Foaming tool

A tool and valve core technology, applied in the field of foaming tools, can solve the problems of leaking foam sealant, foam filler, shortening the service life of foaming tools, wear or loosening of sealing rings, etc., to improve wear resistance and low cost , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

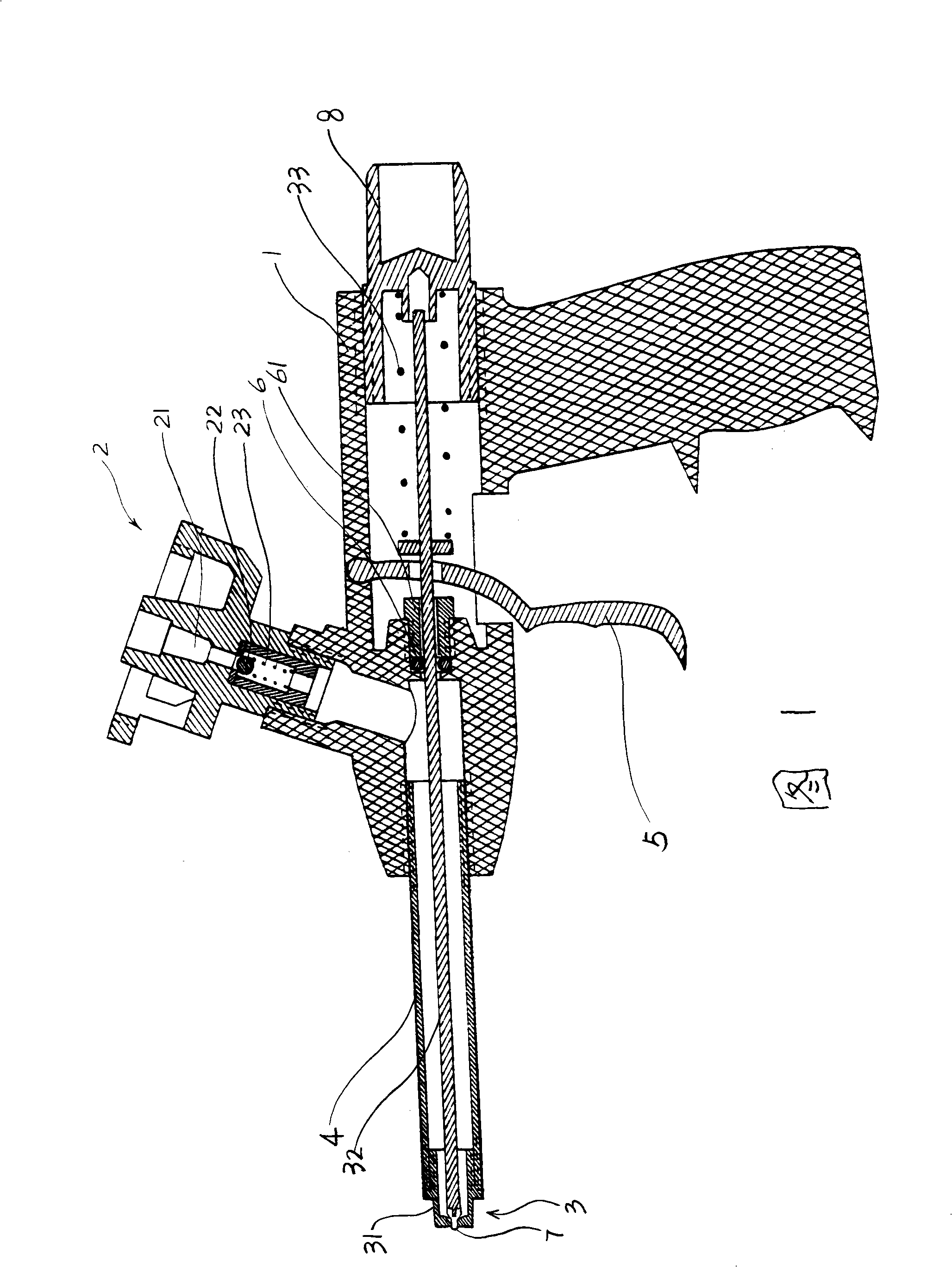

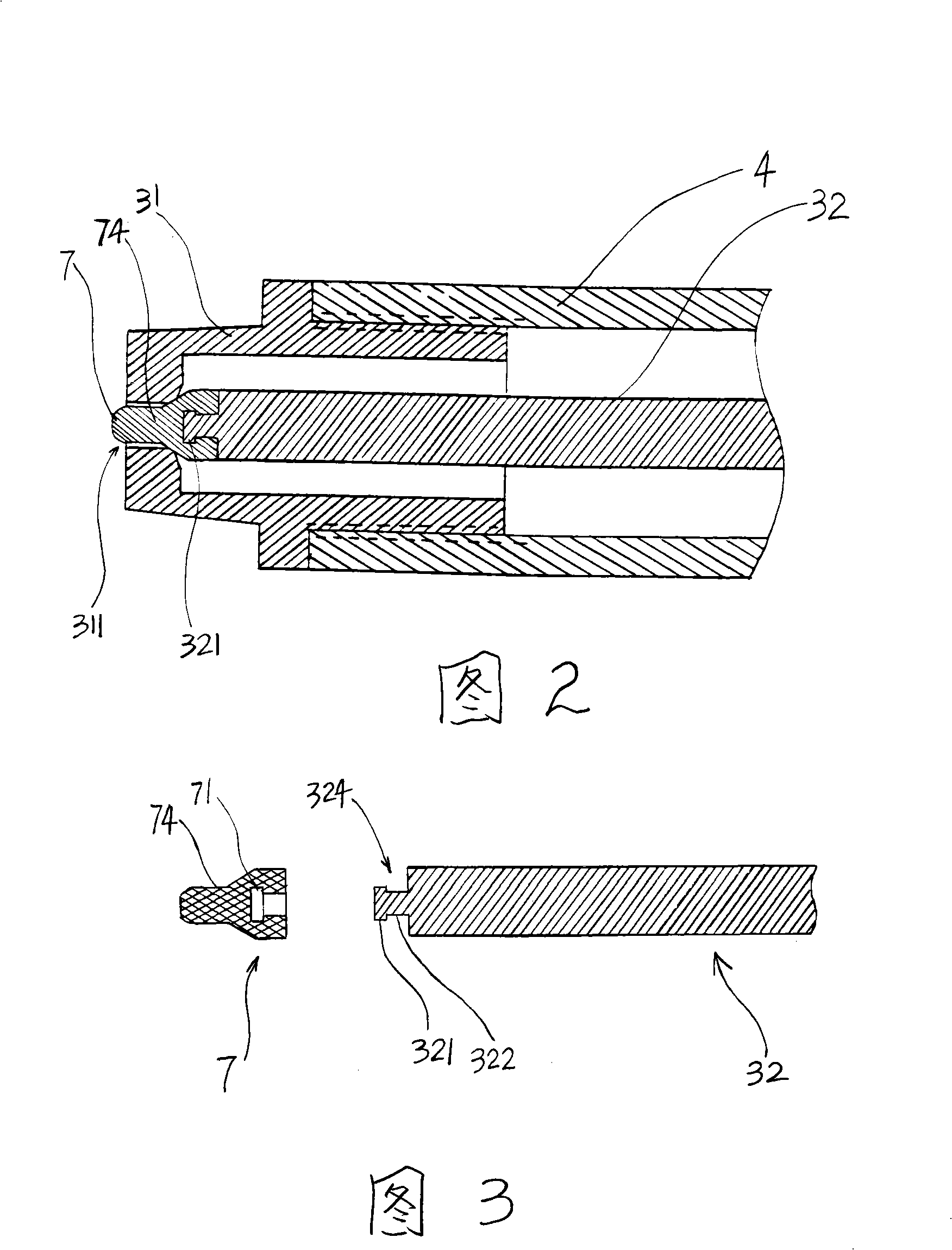

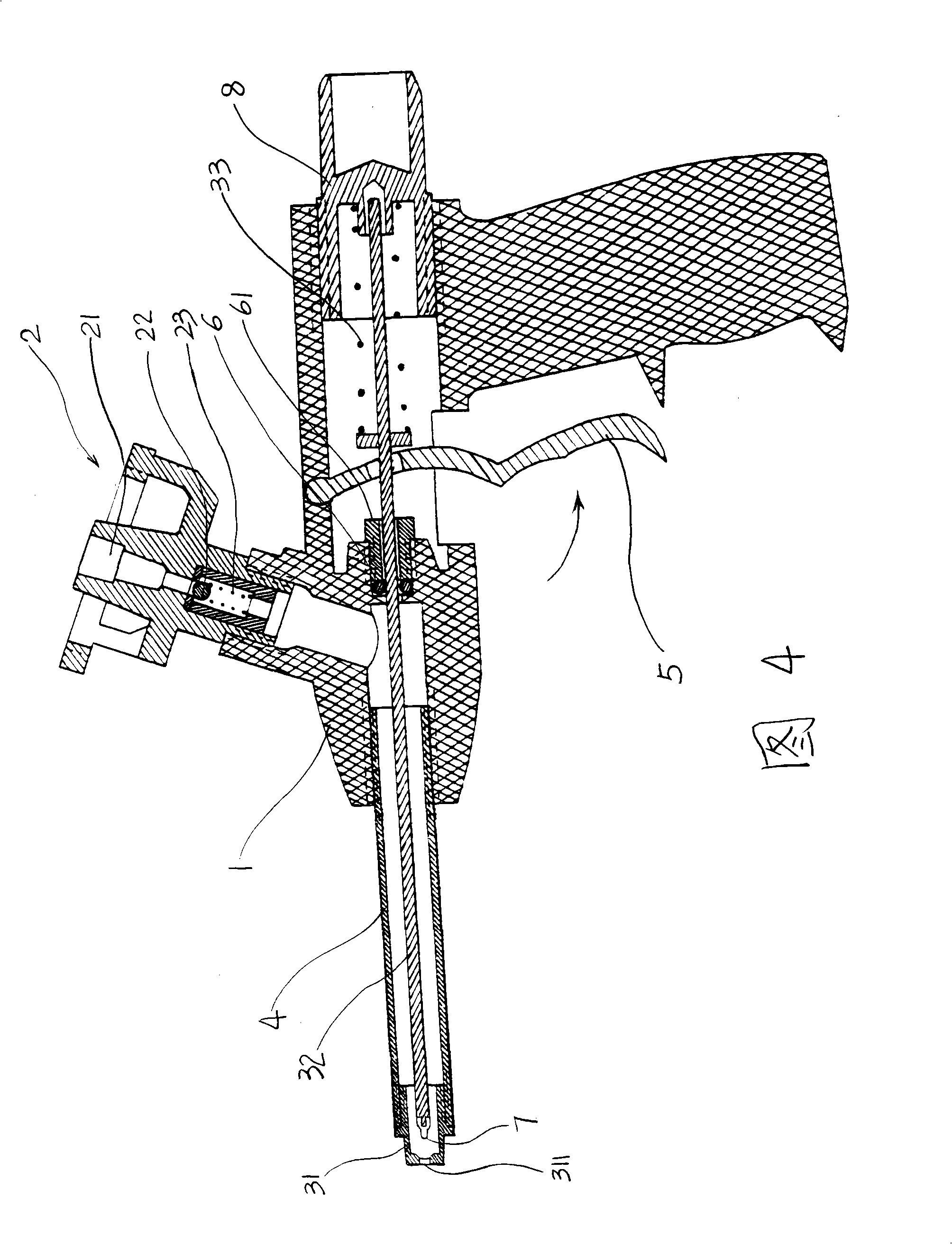

[0046]The foaming tool of the present invention comprises a gun body 1, a liquid inlet valve 2, a liquid outlet valve 3, a liquid outlet channel 4 and a switch device 5, and the liquid outlet valve 3 includes a liquid outlet nozzle 31 with an outlet 311, a valve core 32 and return spring 33, the switch device 5 can make the liquid outlet valve 3 open or close, for example, the valve core 32 has at least a part of the inner passage of the foaming tool, so that the switch device 5 can directly or indirectly act on the valve core 32 Above, the head of the spool 32 is provided with a plastic seal 7, which is connected to form an integral structure, the plastic seal 7 is sealed with the liquid outlet 31; the outlet 311 of the liquid outlet 31 is at least Part of the aperture is between 0.8 mm and 4.5 mm, or the size of the section of the inner hole of the outlet 311 of the liquid outlet 31 with the maximum transverse length is between 0.8 mm and 5 mm, which effectively prevents and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com