Processing system and method for printing and dyeing wastewater

A technology for printing and dyeing wastewater and treatment methods, which is applied in textile industry wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., and can solve problems such as high-power heaters that cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

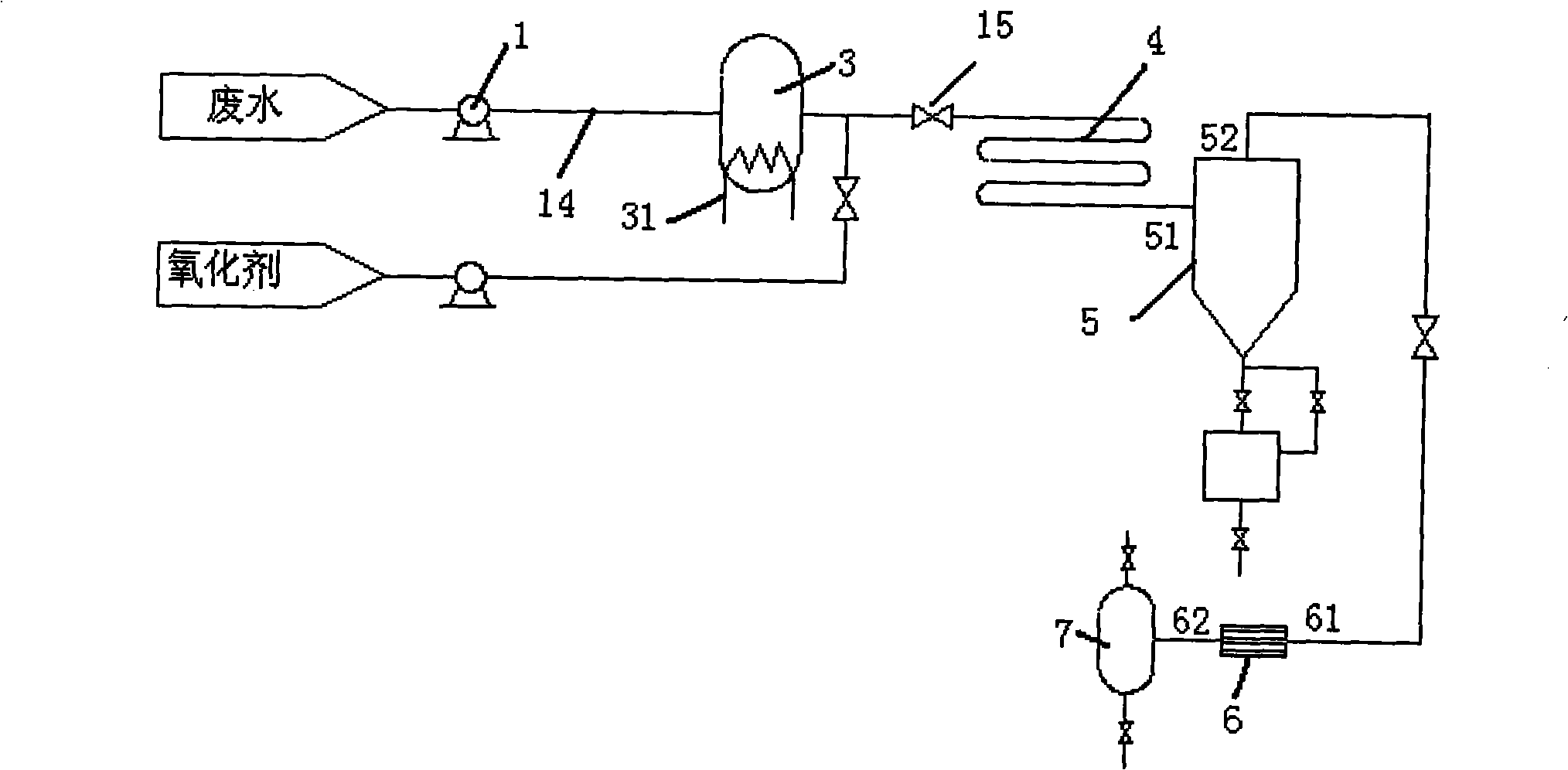

[0034] Such as figure 1 As shown, a treatment system for printing and dyeing wastewater includes a high-pressure plunger pump 1, a delivery pipeline 14, a reactor 4 and a first gas-liquid separator 7, and a high-pressure plunger pump 1, a reactor 4 and a first gas-liquid separator 7 are sequentially connected through the delivery pipeline 14, the high-pressure storage tank is connected between the high-pressure plunger pump 1 and the reactor 4 through the delivery pipeline, and a valve 15 is arranged on the pipeline 14 between the high-pressure storage tank 3 and the reactor 4, and the high-pressure storage tank The tank 3 is also provided with a heater 31 . The reactor 4 adopts a tubular reactor, because the reactor has a certain length, and the mixed liquid flows in it, resulting in a certain residence time.

[0035] A high-pressure hydrocyclone 5 and a first heat exchanger 6 are connected between the reactor 4 and the first gas-liquid separator 7, the input port 51 of the ...

