Folded line type concrete panel rock-fill dam and construction method thereof

A technology of concrete slab and construction method, which is applied in the direction of dams, barrages, barrages, etc., to achieve the effects of exerting benefits, shortening the construction period, and avoiding slope instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

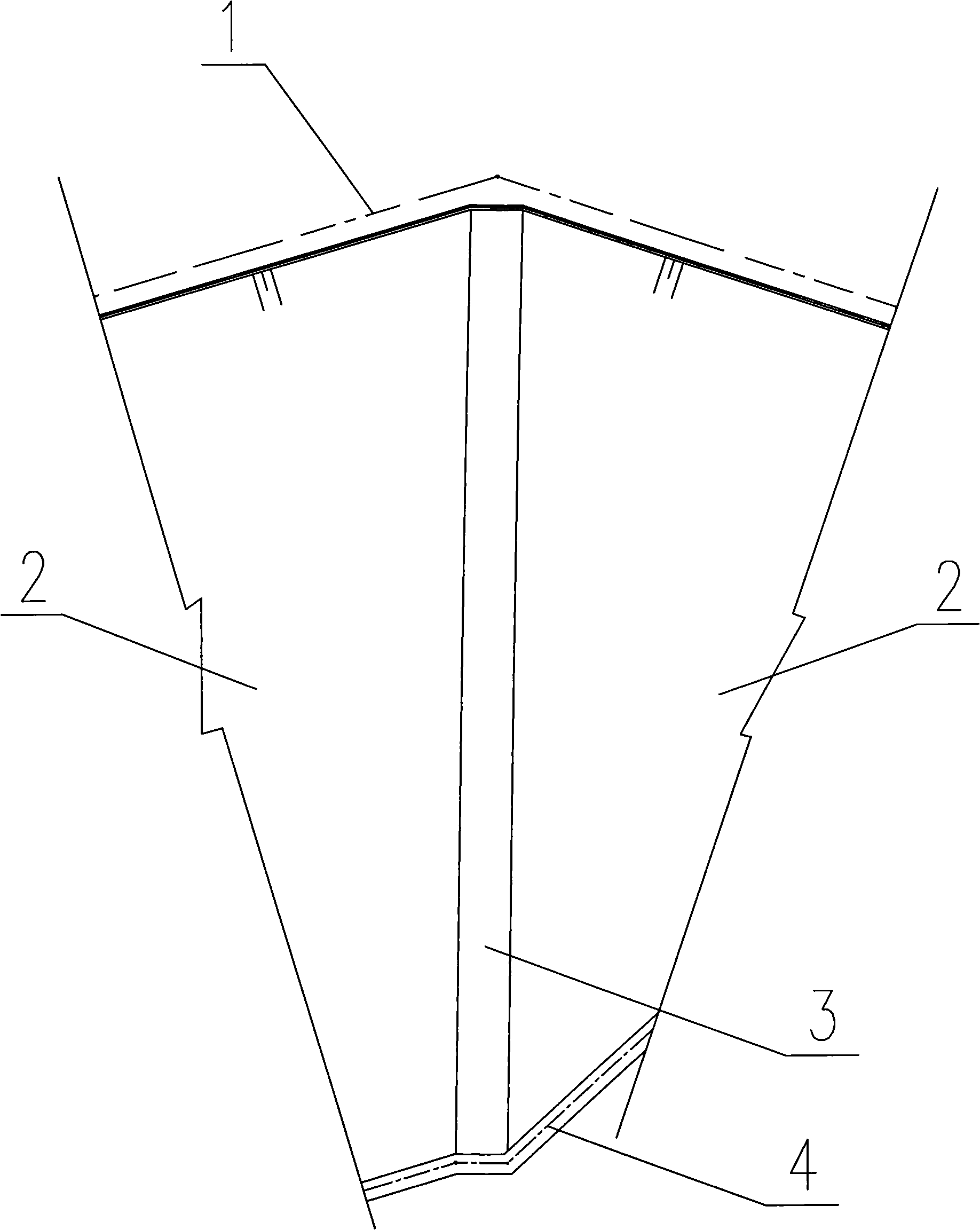

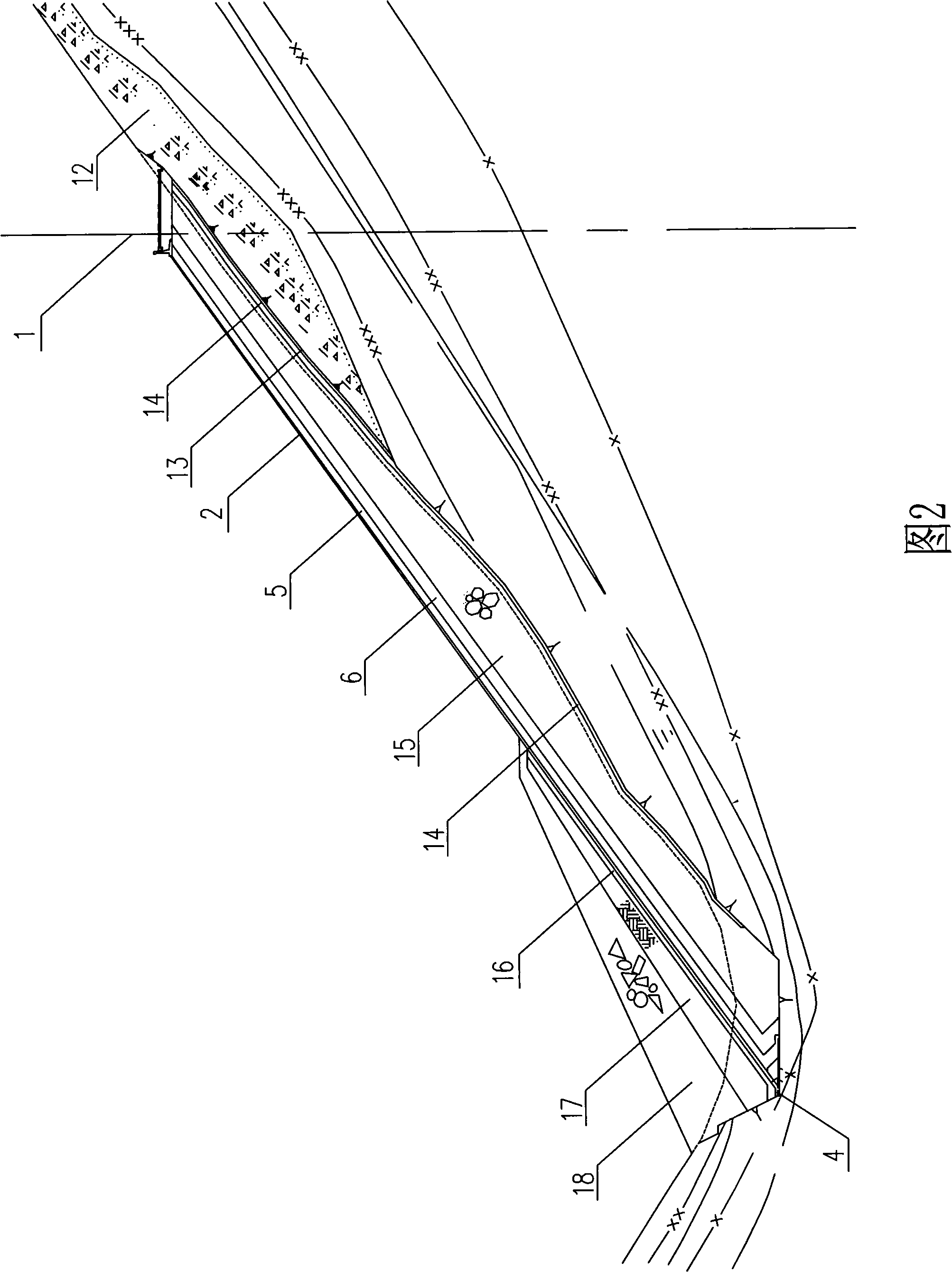

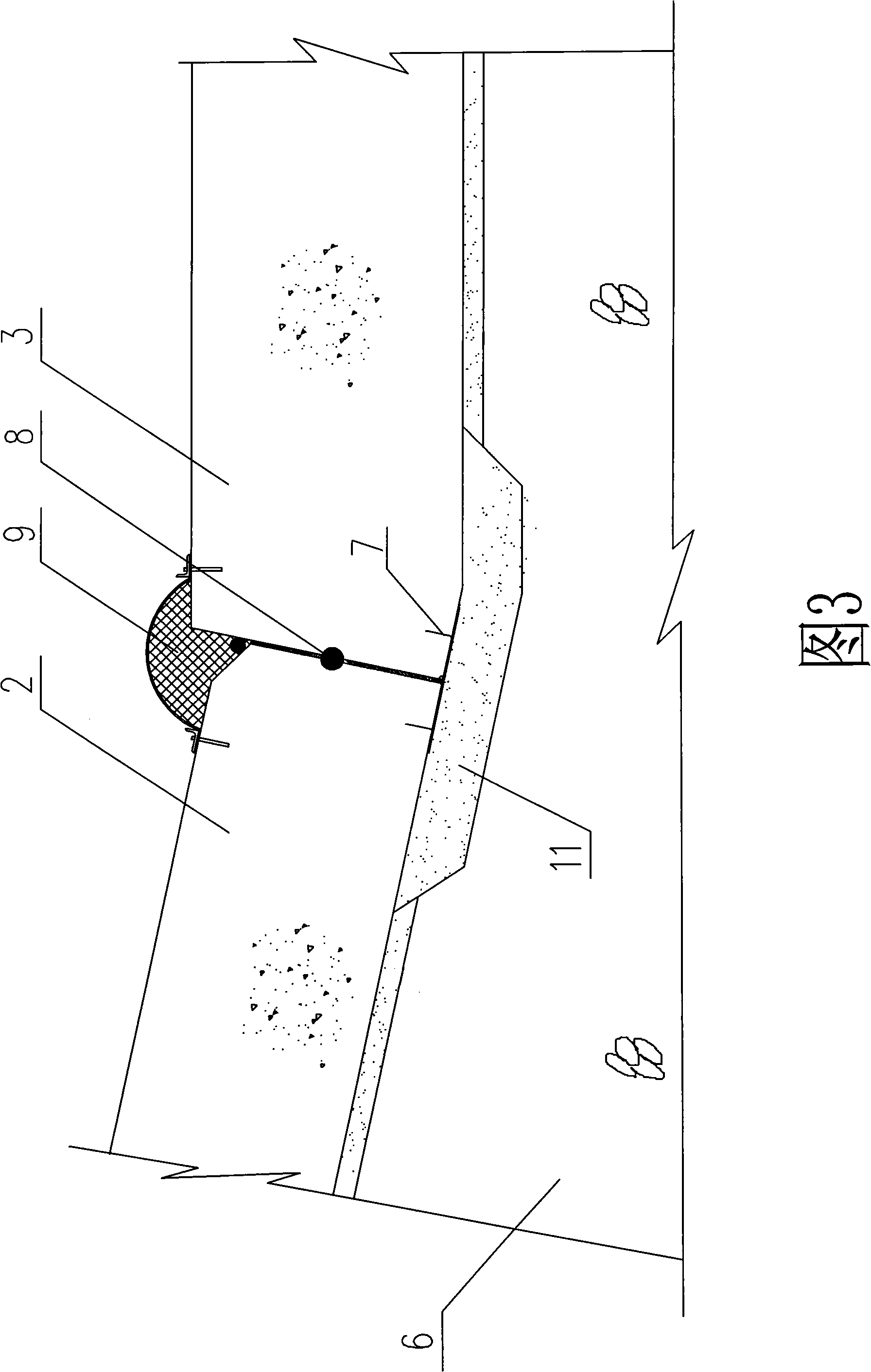

[0021] like figure 1 As shown, the broken line concrete face rockfill dam in this embodiment has a dam axis 1 and a reinforced concrete face plate 2. The characteristic of this example is that the dam axis 1 is a broken line, and the face 2 built along the dam axis also forms a broken line. The turning point of the two panels is transitionally connected by a connecting plate 3 of reinforced concrete structure, a plinth 4 of reinforced concrete structure is arranged downstream of the panels, and a cushion layer 5, a transition layer 6 and a rockfill body 15 are arranged under the panels.

[0022] The thickness of the panel 2 is: the top is 0.3m, and the bottom varies with the height according to the calculation formula d=0.3+0.0035H, wherein, H is the vertical distance from the calculated section to the top of the panel, and the unit is m.

[0023] The connecting plate 3 is set at the turning point of the panel, and the connecting plate and the two side panels are arranged acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com