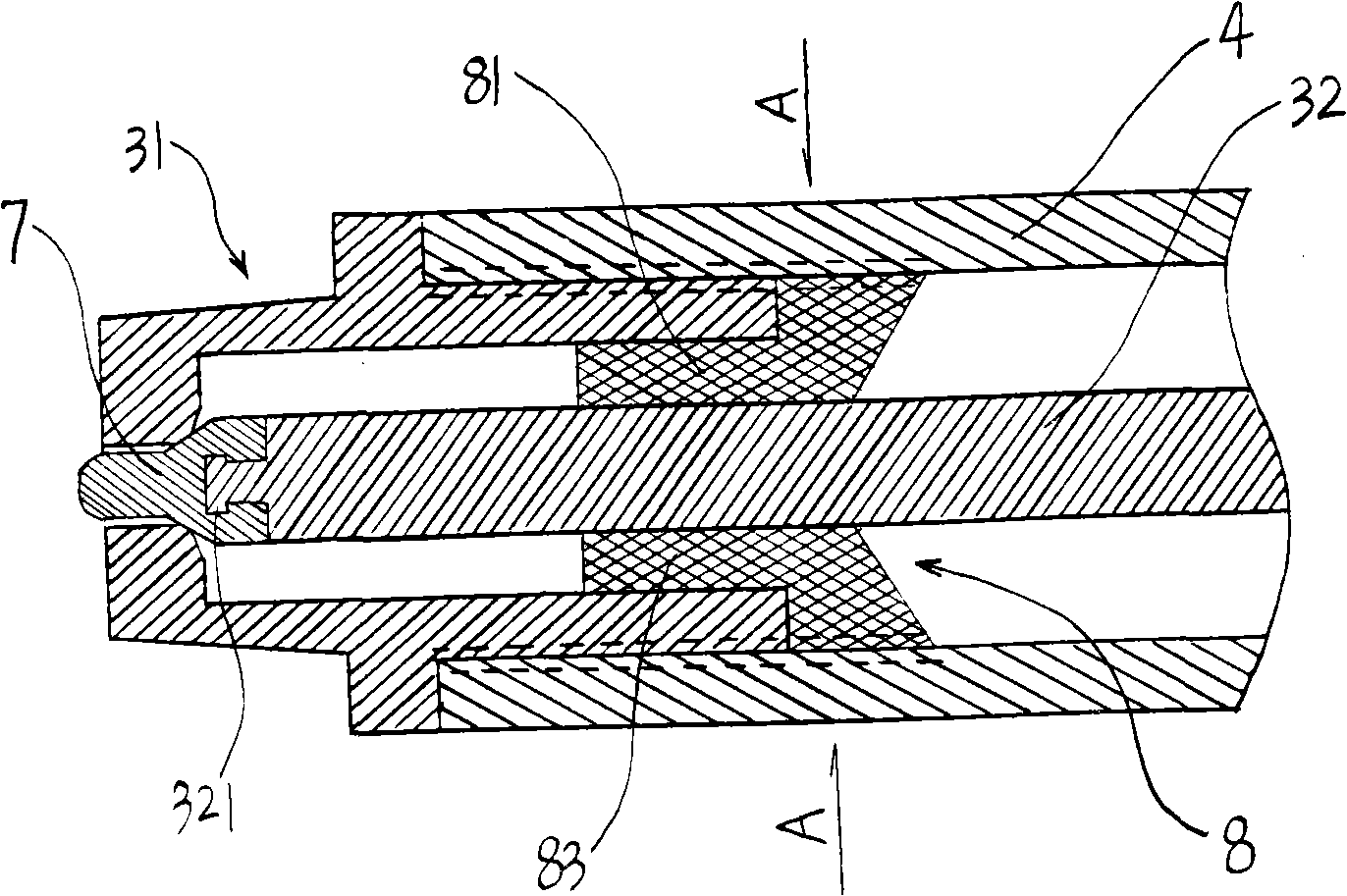

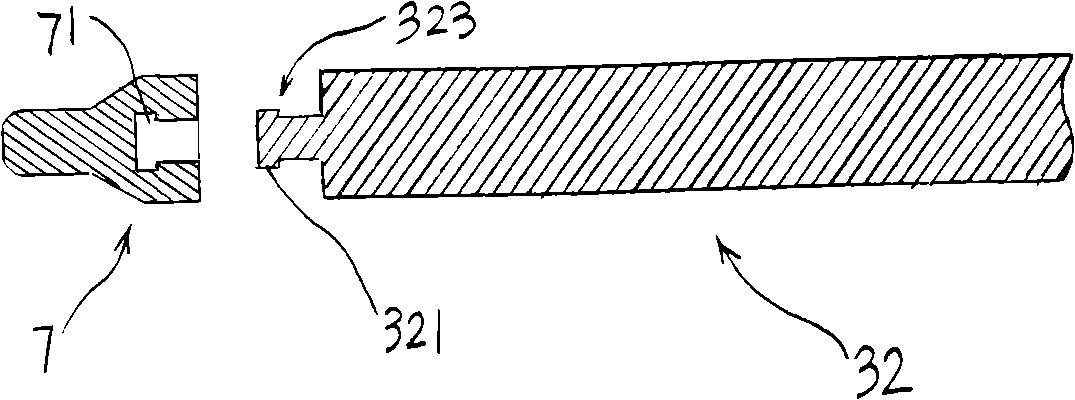

[0047]The foaming gun of the present invention includes a gun body 1, a liquid inlet valve 2, a liquid outlet valve 3, a liquid outlet channel 4 and a switch device 5, and the liquid outlet valve 3 includes a liquid outlet nozzle 31, a valve core 32 and a return spring 33, The switch device 5 can make the liquid outlet valve 3 open or close. For example, the valve core 32 has at least a part of the inner channel extending out of the foaming gun, so that the switch device 5 can directly or indirectly act on the valve core 32. A sealing member 7 is arranged on the valve core 32, and the sealing member 7 is sealed with the liquid outlet nozzle 31; a guide device 8 is arranged in the liquid outlet nozzle 31 and / or the liquid outlet channel 4 for making the The valve core 32 corresponds to the outlet 311 provided in the liquid outlet nozzle 31, which effectively prevents the channel from being blocked, and effectively prevents and avoids leakage, combustion or explosion of the foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com