Skid shoe-free swash plate-free axial short piston pump

A short plunger and swash plate technology is applied in the field of plunger pumps without sliding shoes and swash plates, which can solve the problems of low volumetric efficiency, low output pressure, and many friction pairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

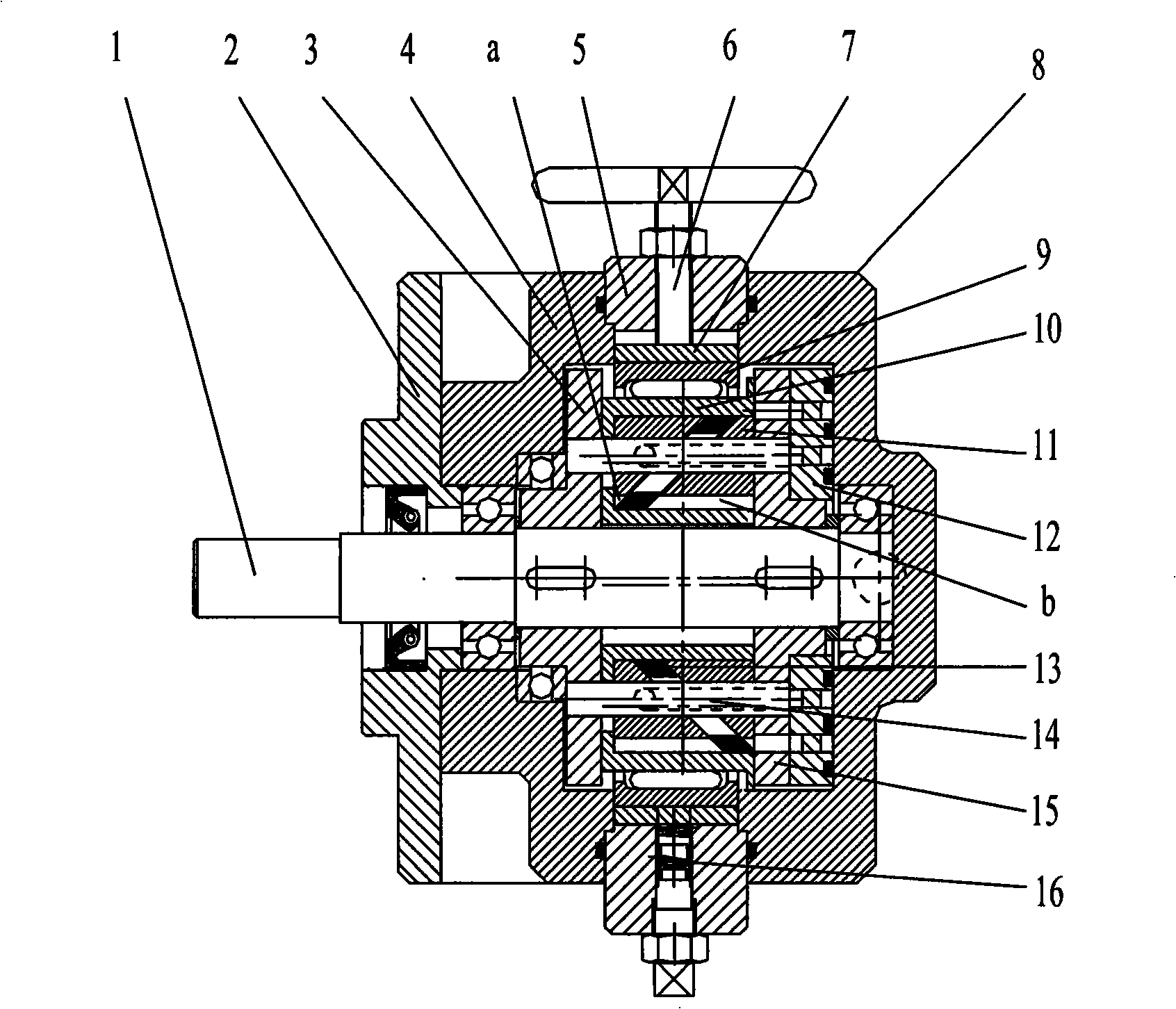

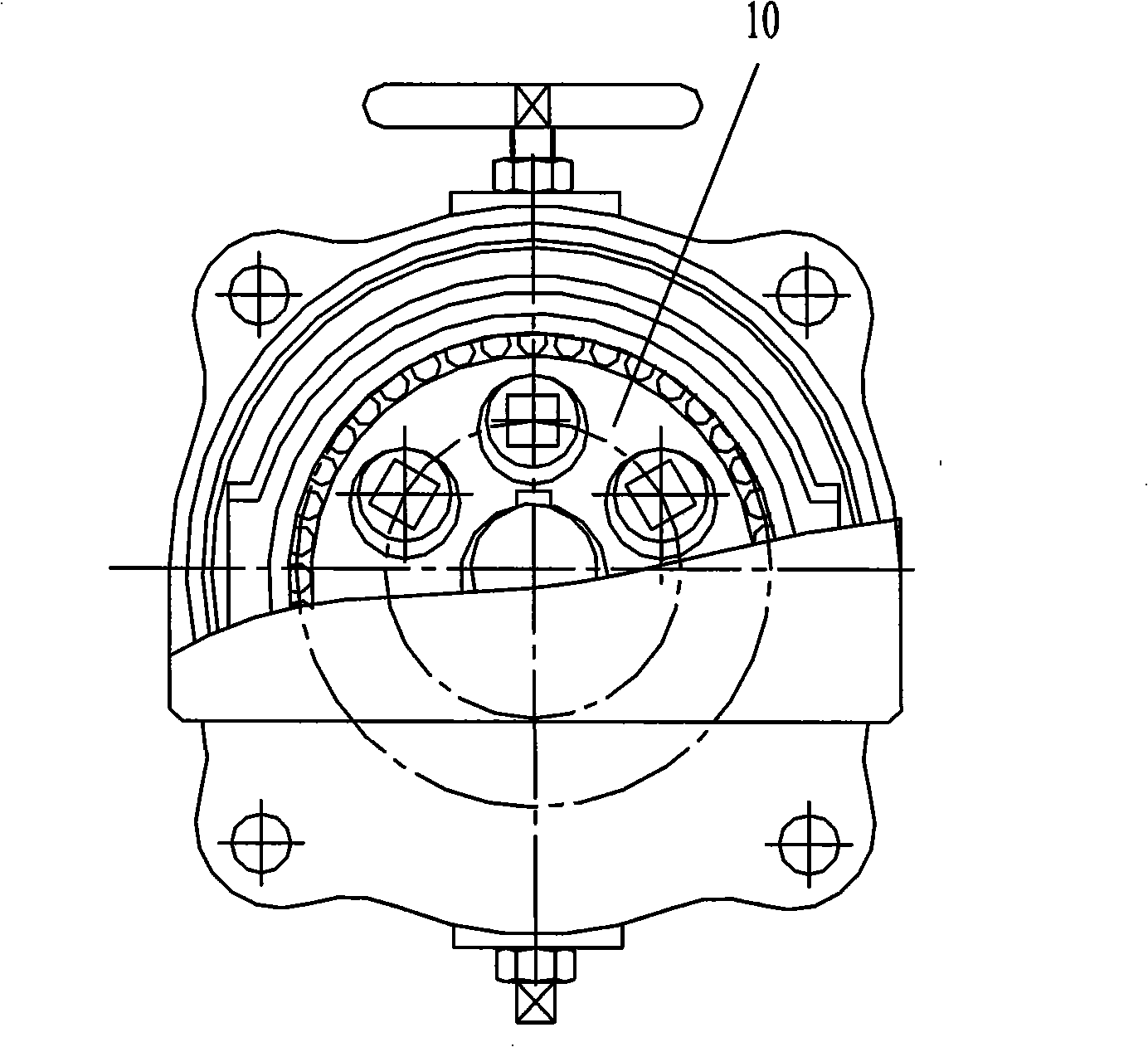

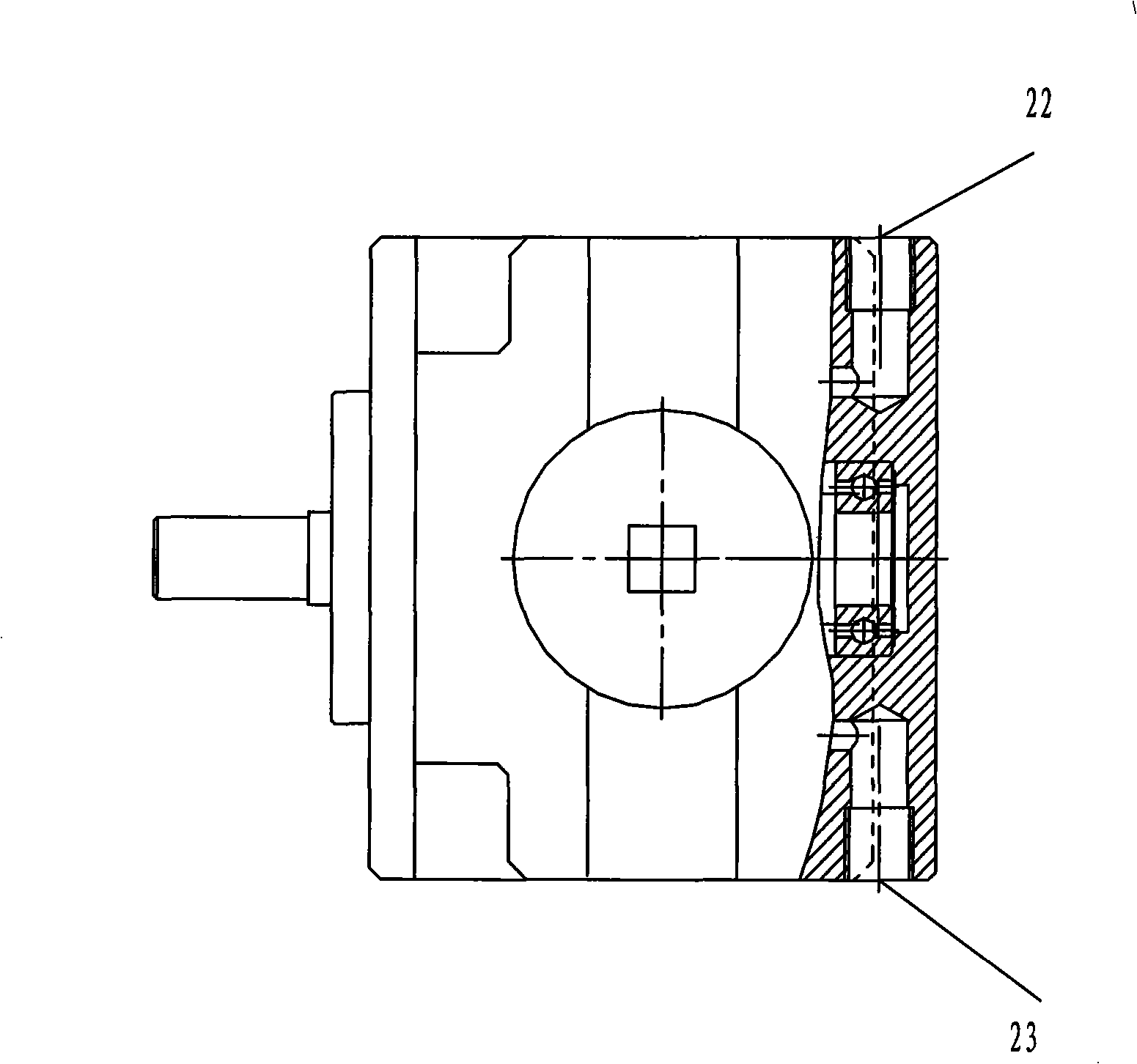

[0015] figure 1 , figure 2 and image 3 Shown is a shoeless and swashplate axial short piston pump with six cylinder units. The cylinder body 10 of the pump is provided with 6 cylinder holes, the cylinder body 10 is installed in the support ring 7 through the needle bearing 9, the support ring 7 can move up and down in the housing 5, and the cylinder body 10 can pass through the support ring 7 Needle bearing 9 rotates freely. Each cylinder hole of the cylinder block 10 is equipped with a cylinder unit, which includes a chute shaft composed of a slanted end shaft 11, and a slanted short plunger 13 is housed in the chute of the chute shaft. Also can adorn two inclined-plane short plungers 13 to reduce the inclination angle of inclined-plane short plunger, prevent from being stuck in the rotation. The chute shaft is fixed on the front fender 3 and the rear fender 15 through the small shaft 14 of the square section, and the front fender 3 and the rear fender 15 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com