Oil smoke filtering assembly reticular lamina

A technology of oil fume filtering and screen plate, applied in the field of range hoods, can solve the problems of affecting the purification effect of inhaled oil fume, difficult to clean, etc., so as to increase the probability of being thrown to the boundary of the flow channel, improve the effect, and increase the probability of adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be further described by taking the circular air inlet as an example in conjunction with the drawings and embodiments.

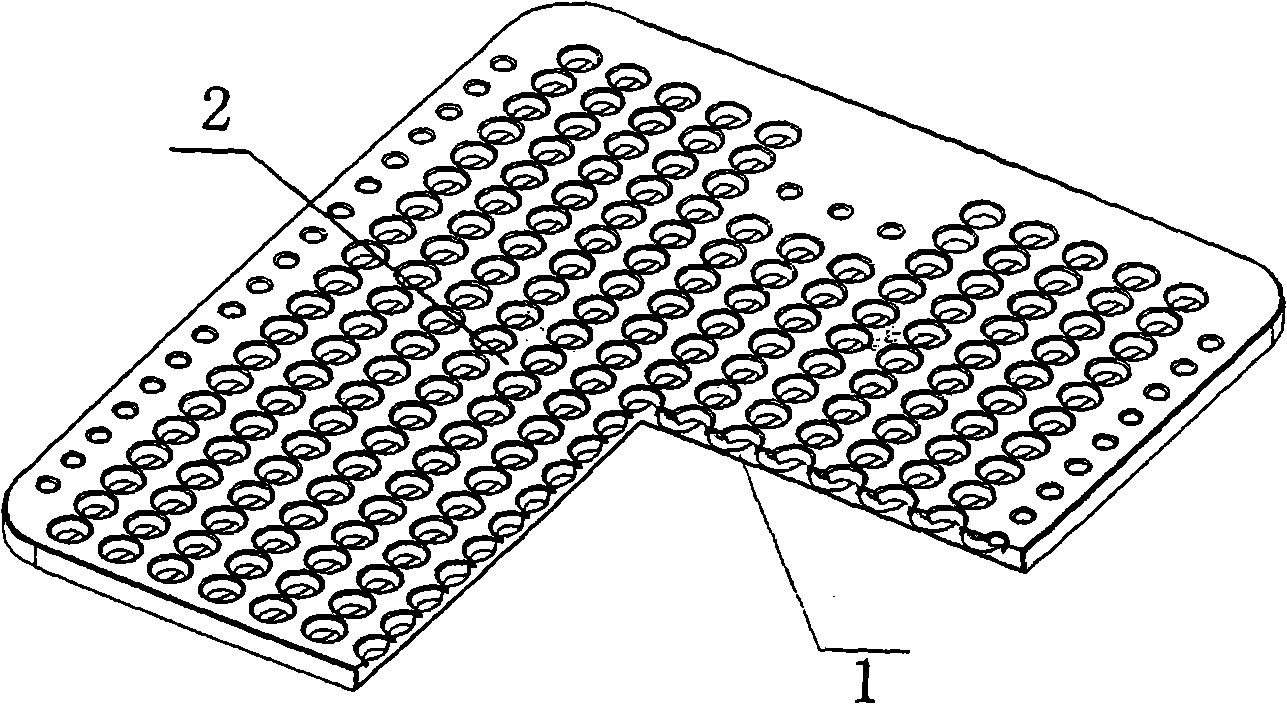

[0017] Such as figure 1 As shown, it is a partial cross-sectional view of the present invention, and the oil fume filter combined net plate is formed by nesting an air intake net plate 1 and an exhaust net plate 2 .

