Inner core acceleration type cyclone separator

A cyclone separator, accelerated technology, applied in suction filters, cyclone devices, and devices whose axial directions of cyclone can be reversed, etc., can solve the problem of poor filtering effect of fine dust particles, low cyclone angular velocity, and more energy consumption. and other problems, to achieve the effect of reducing the volume, increasing the air volume, and increasing the ash storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

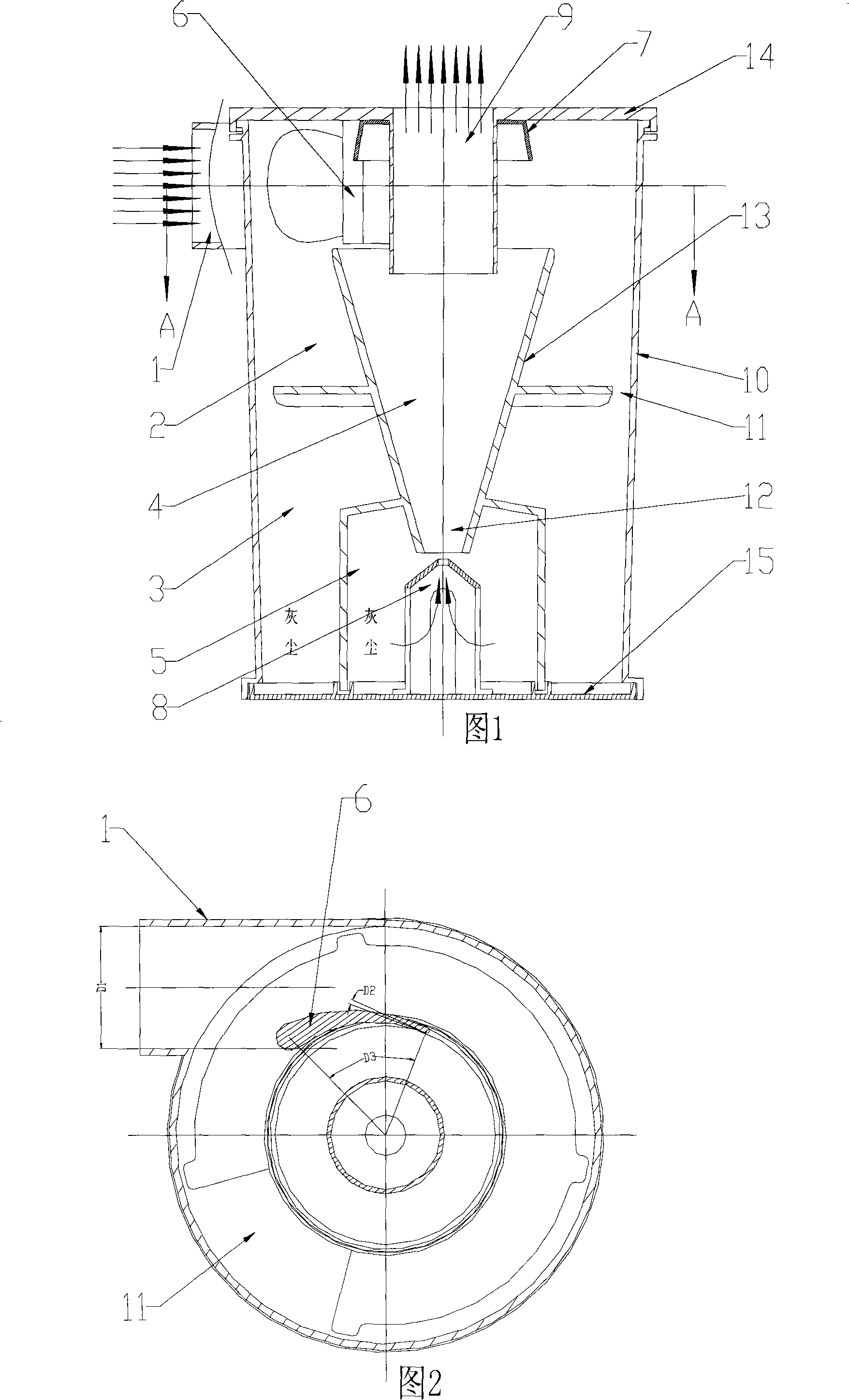

