Dynamoelectric proportion valve automatic subsection antifreeze constant temp gas water heater

A technology for electric proportional valves and gas water heaters, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as inability to maintain constant temperature, failure to reduce firepower, and fluctuations in outlet water temperature, and achieve simple and effective control. Increase the effect of easy to use and advanced structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

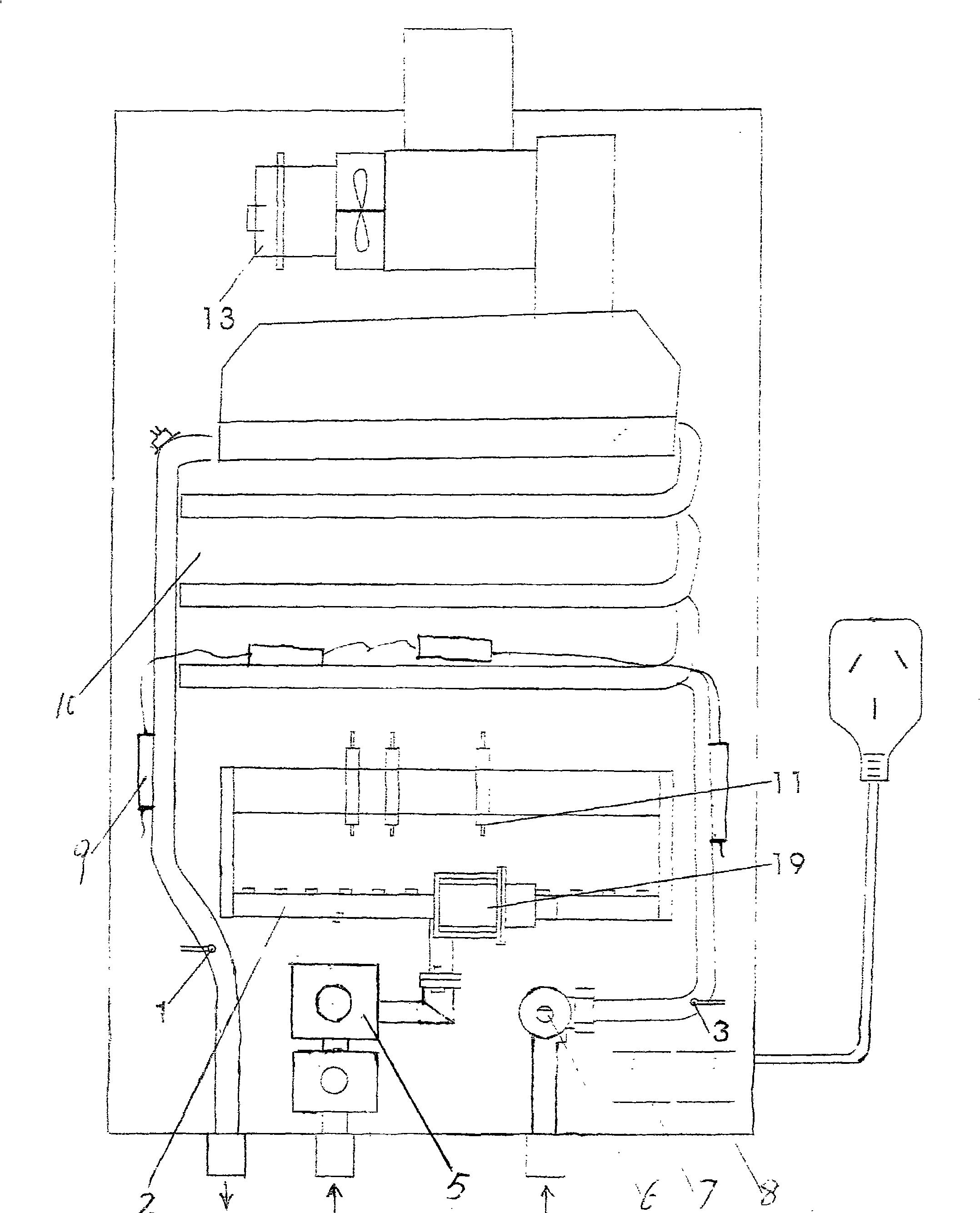

Image

Examples

Embodiment 1

[0028] The water outlet temperature sensor 1, the water inlet temperature sensor 3, the Hall water flowmeter 6, the photoelectric head 12, the stepping motor 16, the setting button 23 are connected with the single chip microcomputer 25. The single-chip microcomputer 25 samples the set temperature values of the Hall water flow meter 6 and the water inlet temperature sensor 3 from time to time respectively. When the flow rate of the water flow meter 6 reaches a certain value, the single-chip microcomputer 25 commands: atmospheric ignition, the opening of the gas valve core 4 is 35%, the stepping motor 16 rotates, and the gear 17, the gear 18, the valve plate 27, and the gas valve core 4 are opened. When the photoelectric head 12 reads the data of the code disc 15 as 35% of the stroke, the stepper motor 16 rotates and stops, and the opening of the valve plate 27 gas valve core 4 is set at 35%; the electromagnetic valve 5 is opened, and the gas passes through the valve seat 28, t...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is: there is no code disc 15 and photoelectric head 12 in embodiment 2. In the initial state, the initial switch 13 resets the counter of the memory stepping motor 16 rotation steps to zero. Valve plate 27 and valve seat 28 block the gas path. When the single-chip microcomputer 25 instruction gas valve core 4 was opened 35%, the single-chip microcomputer 25 directly provided the steps that the stepper motor 16 rotated and rotated, and the valve plate 27 gas valve core 4 produced 35% vent holes. The size of the range of steps that the stepper motor 16 rotates is proportional to the size of the range of the gas flux produced by the valve plate 27 gas valve core 4 and the valve seat 28 .

Embodiment 3

[0036] The difference between embodiment 3 and embodiment 1 is: there is no code disc 15 photoelectric head 12 and start switch 13 in embodiment 3. Use mechanical limiter, valve plate 27 and valve seat 28 block the gas path in the initial state, the gas hole on the gas valve core 4 is blocked by valve seat 28 or leaves a minimum hole. The counter of the stepping motor 16 rotation steps is automatically reset, and the valve position output of the single-chip microcomputer 25 is marked as the gas valve core 4 at the initial opening position. The opening degree of the gas valve core 4 controlled by the operation output of the single-chip microcomputer 25 is exactly the number of steps of the stepping motor 16 corresponding to the ratio. The size of the range of steps that the stepper motor 16 rotates is proportional to the size of the range of the gas flux produced by the valve plate 27 gas valve core 4 and the valve seat 28 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com