Network frame house cap integral lifting construction method

A construction method and roofing technology, applied in building maintenance, construction, building construction, etc., can solve problems such as large amount of engineering, long construction period, and difficult reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

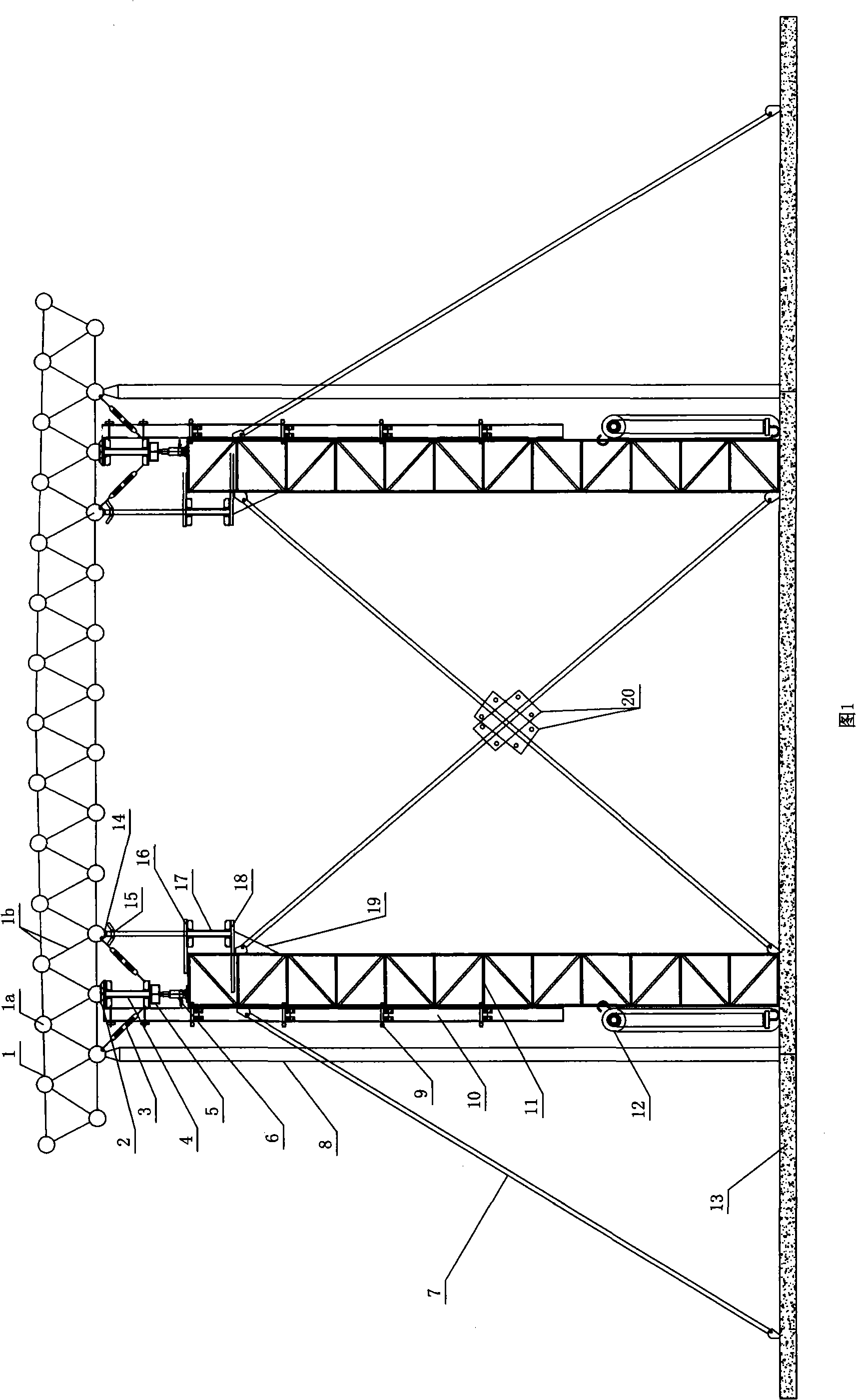

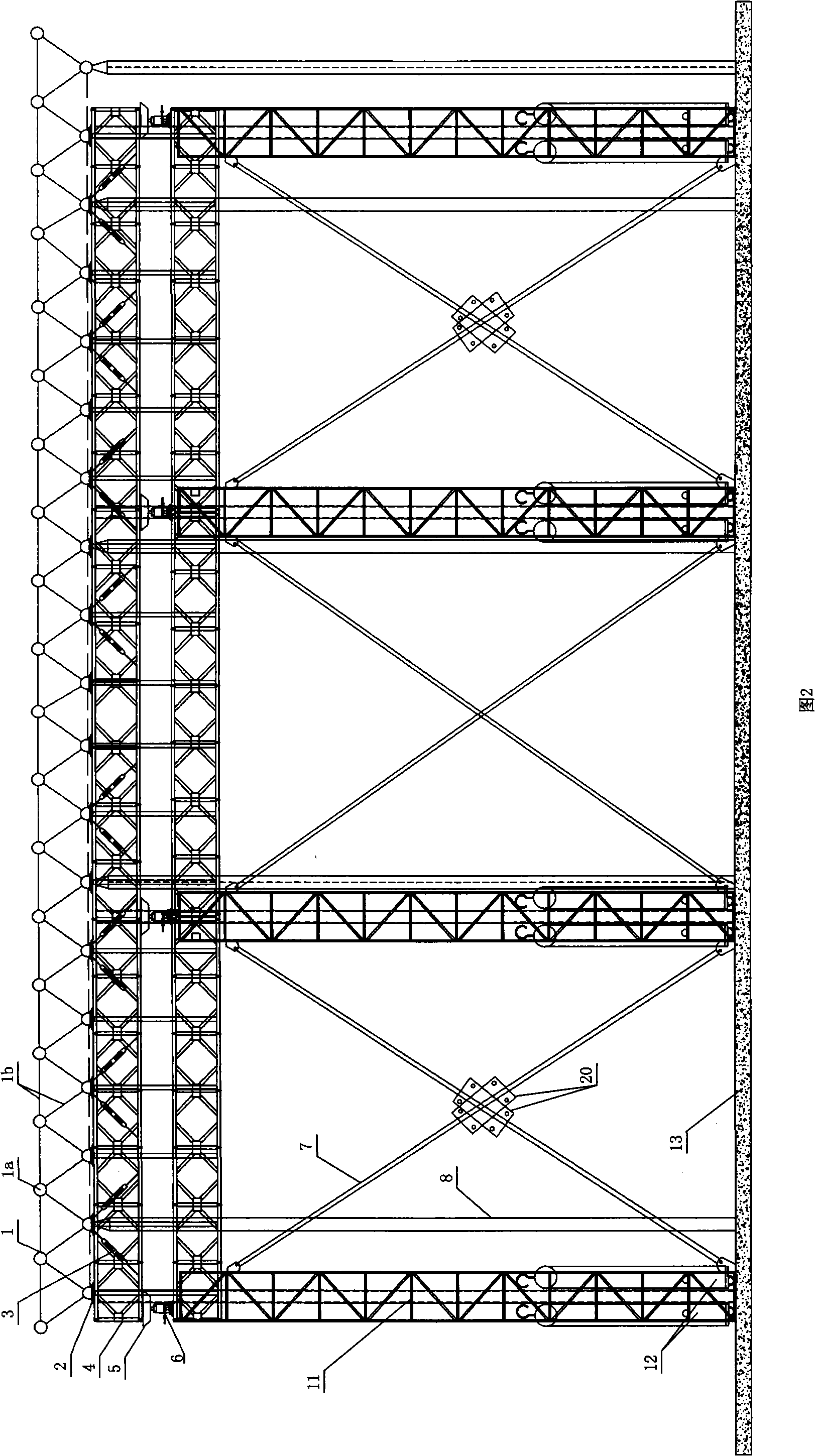

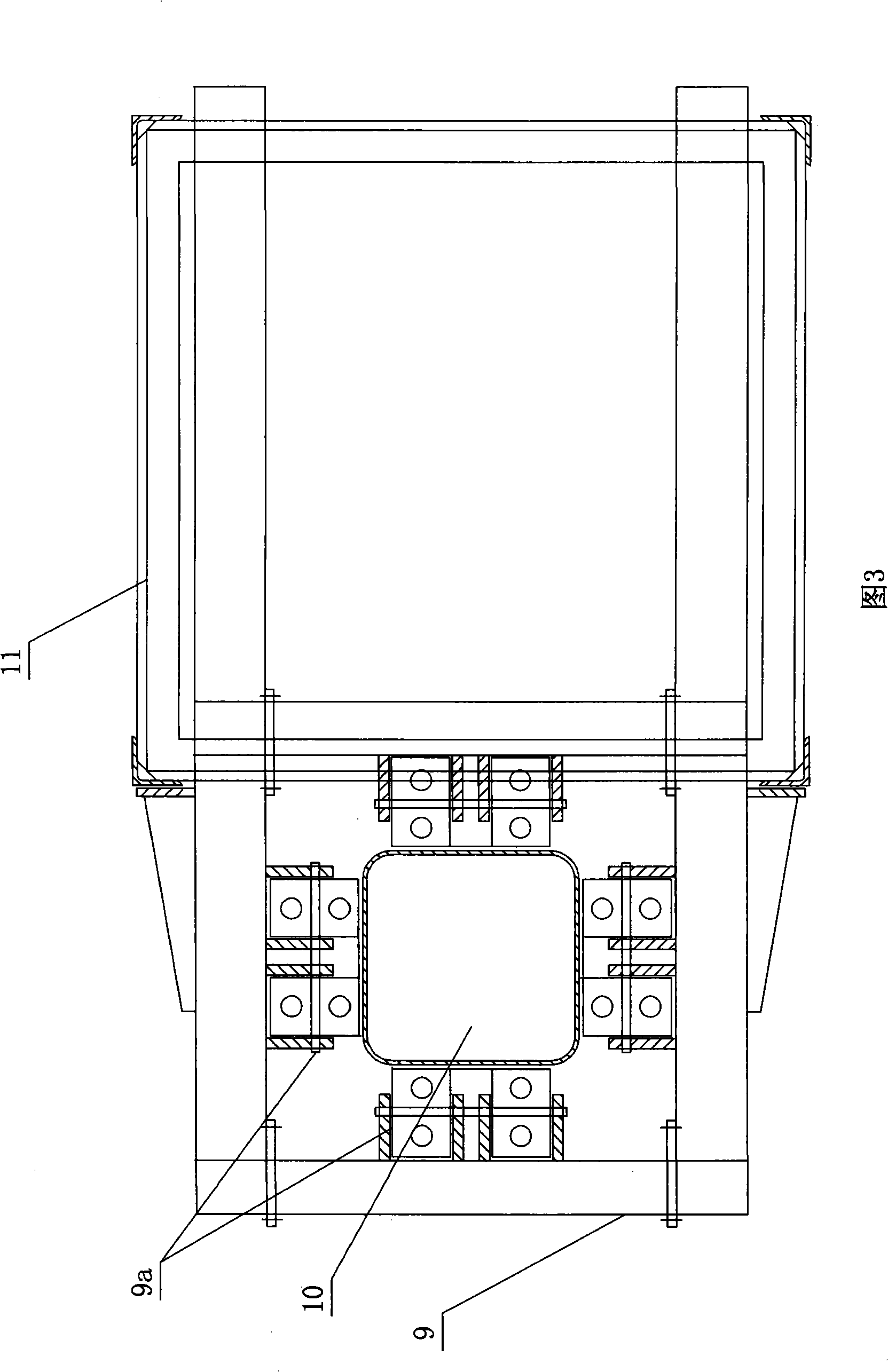

[0033] The overall lifting construction method of the grid roof is aimed at the grid roof 1, which is composed of node balls 1a and tie rods 1b. The cover 1 is supported and fixed by the column 8, and the construction method includes the following steps:

[0034] (1) According to the shape and load-bearing distribution of the grid roof 1, the distribution positions of the load-bearing columns 11 are pre-designed, and the pressure-resistant road slab ground beams 13 are poured on the ground corresponding to the distribution positions of the load-bearing columns 11, and the load-bearing columns 11 are erected at the corresponding distribution positions. Diagonal tie rods 7 are set between the load-bearing column 11 and the pressure-resistant road slab floor beam 13. Diagonal stay rods 7 are respectively arranged on the four sides of the load-bearing column 11. The intersecting positions of the diagonal stay rods 7 of adjacent load-bearing columns 11 are coordinated by setting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com