Carburized and high-frequency hardened part having high strength

一种高频淬火、零件的技术,应用在机械零件领域,能够解决碳浓度差异大、高频淬火组合困难、残留碳化物量增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

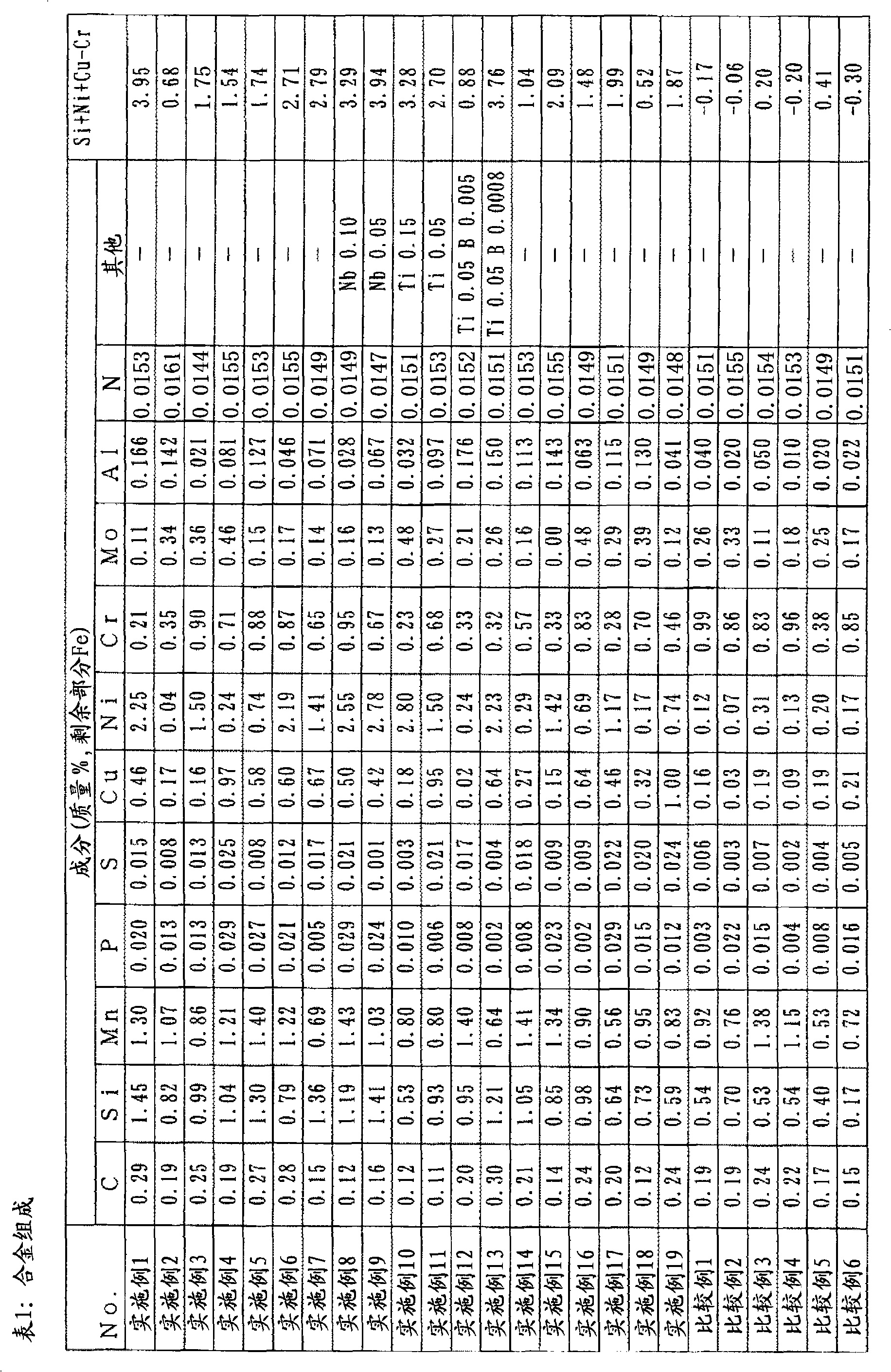

[0049] Steel for carburizing in which the alloy compositions shown in Table 1 are dissolved. Each material was machined into the following test gear shapes,

[0050] Module: 2.5 Number of gears: 30.

[0051] Pitch: 82.753mm

[0052] Gear width: 20mm

[0053] Twist angle: 25 degrees

[0054] Use acetylene gas or propane gas to maintain a temperature of 900-1050°C for vacuum carburizing. As a condition for vacuum carburizing, the degree of reduced pressure is 0.001-0.1 bar. After carburizing, use nitrogen or atmospheric gas as the refrigerant to cool slowly to below 500°C at a cooling rate of 0.1°C / s. For carburized gears, the presence or absence of carbides and the surface carbon concentration were measured.

[0055] The gear surface after slow cooling was subjected to induction hardening under the following conditions to harden the gear surface.

[0056] Heating: 760~900℃ within 10 seconds

[0057] Keep: 760~900℃ within 1 minute

[0058] Quenching: 200~2000℃ / sec water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com