Raceway-parallel storing type parking equipment using shears-fork type buck stacker

A technology of parking equipment and stacker, which is applied in the field of side-by-side storage parking equipment with raceways, can solve the problems of inability to reflect the advantages, not seen, and high construction investment, and achieve the simplification of the installation inspection process and standard requirements, and the convenience of maintenance operations , the effect of simple structure composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

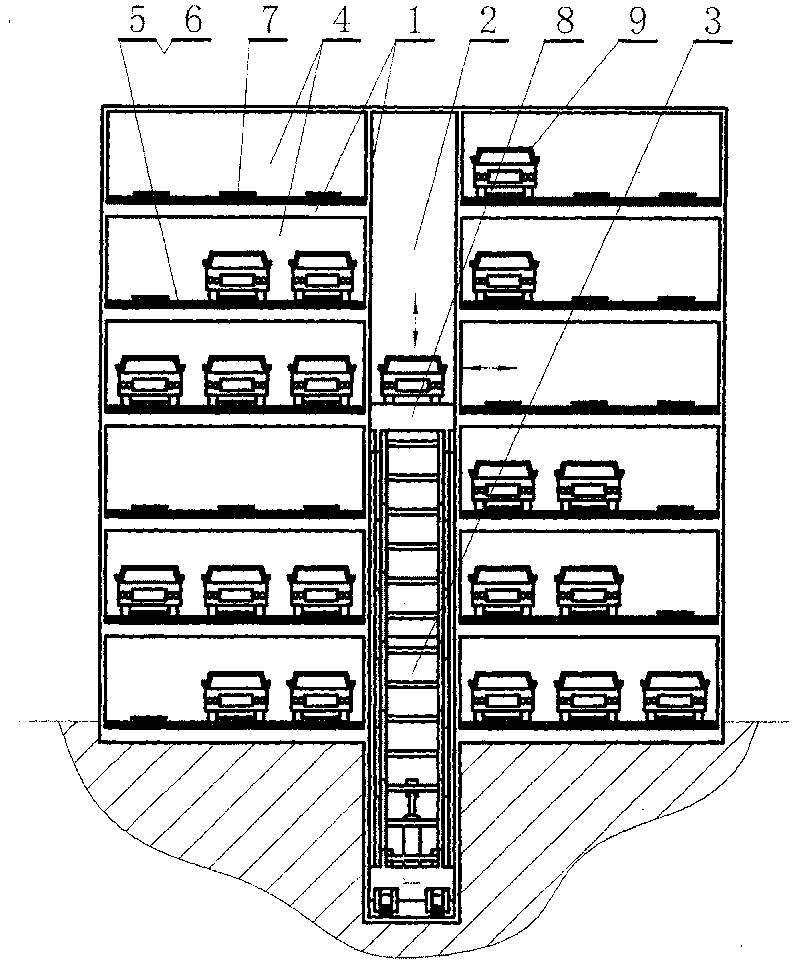

[0024] Such as Figure 1 to Figure 5As shown, this embodiment includes: warehouse-style warehouse rack 1, roadway 2, vehicle entrance and exit 3, car storage area 4, front wheel supporting and placing raceway 5, rear wheel supporting and placing raceway 6, vehicle separation and positioning lateral movement pick-up device 7 , Scissor-type handling stacker 8; the warehouse rack 1 is built on the ground or built underground or partly built underground, the roadway 2 is located in the middle of the warehouse rack 1, and the bottom or top layer of the roadway 2 or a certain layer in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com