Storage apparatus and method for reducing local pressure in a storage apparatus

A storage device and local pressure technology, which is applied in the direction of application, transportation and packaging, conveyor objects, etc., can solve the problems of rod-shaped items damage, local pressure increase, etc., and achieve the effect of local pressure reduction, smooth conveying, and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

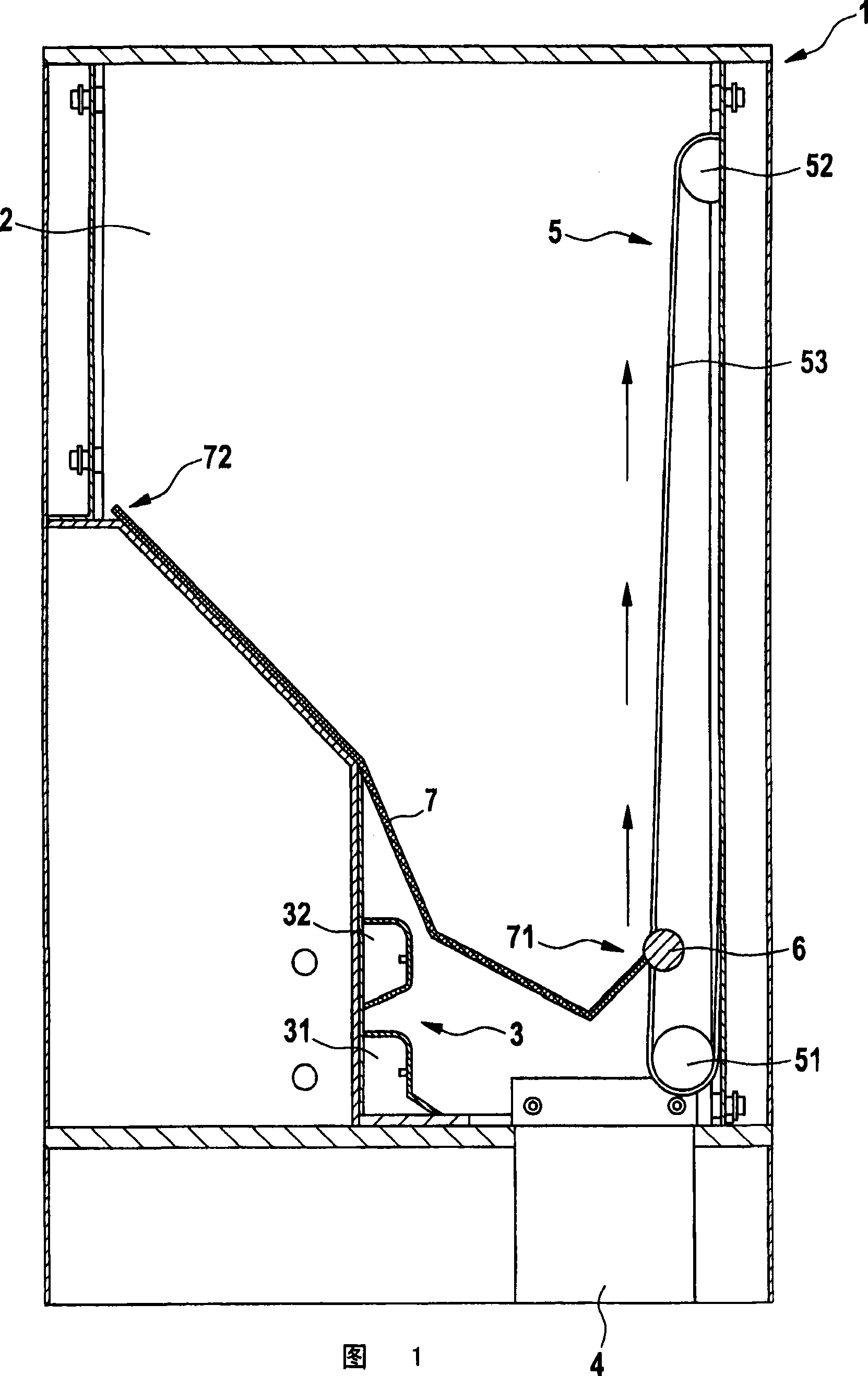

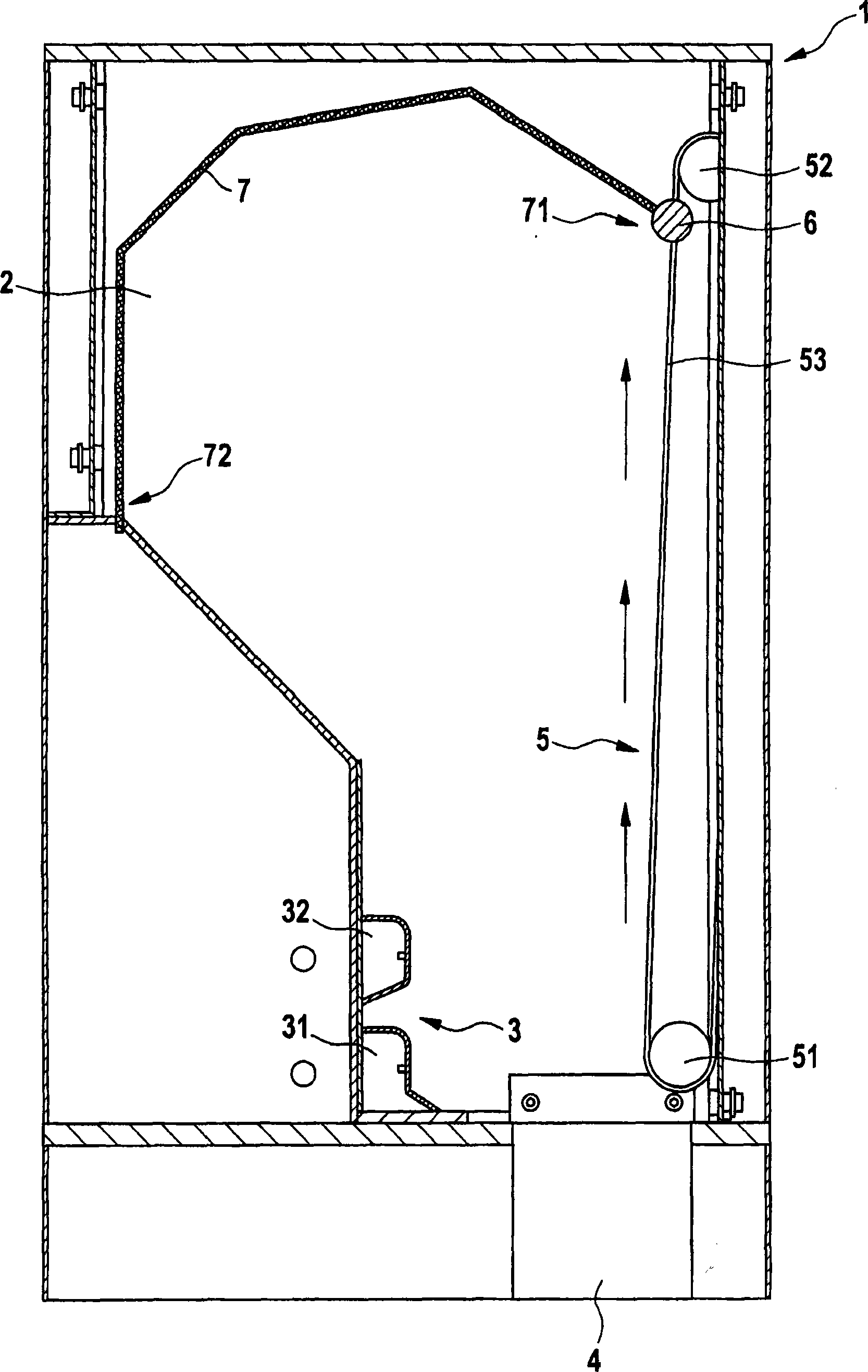

[0029] The device is used for storing filter rods during the cigarette manufacturing process. A filter rod is a single filter element or filter elements which are individually or separately used to filter cigarette smoke in filter cigarettes; said filter rods generally have a diameter of 5 mm to 9 mm, especially 7.5 mm, and a length of 60 mm mm to 180 mm and are made of a permeable material such as cellulose acetate fiber. The storages referred to in the present invention include all usual forms of storage, ie storage for long periods of time as well as temporary storage for compensating time differences between individual processing steps (so-called "buffers"). Instead of filter rods, the device can of course also be used for storing other rod-shaped items of the tobacco processing industry that need to be protected from mechanical damage, i.e. items at least partially in the shape of an elongated, generally cylindrical rod or pin, Like cigarettes.

[0030] exist figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com