Technique for decarbonizing fly ash with high ignition loss

A fly ash, loss on ignition technology, applied in solid separation, flotation, etc., can solve the problems of large fly ash loss on ignition, high carbon content in fly ash, no use value, etc., and achieve large processing capacity , high output and high flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

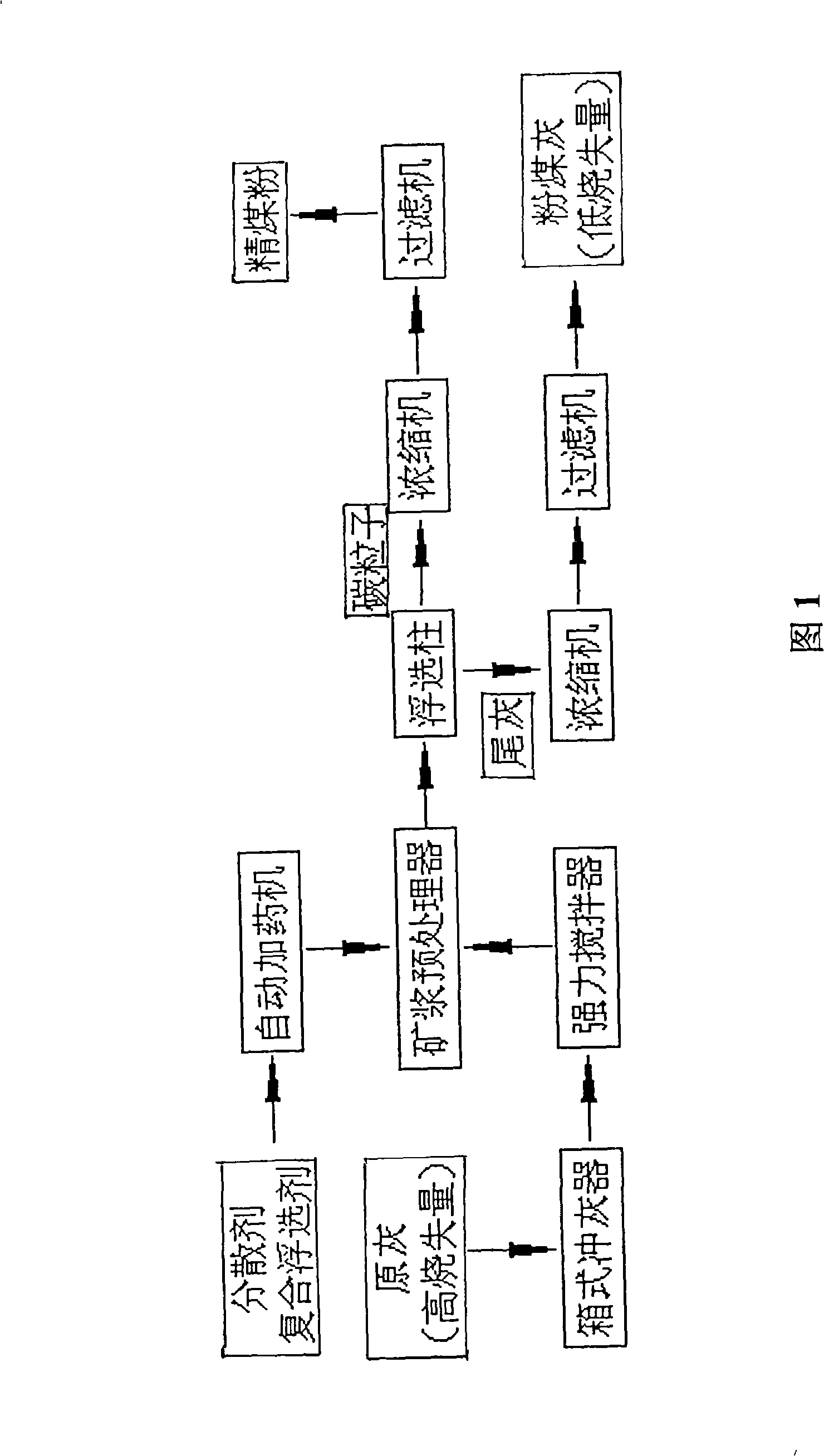

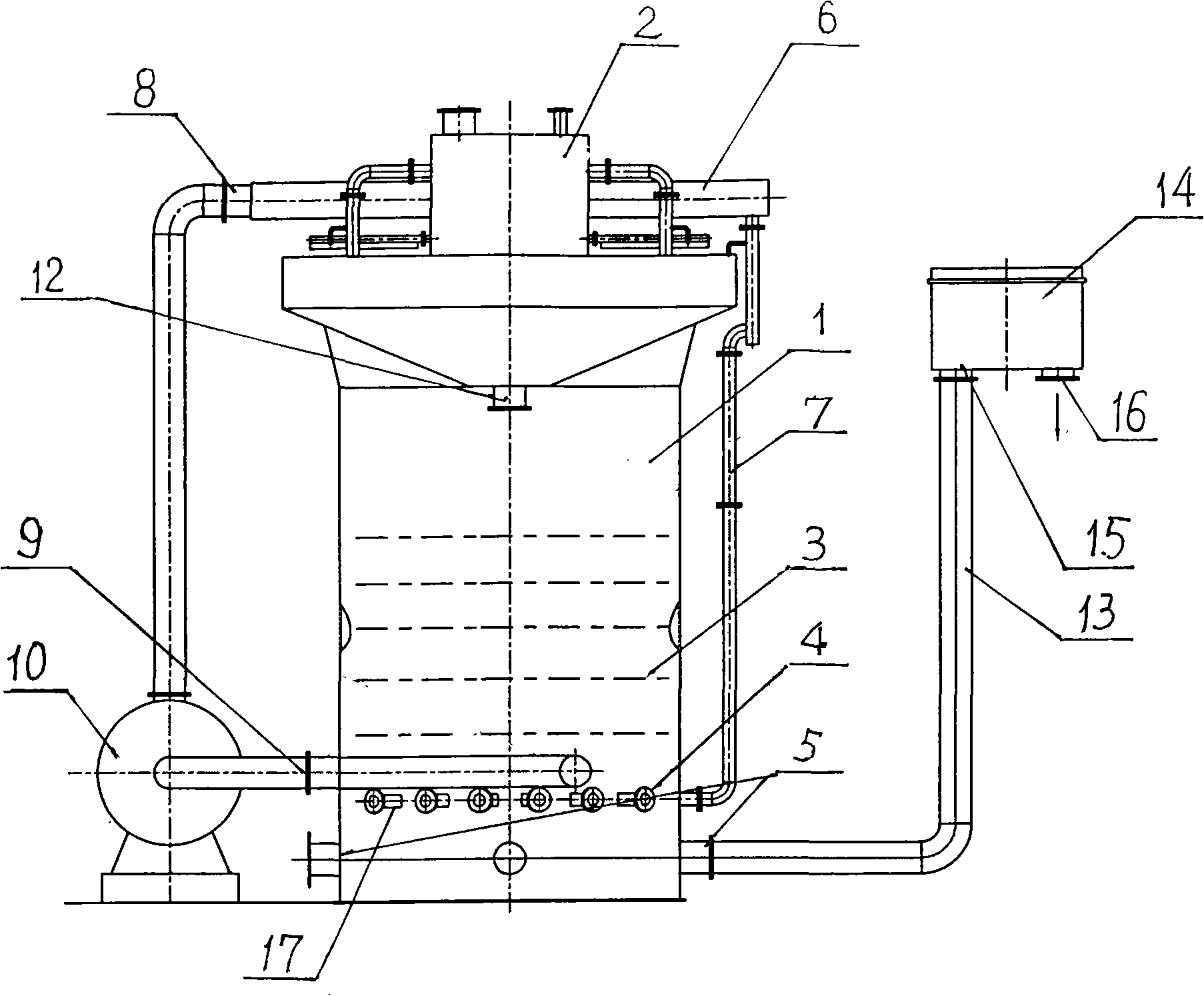

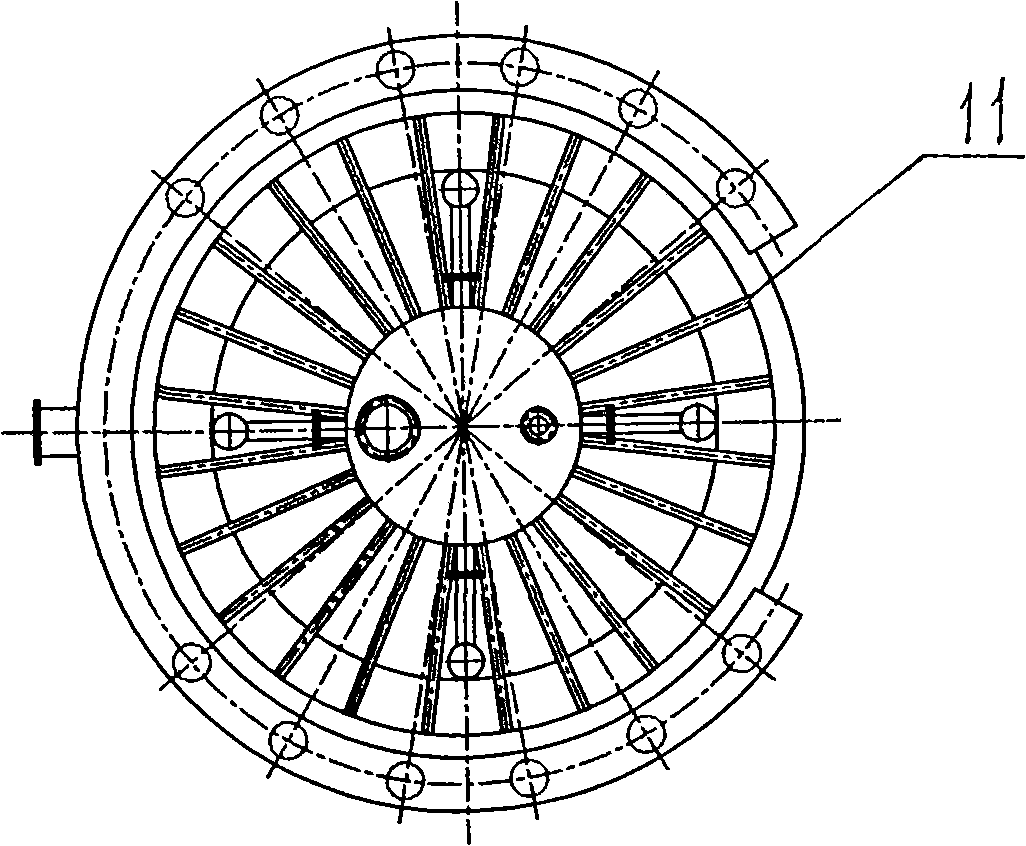

[0075] Referring to Fig. 1, the process of the present invention is as follows: the original ash of fly ash is transported to the ash storage tank of the treatment plant by a bulk tanker, the output of the ash storage tank is measured by an electronic weighing scale, and then enters a box-type ash flusher, and enters through a powerful mixer. In the pulp preprocessor, the electronic measuring scale is the existing technology, which is available in the market and has various varieties. The box-type ash flusher is the existing technology, such as the XBL1 600-6M box-type ash flusher manufactured by Zhejiang Changxing Zhongke Machinery Factory , strong mixer is also prior art, as the JP-2500 type fly ash special mixing tank produced by Wuxi Shenquan Machinery Co., Ltd. After the raw ash enters the pulp preprocessor, the automatic dosing machine will add the dispersant and compound flotation agent to the pulp preprocessor for mixing and stirring. After separation, the carbon parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com