Embodiment 2

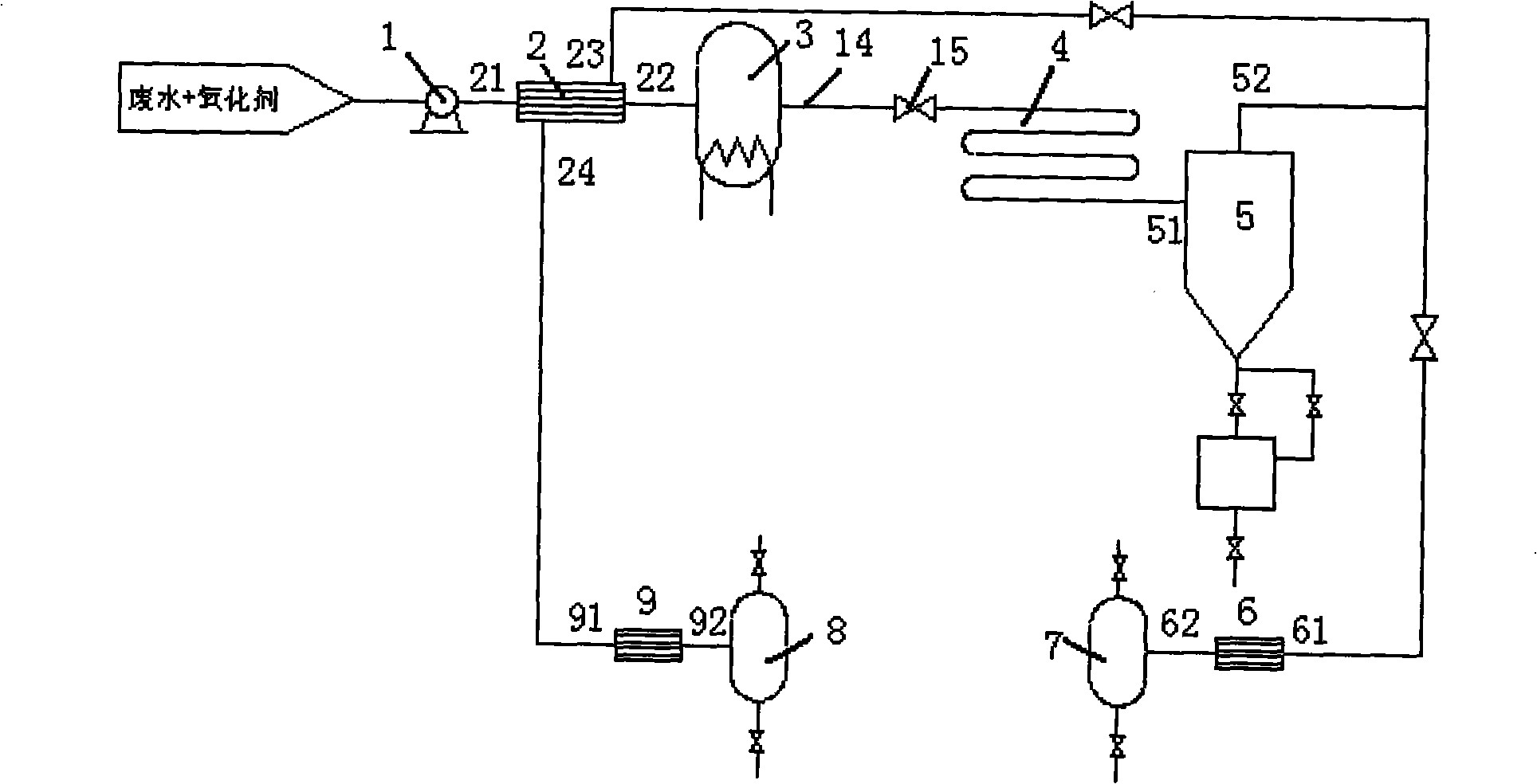

[0037] Such as figure 2 As shown, this embodiment is basically the same as the previous example, the difference is:

[0038]The second heat exchanger 2 is arranged between the high-pressure plunger pump 1 and the high-pressure storage tank 3, the high-pressure plunger pump 1 is connected to the first input port 21 of the second heat exchanger, and the first output port 22 of the second heat exchanger Connect the input port of high-pressure storage tank 3 through delivery pipeline 14; The input port 91 of the third heat exchanger 9 and the output port 92 of the third heat exchanger are connected to the input port of the second gas-liquid separator 8 .

[0039] The setting of the second heat exchanger 2 can enable heat exchange between the output liquid treated by the reactor 4 and the waste water mixed liquid output by the high-pressure plunger pump, preheat the waste water mixed liquid, and save the time required for heating the waste water mixed liquid to a supercritical st...

Embodiment 3

[0058] A treatment method for printing and dyeing wastewater, comprising the following steps:

[0059] (1) According to the ratio of adding NaClO511.8g per liter of printing and dyeing wastewater, the wastewater and NaClO are respectively injected into the high-pressure storage tank through a high-pressure plunger pump, and then fully mixed;

[0060] (2) Make the above-mentioned mixed liquid be filled in the high-pressure storage tank, close the high-pressure plunger pump, close the valve between the high-pressure storage tank and the reactor; statically heat the mixed liquid in the high-pressure storage tank with a heater;

[0061] (3) When the pressure in the high-pressure storage tank reaches 25Mpa and the temperature reaches 600°C, open the valve between the high-pressure storage tank and the reactor, and start the high-pressure plunger pump at the same time;

[0062] (4) The high-pressure plunger pump pressurizes the above-mentioned mixed solution to 25Mpa, injects it int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com