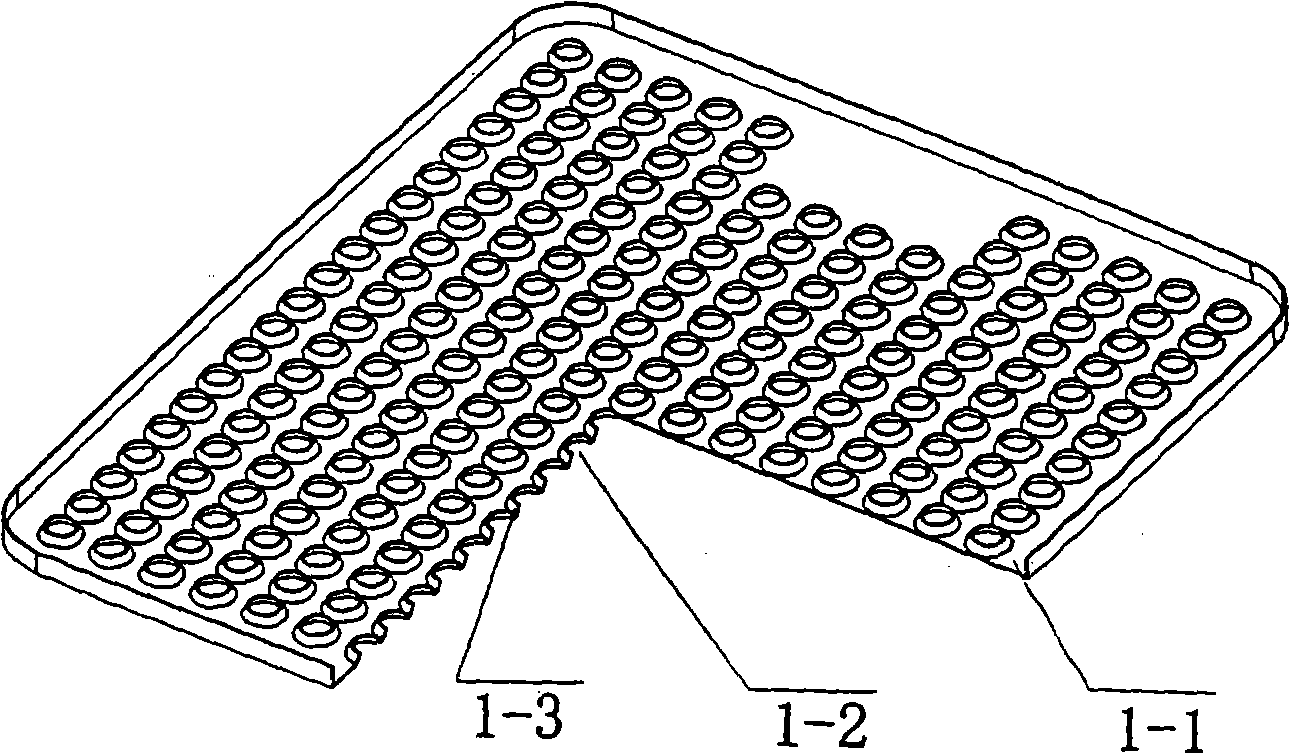

[0018] Such as figure 2 Shown is a partial cross-sectional view of the intake screen 1 . Circular air intake holes 1-2 are distributed on the air intake net bottom plate 1-1, and these air intake holes 1-2 together form an air intake hole array. The periphery of each air intake hole 1-2 extends toward the inside of the air intake screen 1 to form a stepped air guiding ring 1-3 with an open top, and all the air guiding rings 1-3 together form a stepped air guiding ring with an open top. Balloon array.

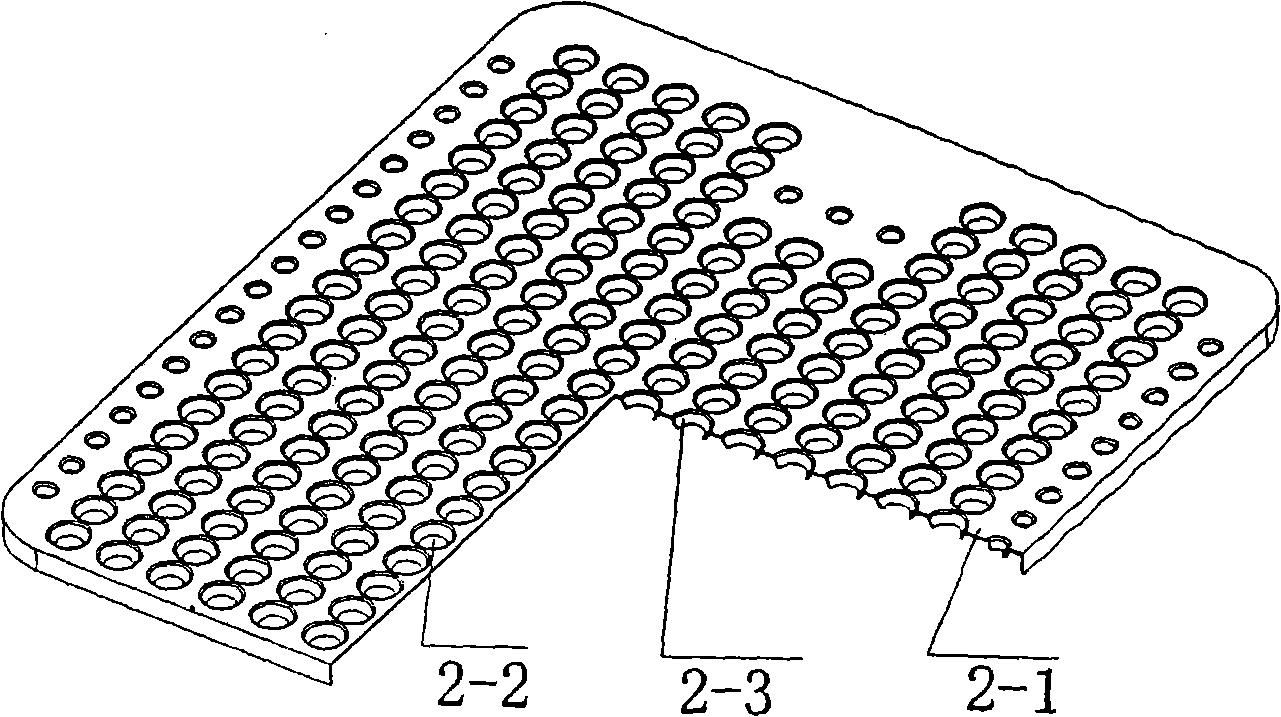

[0019] Such as image 3 Shown is a partial cross-sectional view of the exhaust grille 2 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com