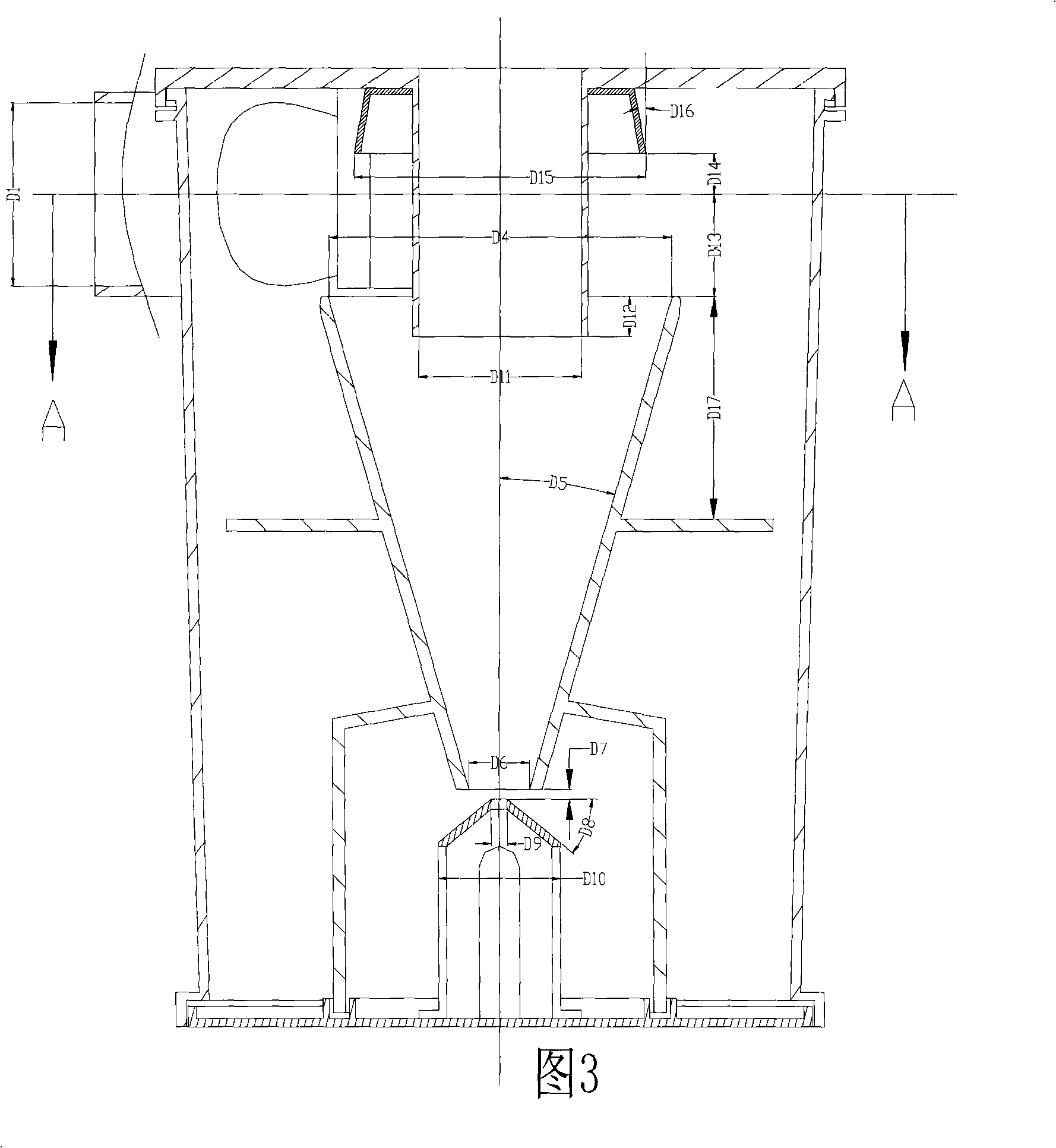

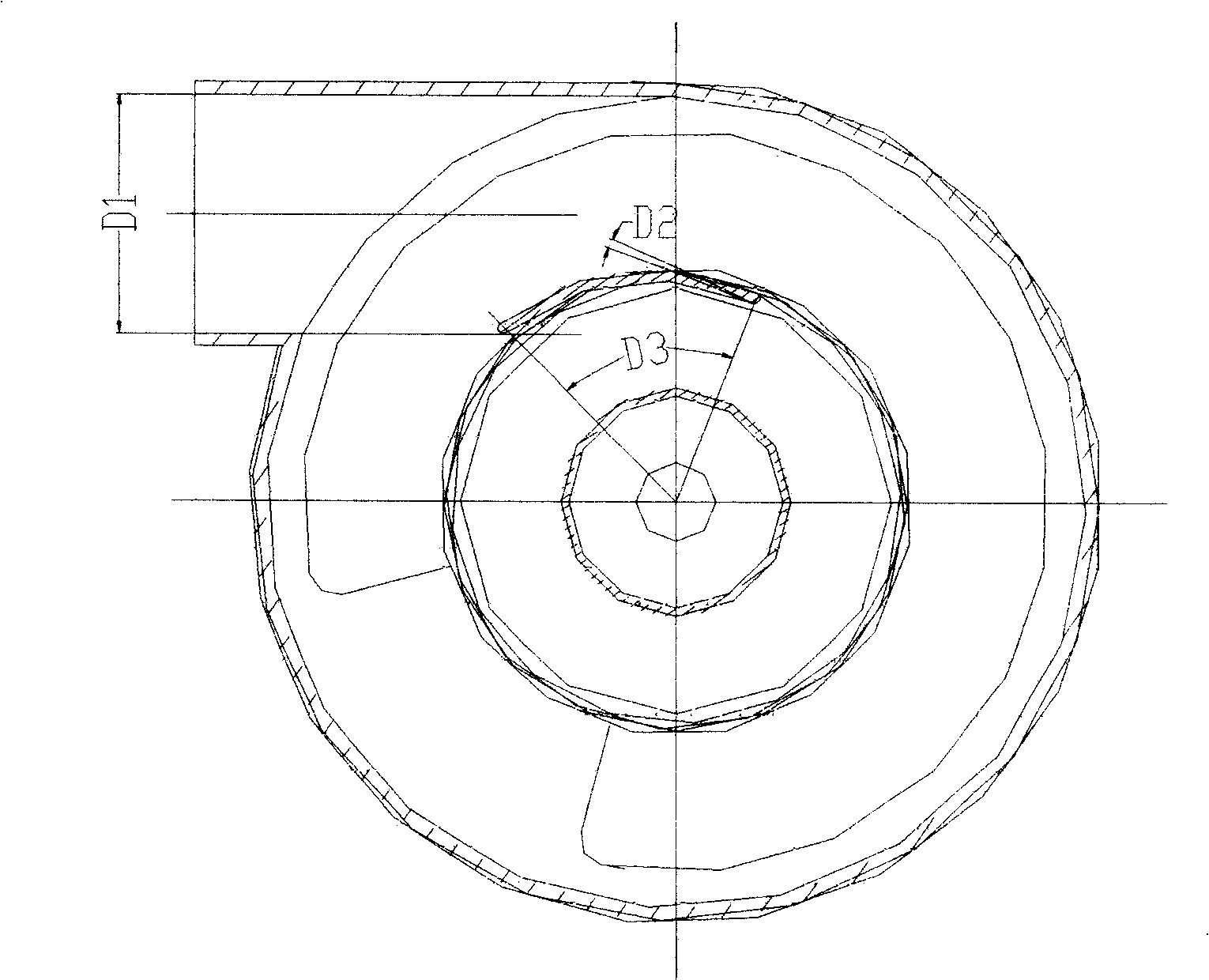

[0023] As shown in Figure 1 and Figure 2, a cyclone separator dust removal device for a vacuum cleaner, the specific components include a dust cup 10, a cyclone core assembly 13, a dust cup upper cover 14, a dust cup lower cover 15, an annular dust retaining plate 7, Reflective screen8. The dust-laden airflow enters the dust cup 10 along the tangent line of the dust cup wall from the air inlet 1 of the dust cup, and the dust-laden airflow rotates in the upper part of the dust cup 10, and part of the dust gathers to the dust cup wall during the rotation process and passes through the outer cyclone chamber to drop dust The gap 11 falls into the bottom of the dust cup. The other part of the dust enters the cyclone core 13 smoothly from the upper edge of the cyclone core 13 with the air flow, and the dust-laden air flow accelerates in a cone with a large upper end and a small lower end, and the fine dust particles enter the dust cup from the exit of the small end of the cone. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com